Product Description

| ITEM | Poron foam, adhesive Poron foam |

Size | Thickness:0.05-60mm. Width: 5mm/10mm/15mm/20mm/50mm. Length: 5M/10M/50M/100M. Custom shapes and sizes can be achieved through die-cutting, allowing for precise and tailored solutions. |

| Certificate | IATF 16949:2016 / ISO 9001:2015 / ISO 45001:2018 / ISO 14001:2015 /REACH/ROHS/MSDS/LFGB/ FDA |

| Drawing Format | .stp / .step / .igs /.stl /.dwg / .pdf |

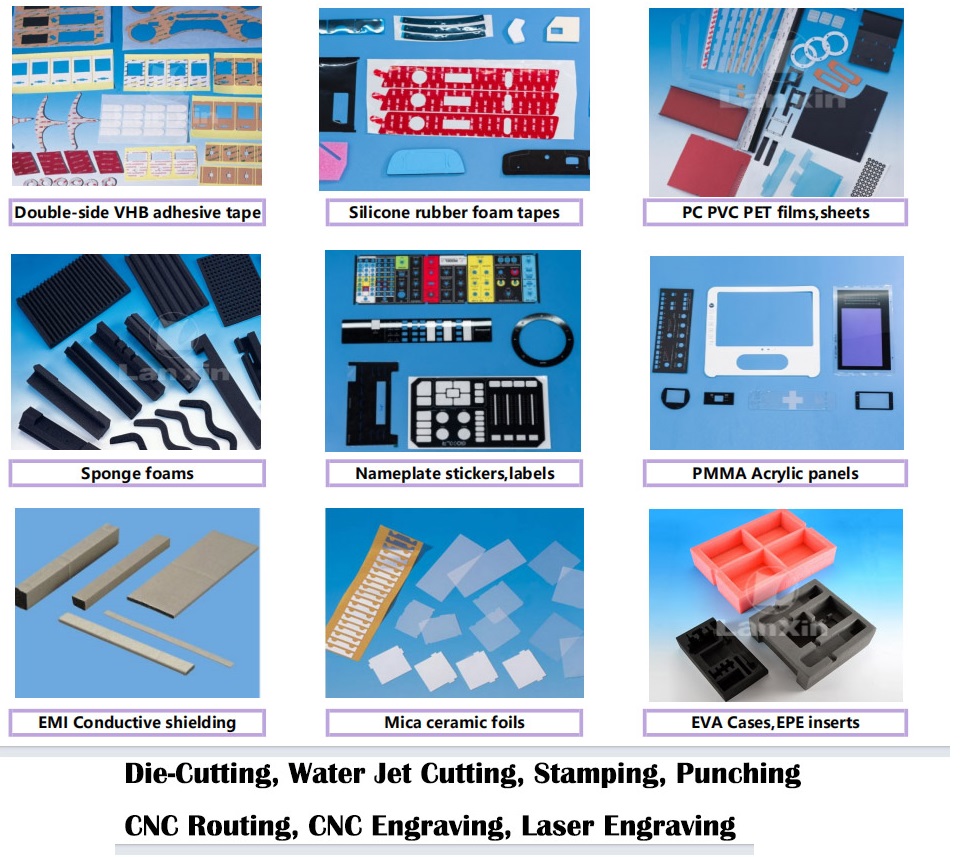

| Cutting types | Rotary die-cutting, flatbed die-cutting, waterjet cutting, CNC, etc... |

This silicone-based Poron foam excels in harsh conditions, withstanding a wide range of temperatures, chemicals, and moisture. Ideal for gaskets, seals, and cushioning components in automotive, electronics, and industrial applications, it delivers reliable performance for vibration dampening, gap filling, and protection against dust and liquids.

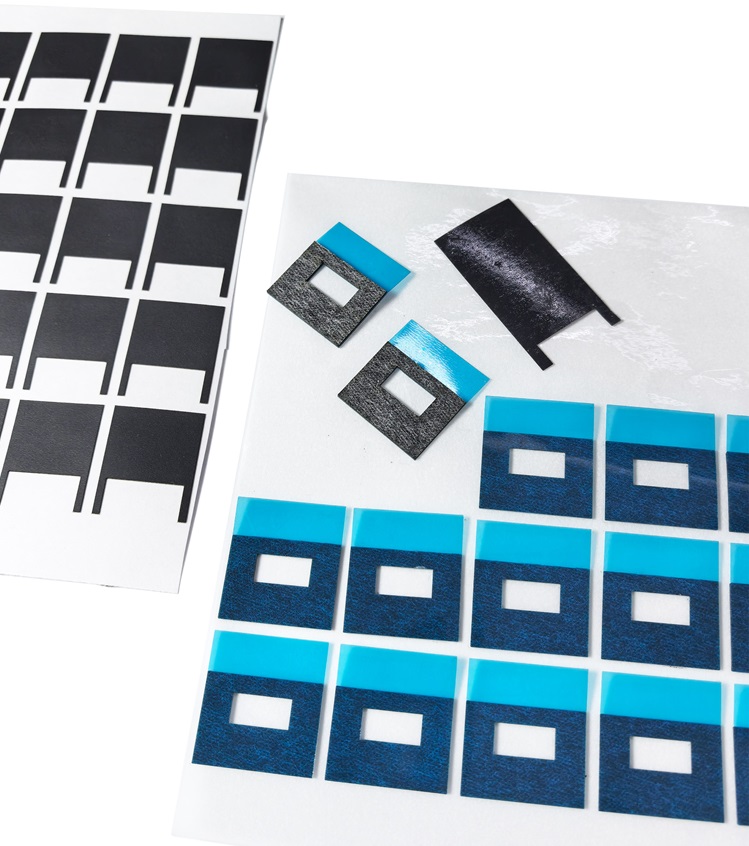

Images Reference

Related Products

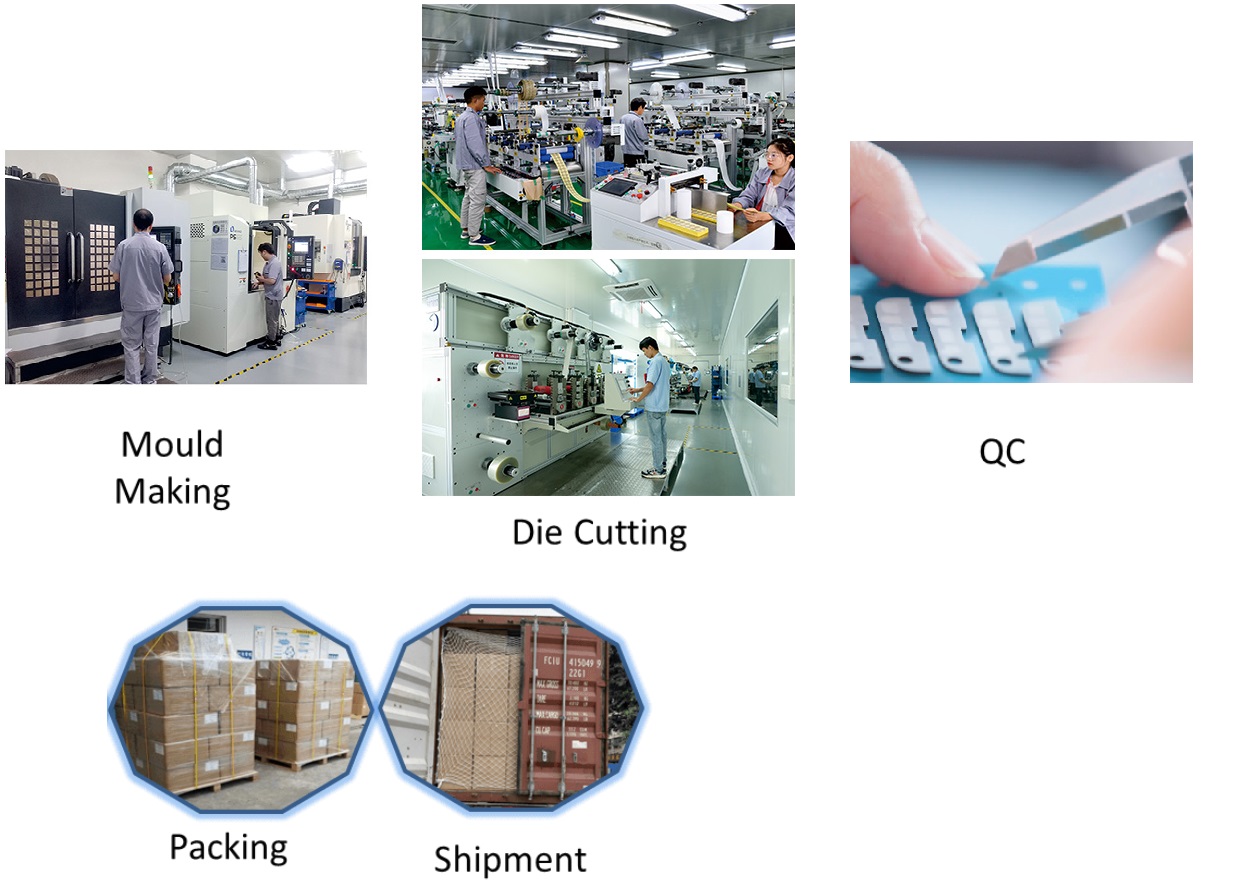

Producing Process

Quality Standard

Lanxin's insulation materials quality is 100% according to ISO9001 Standard. We seriously take care of the quality control from IQC to OQC, throughout each step of the production.

FAQ

Q1: How soon can I get a precise quotation for custom die cutting insulated materials ?

A1: Please send us your inquiry by email or phone call. Once we confirm the design (Feature details with parameters), material, color, qty, we can provide quotation within 24 HOURS.

Q2: Can I get a free sample, how long will it take?

A2: a. For standard products we have in stock, YES for free sample, but the express fee will be charged in advance. Mostly, it takes 3-10 days.

b. For custom products, sample fee is determined by the detailed sample requirements. Normally, it takes 7-15 days.

Q3: Can you make custom parts based on my sample?

A3: Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing for production.