MOULD MAKING

Lanxin's high-precision molding development includes plastic injection molding, compression molding, Lsr injection molding, and die-cutting molds. Covering industries such as consumer electronics, communications, new energy, medical, household appliances and others. The precision control reaches the high-end level of the industry and meets the needs of various manufacturing industries.

There are two independent mold making workshops in Lanxin, one of them is an intelligent production workshop. In-depth cooperation with various mold development pioneers, using advanced technology to provide strong support for bulk production, with a monthly output of up to 10 sets of precision molds.

The following mainstream materials are selected:

718, 718H, 738, S136H, S136, NAK80, 2344, 8407, P20, H13, etc...

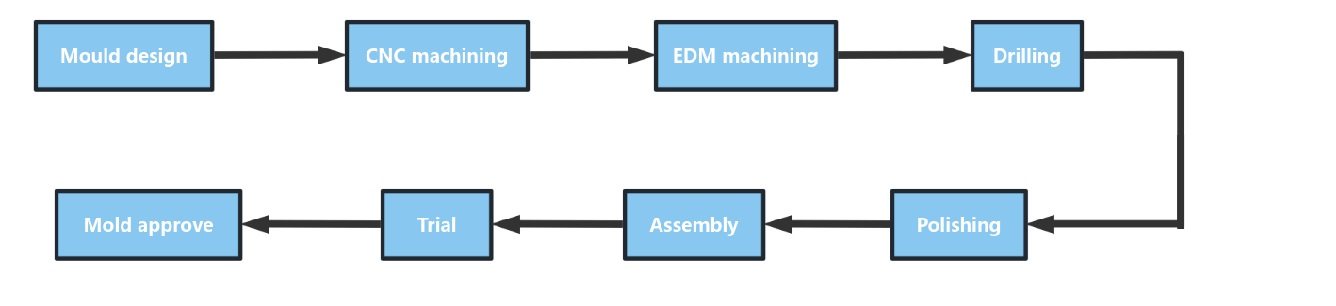

Mold Making Process

Lanxin can provide one-stop customization services. We are not only manufacturers of silicone and plastic products but also can help you design and create molds. The following are the critical steps in making molds for silicone and plastic products.

Workshop and equipments

MAKINO CNC machine

GF AgieCharmilles and Japan Sodick EDM

Why choose us

Professional Team

Advanced Equipments

Technical Support

Quality Assure

We have a team of dedicated and highly skilled engineers with extensive industry knowledge and practical experience.

We have a dedicated mold production workshop equipped with advanced mold processing equipment.

In order to maintain long-term cooperation with our customers, we follow up on the production status of each set of molds, regularly clean and maintain them, and provide remote video conference communication.