Product description

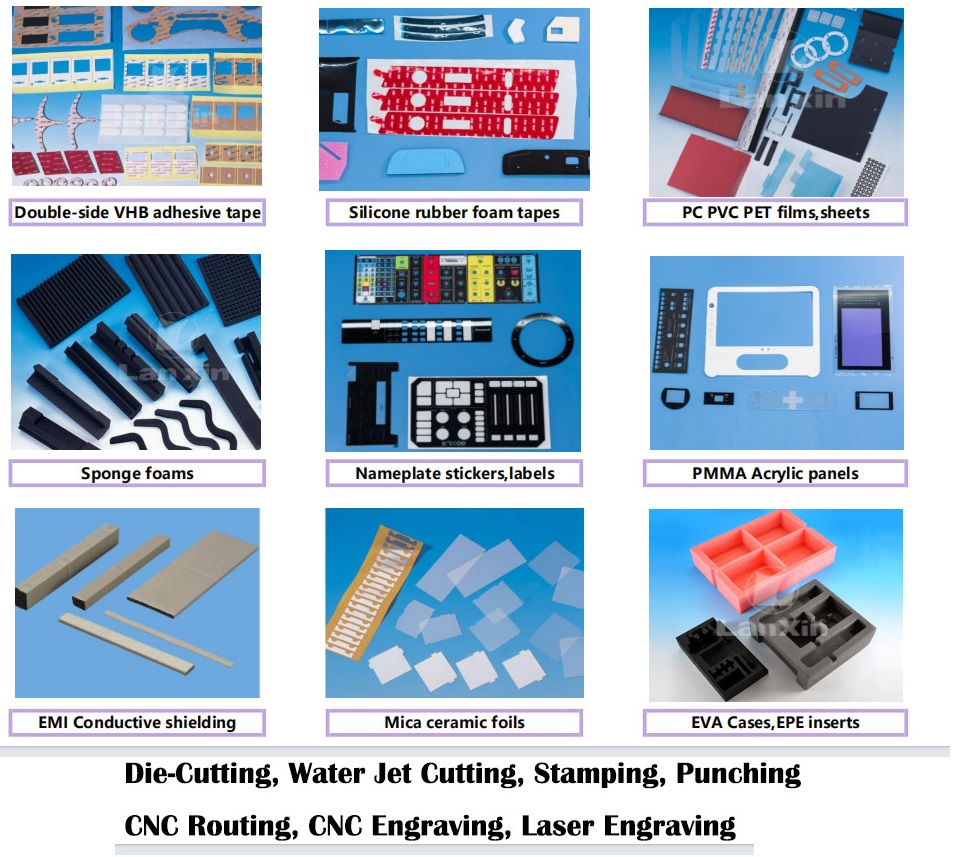

Many of the die-cutting materials we work with are already used in a variety of industries:

| Certificate | IATF 16949:2016 / ISO 9001:2015 / ISO 45001:2018 / ISO 14001:2015 /REACH/ROHS/MSDS/LFGB/F D A |

| Drawing Format | .stp / .step / .igs /.stl /.dwg / .pdf |

| Cutting types | Rotary die-cutting, flatbed die-cutting, waterjet cutting, CNC, etc... |

Die cutting VHB adhesive tapes have become a staple in various industries. Like 3M VHB adhesive tape 5952 is well - renowned. It features a modified acrylic adhesive on both sides of a highly conformable acrylic foam core. Die cutting VHB adhesive tape can replace traditional mechanical fasteners like rivets, welding, and screws, or liquid adhesives. With its excellent gap-filling capabilities, it creates a permanent seal against water and moisture. The 5952 VHB adhesive tape well to a wide range of substrates, including powder-coated paints and irregular surfaces, and is commonly used in applications such as bonding and sealing panels to frames, display bonding, signage, and decorative material bonding.

Lanxin Company has distinct professional advantages in die cutting VHB adhesive tapes. As an authorized long-term partner of 3M, we have in - depth knowledge of 3M's product lines and can obtain different models of VHB adhesive tapes at competitive prices. Our well-stocked inventory ensures prompt order fulfillment, regardless of whether it's a small - scale or large-volume requirement. Equipped advanced die-cutting machinery, we can achieve an astonishing dimensional accuracy of up to ±0.01mm. This precision allows us to cut the VHB adhesive tapes into intricate shapes as per customer specifications. Our team of experienced engineers is also available to provide customized solutions, tailoring the tape's properties such as adhesive strength and thickness to meet specific application needs. Rigorous quality control processes are implemented at every production stage, guaranteeing that the die cutting VHB adhesive tapes from Lanxin meet the highest industry standards, making us a reliable choice for all die cutting VHB adhesive tape requirements.

Images for reference

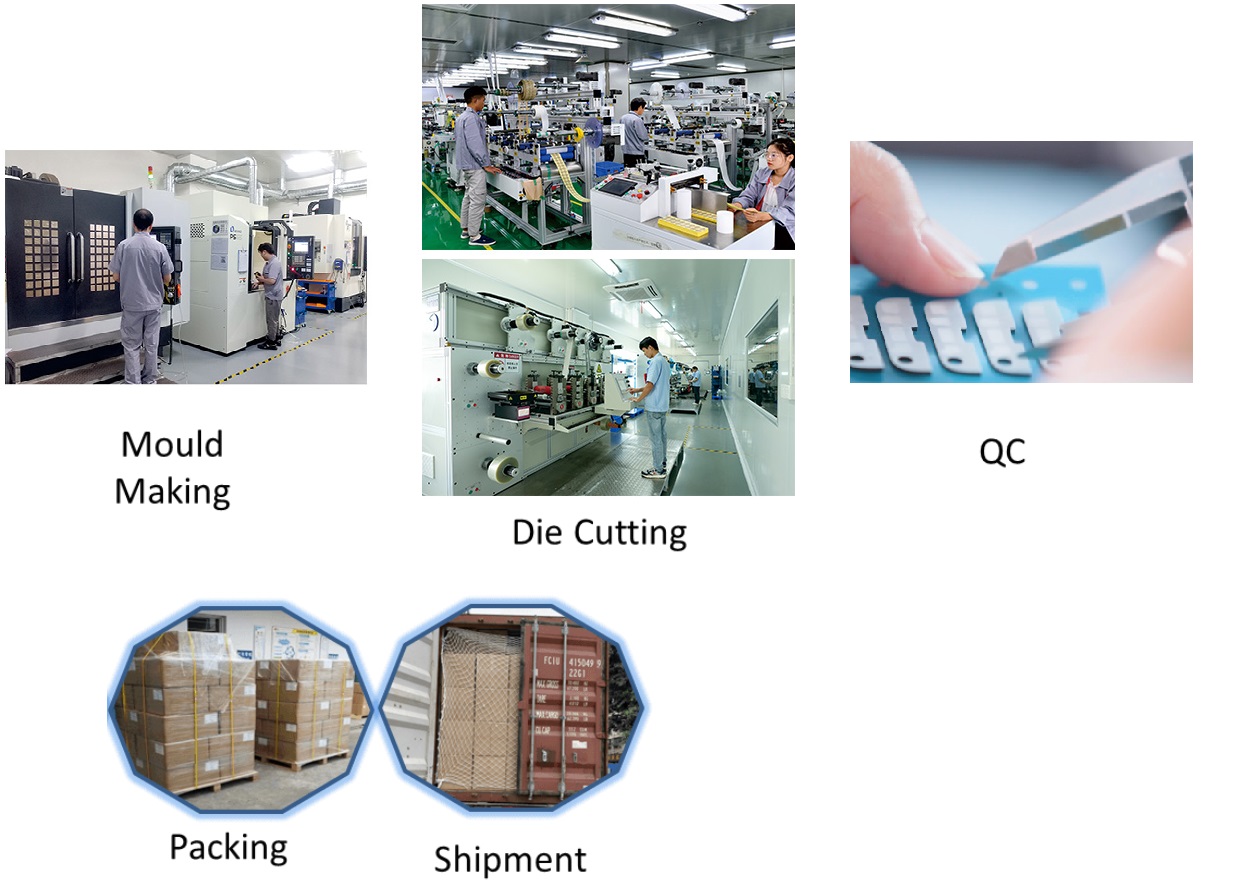

Producing Process

Quality standard

Lanxin's insulation materials quality is 100% according to ISO9001 Standard. We seriously take care of the quality control from IQC to OQC, throughout each step of the production.

Lanxin dedicated to strict quality control and thoughtful customer service. We strive to exceed our customers' expectation in all aspects of product manufacturing process, and recognize our great responsibilities to our customers.

FAQ

Q1: How soon can I get a precise quotation for custom die cutting insulated materials ?

A1: Please send us your inquiry by email or phone call. Once we confirm the design (Feature details with parameters), material, color, qty, we can provide quotation within 24 HOURS.

Q2: Can I get a free sample, how long will it take?

A2: a. For standard products we have in stock, YES for free sample, but the express fee will be charged in advance. Mostly, it takes 3-10 days.

b. For custom products, sample fee is determined by the detailed sample requirements. Normally, it takes 7-15 days.

Q3: Can you make custom parts based on my sample?

A3: Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing for production.