Product description

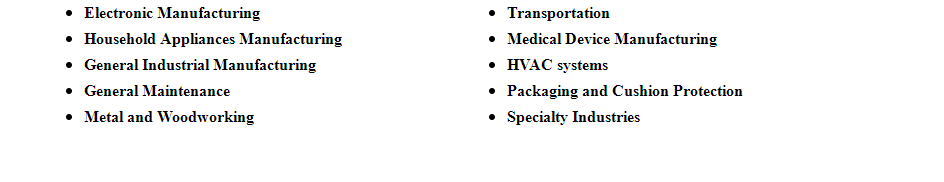

Many of the die-cutting materials we work with are already used in a variety of industries:

| ITEM | 3M TESA Nitto double-side adhesive tape | ||

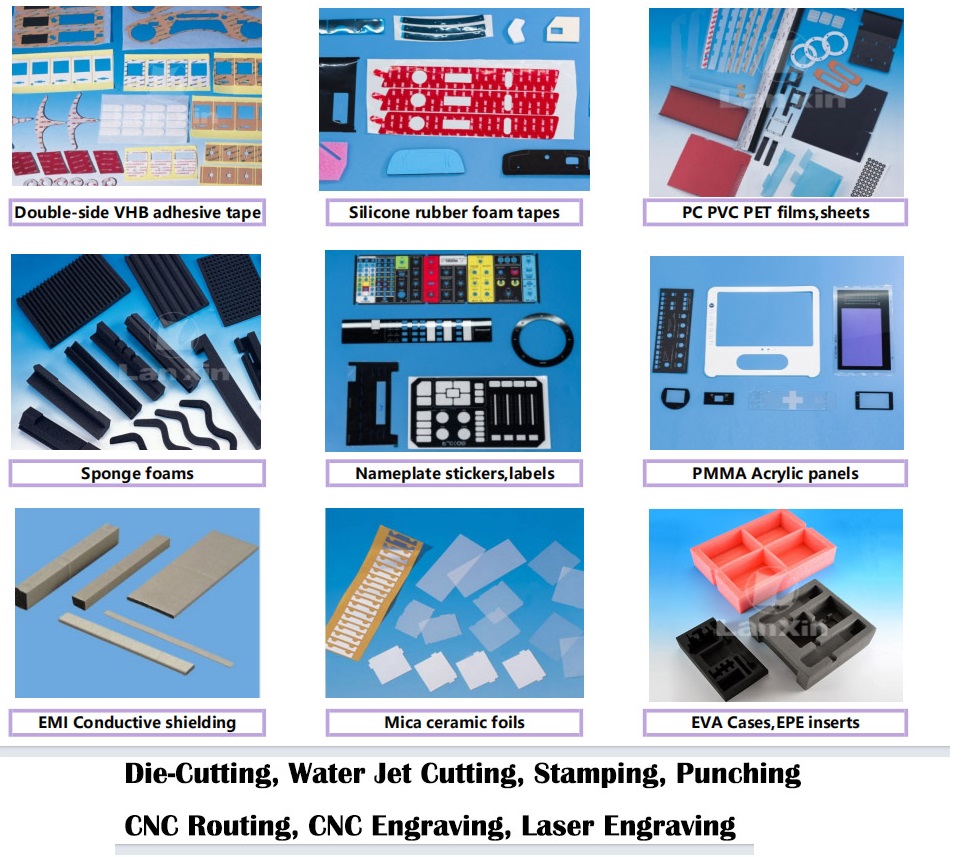

| Material | Die-Cutting materials can improve efficiency and output quality. Here are just a few of the materials that we can die-cut:

|

| Certificate | IATF 16949:2016 / ISO 9001:2015 / ISO 45001:2018 / ISO 14001:2015 /REACH/ROHS/MSDS/LFGB/F D A |

| Drawing Format | .stp / .step / .igs /.stl /.dwg / .pdf |

| Cutting types | Rotary die-cutting, flatbed die-cutting, waterjet cutting, CNC, etc... |

3M, Nitto, and Tesa are leading names in the adhesive tape industry. 3M offers versatile products like 3M 467MP, a double-sided transfer tape without a carrier, which is highly adhesive and suitable for bonding smooth surfaces in electronics and general assembly. Nitto's No.5000NS is a well-known double-sided tape, praised for its strong initial adhesion and good solvent resistance, commonly used in automotive interior bonding and consumer electronics. Tesa's 4982 is a high-performance double-sided PET tape, ideal for bonding plastics, metals, and other materials in industrial applications due to its excellent shear and peel strength.

Lanxin Company, as a long-term partner of 3M, Nitto, and Tesa, stands out in die-cutting adhesive tape production. Thanks to these partnerships, we can source a wide range of tape models with diverse performance features at favorable prices, enabling us to provide cost-effective solutions to our customers. What's more, we maintain a large-scale inventory all year round, ensuring that we can promptly meet various customer needs, whether it's urgent orders or bulk requirements. Our deep understanding of these tapes, combined with advanced die-cutting technology, allows us to customize adhesive tapes precisely, delivering high-quality and efficient services tailored to different application scenarios.

This allows us to achieve an astonishing dimensional accuracy of up to ±0.01mm for our die-cut adhesive tape products, far surpassing industry average standards.

Our stringent quality control process plays a crucial role in precision assurance. Before production, our experienced engineers conduct in-depth simulations and analyses using professional CAD/CAM software, optimizing cutting paths and parameters to ensure the most accurate results. During the die-cutting process, real-time monitoring systems continuously track the cutting status, promptly adjusting any deviations to maintain precision. Each batch of products undergoes multi-level inspections. We use high-precision measuring instruments such as optical comparators and coordinate measuring machines (CMMs) to carefully measure key dimensions, adhesive thickness, and edge quality of the die - cutting adhesive tapes.

Furthermore, Lanxin's team of skilled technicians regularly calibrates and maintains our die-cutting equipment to ensure long-term stable and accurate operation. Whether it's producing adhesive tapes with complex shapes for micro-electronics or large-format tapes for industrial assembly, our strict precision control guarantees that every product can achieve a perfect fit in the intended application, enhancing overall product performance and reliability.

Images for reference

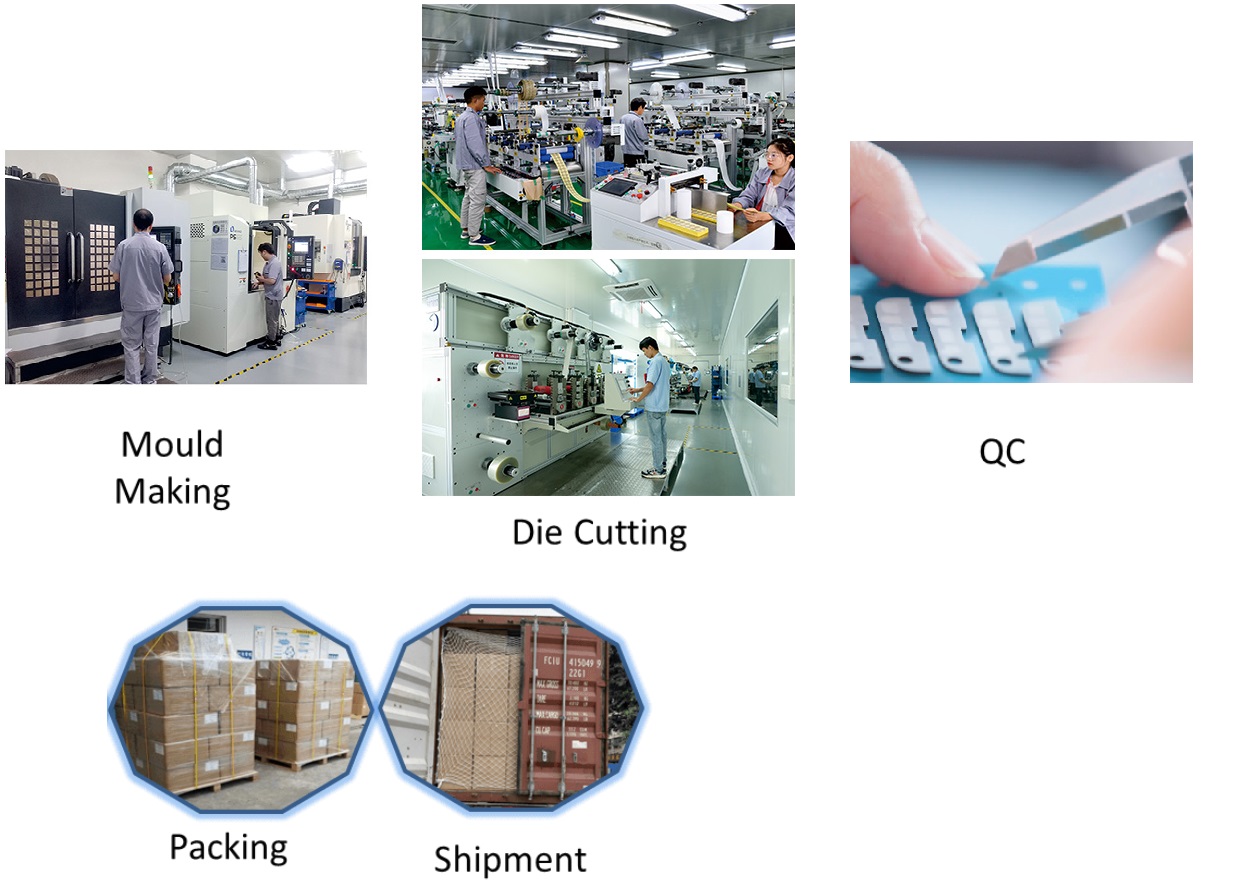

Producing Process

Quality standard

Lanxin's insulation materials quality is 100% according to ISO9001 Standard. We seriously take care of the quality control from IQC to OQC, throughout each step of the production.

Lanxin dedicated to strict quality control and thoughtful customer service. We strive to exceed our customers' expectation in all aspects of product manufacturing process, and recognize our great responsibilities to our customers.

FAQ

Q1: How soon can I get a precise quotation for custom die cutting insulated materials ?

A1: Please send us your inquiry by email or phone call. Once we confirm the design (Feature details with parameters), material, color, qty, we can provide quotation within 24 HOURS.

Q2: Can I get a free sample, how long will it take?

A2: a. For standard products we have in stock, YES for free sample, but the express fee will be charged in advance. Mostly, it takes 3-10 days.

b. For custom products, sample fee is determined by the detailed sample requirements. Normally, it takes 7-15 days.

Q3: Can you make custom parts based on my sample?

A3: Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing for production.