Product description

| ITEM | 3M adhesive acrylic tape | ||

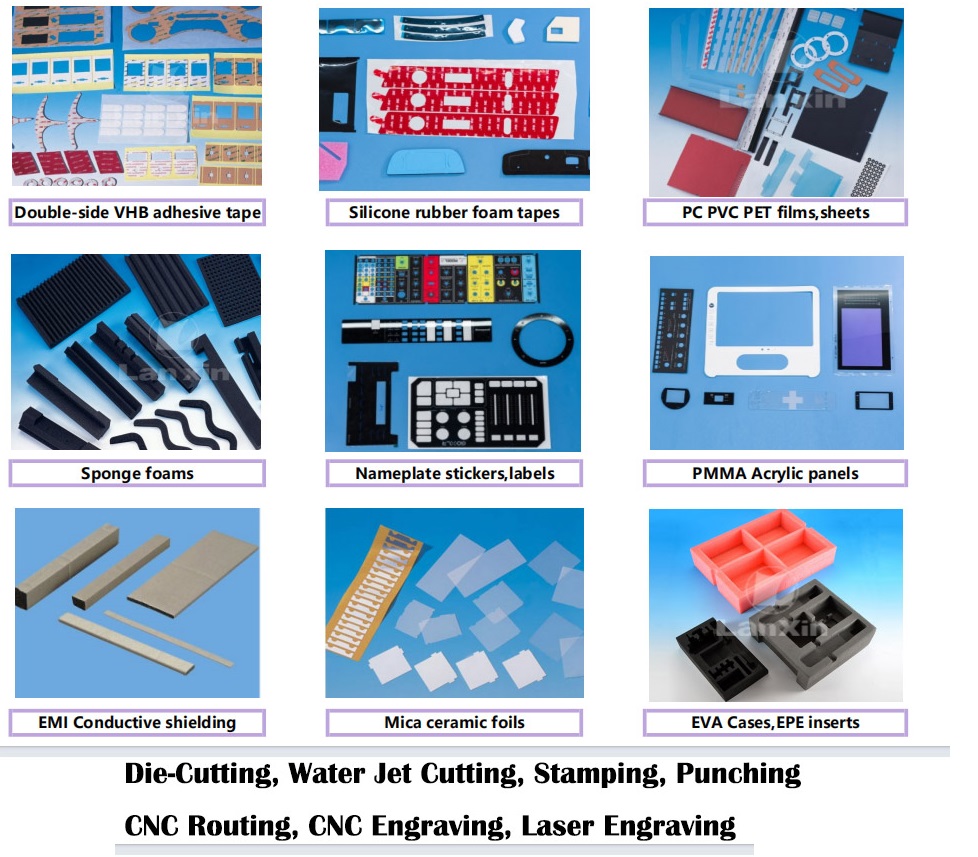

| Material | Die-Cutting materials can improve efficiency and output quality. Here are just a few of the materials that we can die-cut:

|

| Certificate | IATF 16949:2016 / ISO 9001:2015 / ISO 45001:2018 / ISO 14001:2015 /REACH/ROHS/MSDS/LFGB/F D A |

| Drawing Format | .stp / .step / .igs /.stl /.dwg / .pdf |

| Cutting types | Rotary die-cutting, flatbed die-cutting, waterjet cutting, CNC, etc... |

Adhesive acrylic tape is a versatile solution with extensive applications across multiple industries. In the electronics sector, it bonds components securely while providing electrical insulation and shock absorption, ensuring the stability of devices. In construction, it serves as an effective sealant for joints, offering weather resistance and preventing water infiltration. In the automotive field, adhesive acrylic tape is used for interior trims and exterior moldings, providing a strong hold and resistance to vibrations.

Lanxin Company excels in producing high-quality adhesive acrylic tape. Our professional edge lies in advanced formulation technology, enabling us to customize the tape's viscosity, thickness, and adhesive strength according to specific needs. With state-of-the-art coating and slitting equipment, we ensure uniform thickness and precise dimensions. Rigorous quality control processes, from raw material inspection to finished product testing, guarantee consistent performance. Whether for high-temperature applications, heavy-duty bonding, or delicate surface attachment, Lanxin's adhesive acrylic tape delivers reliable, long-lasting adhesion and meets the most demanding requirements.

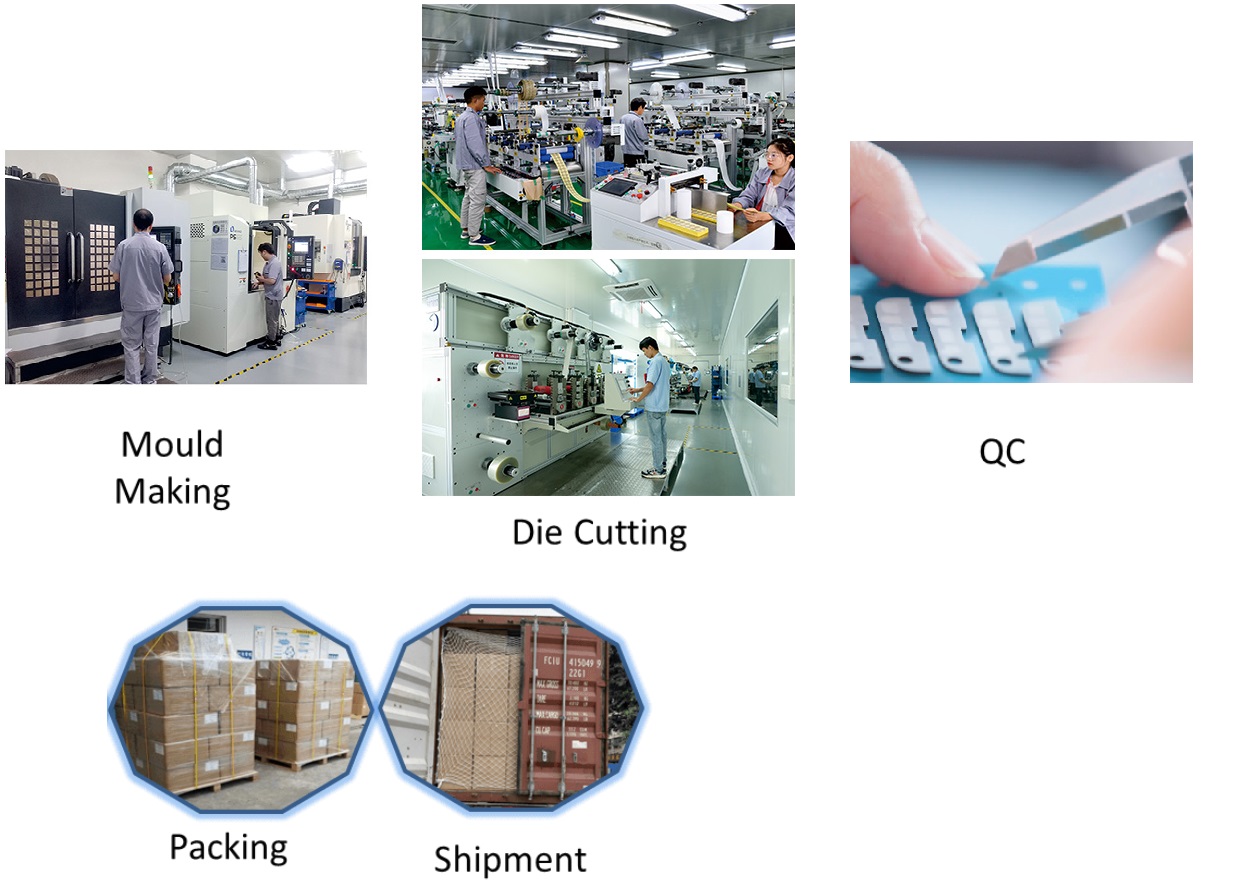

The production of die-cutting adhesive tapes of Lanxin

As a 3M authorized partner since 2009, Lanxin has in-depth knowledge of 3M materials. Our advanced die-cutting technology ensures precise shaping of tapes with 3M 300LSE adhesive, maintaining the integrity of the adhesive properties. We can customize the tapes according to specific needs, whether it's adjusting the size, shape, or adding additional functional layers. Rigorous quality control procedures are in place, guaranteeing that each die-cutting adhesive tape meets the high standards of 3M and our customers. This allows us to provide reliable, high-quality adhesive tapes for applications in automotive, medical, and electronics industries, among others.

Images for reference

Producing Process

Quality standard

Lanxin's insulation materials quality is 100% according to ISO9001 Standard. We seriously take care of the quality control from IQC to OQC, throughout each step of the production.

Lanxin dedicated to strict quality control and thoughtful customer service. We strive to exceed our customers' expectation in all aspects of product manufacturing process, and recognize our great responsibilities to our customers.

FAQ

Q1: How soon can I get a precise quotation for custom die cutting insulated materials ?

A1: Please send us your inquiry by email or phone call. Once we confirm the design (Feature details with parameters), material, color, qty, we can provide quotation within 24 HOURS.

Q2: Can I get a free sample, how long will it take?

A2: a. For standard products we have in stock, YES for free sample, but the express fee will be charged in advance. Mostly, it takes 3-10 days.

b. For custom products, sample fee is determined by the detailed sample requirements. Normally, it takes 7-15 days.

Q3: Can you make custom parts based on my sample?

A3: Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing for production.