Product description

| ITEM | Closed cell foam,foam gaskets |

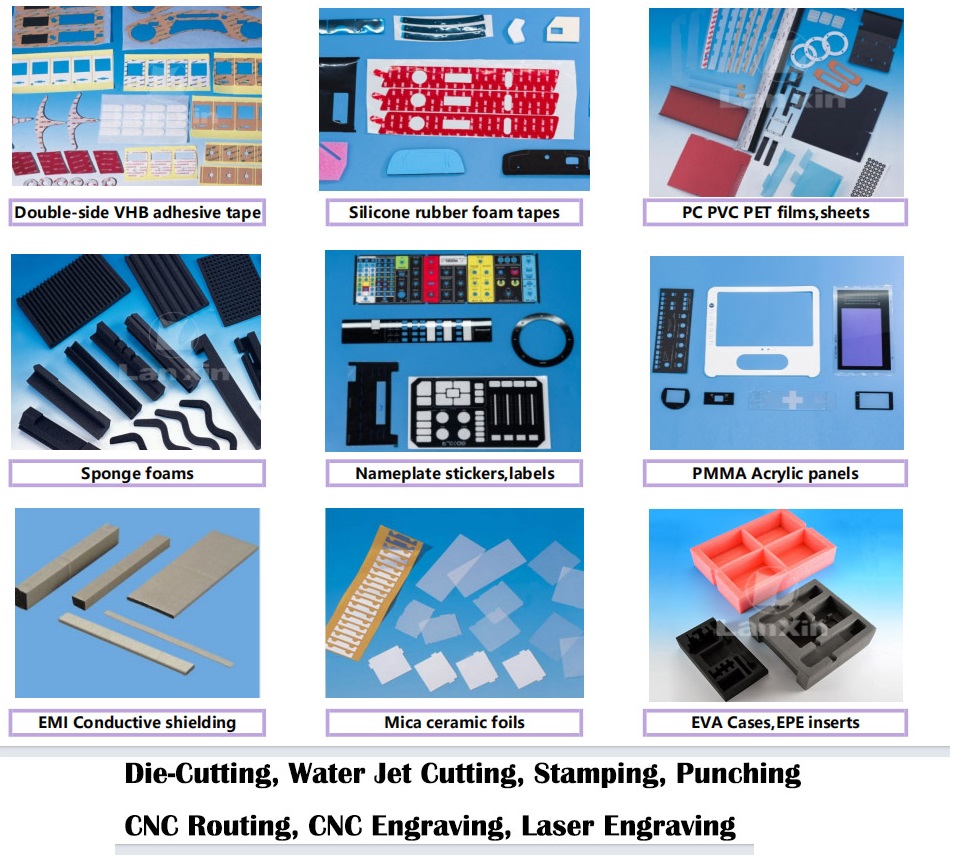

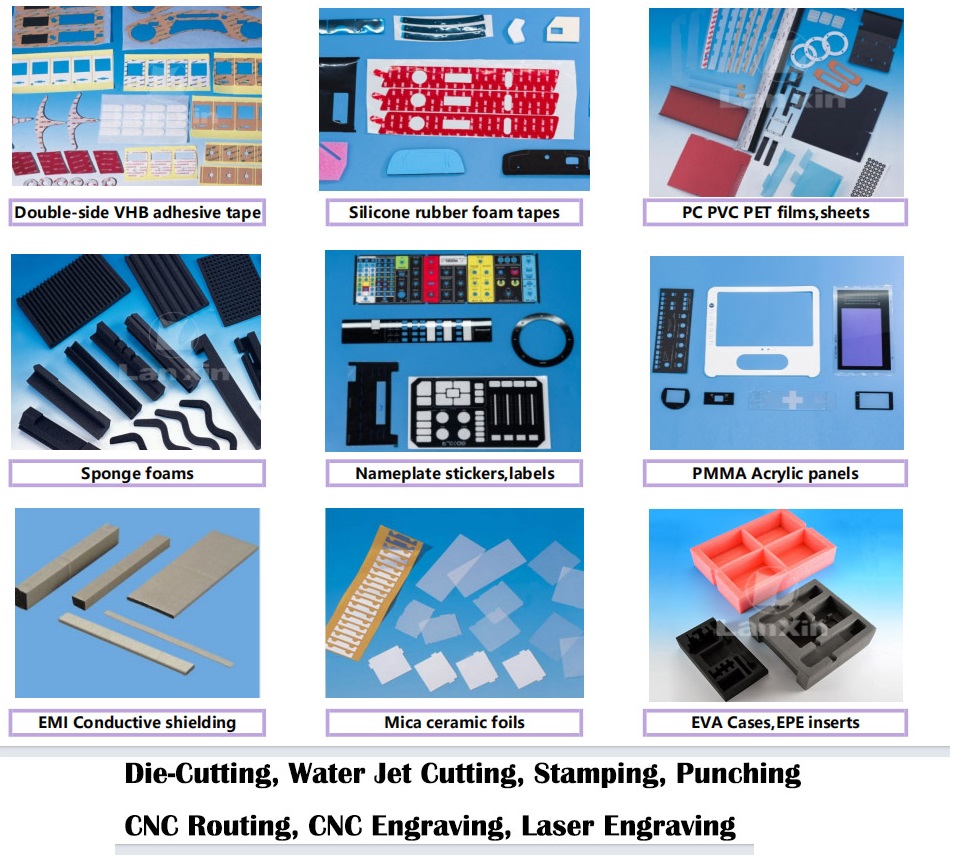

| Material | Die-Cutting materials can improve efficiency and output quality. Here are just a few of the materials that we can die-cut:

| Pressure-Sensitive Tapes Gaskets Films Foams Foils Papers Rubbers Label Stocks VHB Specialty Materials

|

|

| Certificate | IATF 16949:2016 / ISO 9001:2015 / ISO 45001:2018 / ISO 14001:2015 /REACH/ROHS/MSDS/LFGB/F D A |

| Drawing Format | .stp / .step / .igs /.stl /.dwg / .pdf |

| Cutting types | Rotary die-cutting, flatbed die-cutting, waterjet cutting, CNC, etc... |

Foam gaskets, especially those made of closed cell foam material, have distinct material characteristics and wide-ranging applications in various industries. The details are as follows:

Superior Cushioning Performance: Poron closed cell foam gaskets are known for their excellent cushioning ability. They have a fine and uniform cell structure that can effectively absorb and disperse impact forces. Whether it's from external vibrations or sudden impacts, these closed cell foam gaskets can protect the components they are installed with from damage, making them ideal for applications where shock resistance is crucial.

High Compressibility and Recovery: Closed cell foam exhibit high compressibility, allowing foam gaskets to be easily compressed to fit into different spaces and conform to the shapes of irregular surfaces. Moreover, they have remarkable recovery properties.

Good Sealing Property: The dense structure of closed cell foam sponge gaskets, particularly Poron ones, gives them excellent sealing capabilities. They can effectively block the passage of air, water, and dust, preventing external substances from entering and internal substances from leaking out. This makes them suitable for applications requiring strict sealing, such as in electronic devices and automotive components.

Low Density and Lightweight: Foam sponge gaskets are generally of low density and lightweight, which is advantageous in applications where weight is a concern. Like automotive industries, using these foam gaskets can help reduce the overall weight of the equipment without sacrificing performance.

Good Chemical Resistance: Poron foam sponge gaskets have good resistance to a variety of chemicals. They are not easily affected by acids, alkalis, and common solvents, which ensures their stability and durability in different chemical environments. This property extends their service life and makes them suitable for use in harsh industrial settings.

Excellent Insulation material Properties: Closed cell foam possess good electrical and thermal insulation properties. This makes foam gaskets useful in electronic and electrical applications to prevent electrical leakage and thermal conduction, enhancing the safety and performance of the equipment.

Lanxin are specialized in foam gasket manufacturing, our products are from Poron, Rogers, Nitto and

other famous brand suppliers.

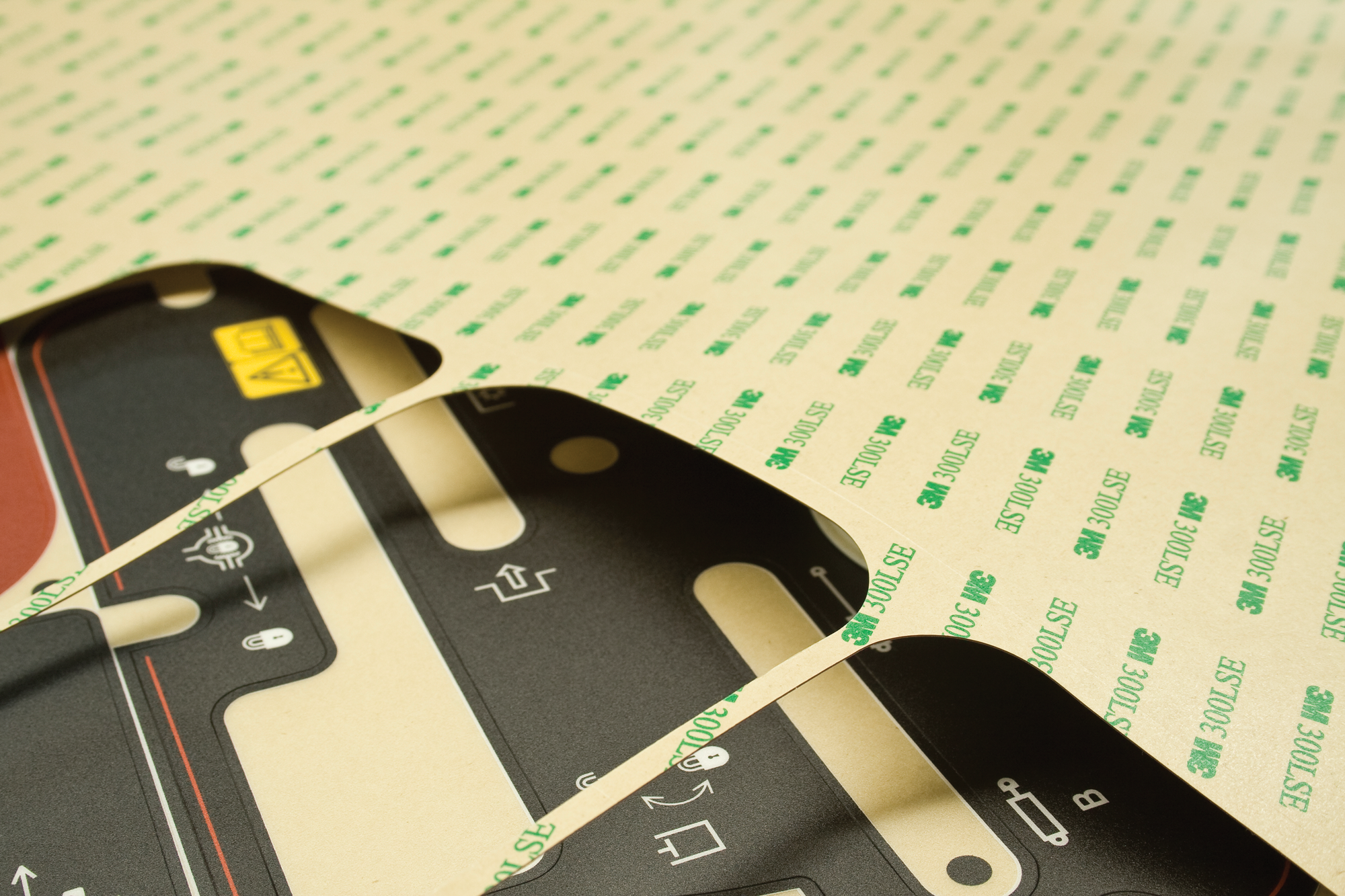

Images for reference

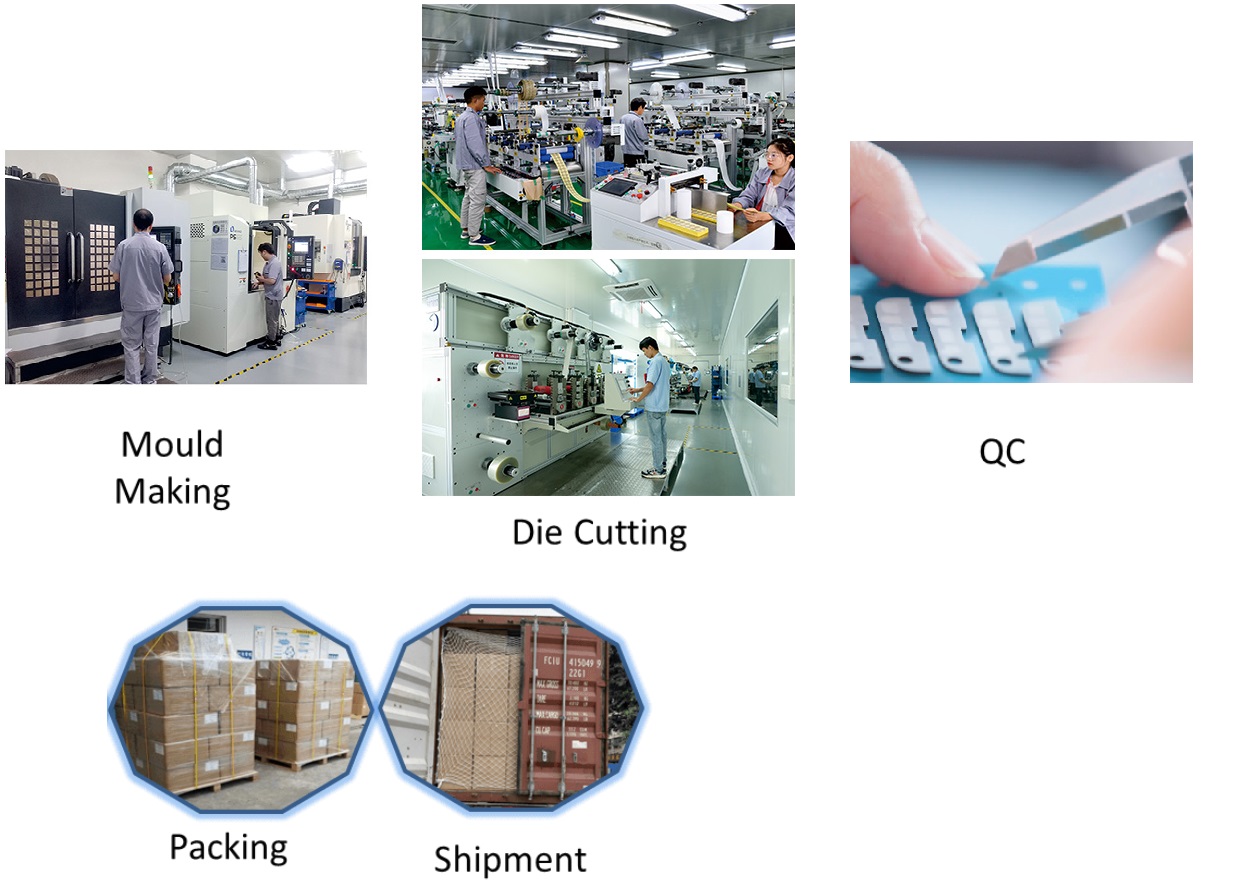

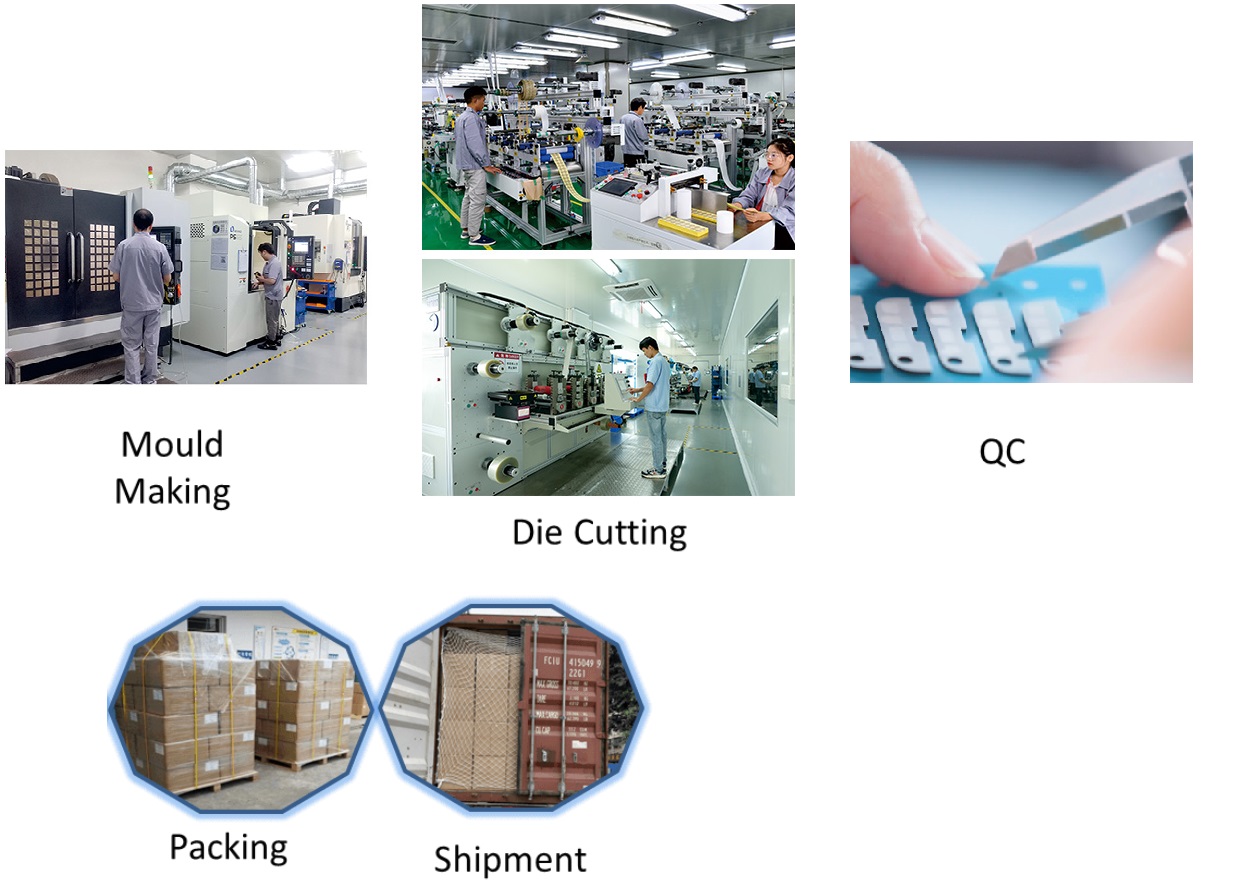

Producing Process

Quality standard

Lanxin's insulation materials quality is 100% according to ISO9001 Standard. We seriously take care of the quality control from IQC to OQC, throughout each step of the production.

FAQ

Q1: How soon can I get a precise quotation for custom die cutting insulation materials ?

A1: Please send us your inquiry by email or whatsapp. Once we confirm the design (Feature details with parameters), material, color, qty, we can provide quotation within 24 HOURS.

Q2: Can I get a free sample, how long will it take?

A2: a. For standard products we have in stock, YES for free sample, but the express fee will be charged in advance. Mostly, it takes 3-10 days.

b. For custom products, sample fee is determined by the detailed sample requirements. Normally, it takes 7-15 days.

Q3: Can you make custom parts based on my sample?

A3: Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing for production.