Plastic Iniection Molding

Injection molding is one of the most common processes used to produce plastic components.

It's most often used for the manufacturing plastic parts at scale due to its low material waste and low cost per part. It’s an ideal for producing high volumes of low-cost plastic parts with high tolerance precision, repeatability and little to no finishing required.

We have two mature plastic product production workshops and over 20 injection molding machines to maximize customer production capacity. Once you confirm the price, we will issue a Design for Manufacturability report (DFM) of the product.

Material

The following are plastic raw materials commonly used in various industrial manufacturing:

☐ABS ACM ☐PMMA(Acrylic), POM(Acetal), PET (Polyethylene terephthalate)

☐PE, PVC, PS, PP, PLA, PA(Nylon), PC, PPS(Noryl), PU, PBT, PEEK and PES

☐TPO TPE(Thermoplastic elastomer) TPU(Thermoplastic polyurethane)

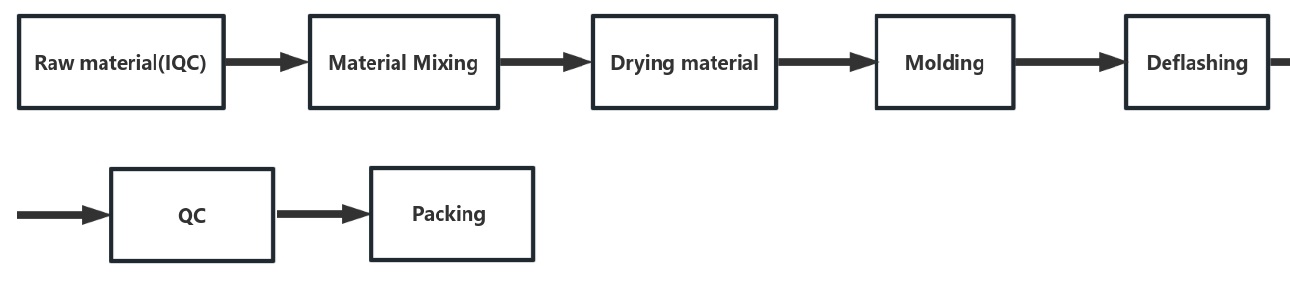

Production Process

Quality Control

100% inspection for order,we seriously take care of the quality control from IQC to OQC, throughout each step of the production. Let us show you our quality control:

For raw materials, we’ll do the IQC in time. All materials are procured only from the verified suppliers, who have implemented and maintain certified quality management systems in their plants. With full certificates, such as RoHs, Reach, MSDS, FDA, LFGB, UL, EN549, BPA free, EN71, and so on;

For pre-production samples, we'll provide several pieces to our clients for assembly and function testing. We will seal the samples in time once they're approval.

For Bulk Production, we'll do the IPQCS & PQC (Multiple Sampling Inspection) during production and we'll do the FQC (Sampling Inspection) after deburr or breaking sharp edges. In order to timely find problems, solve problems, reduce defective products, reduce manufacturing costs.

After packing and assembling, we'll do the OQC (Sampling Inspection) to make sure the final goods are qualified.

Inspection instrument