Liquid Silicone Rubber Injection Molding

Liquid silicone rubber molding enables large-scale manufacturing of silicone products. It can meet the needs of food-grade and medical-grade industries. Below are the steps for customizing silicone rubber products through the LSR molding process.

The LSR molding process is mainly divided into two parts: A (matrix) and B (catalyst). The two materials are injected directly into a sealed mold, where the materials combine and begin to vulcanize, or cure, into the precise part geometry. After the curing process is complete, the machine ejects the finished part.

We—Lanxin Over 20 years’s experience Custom Silicone Products Manufacturer

Our workshop has more than 20 liquid silicone molding machines to provide mass production services and shorten the production cycle. Support 2k injection molding.

We have professional cleanrooms and are ISO13485 certified. Provide a strictly hygienic production environment for medical devices and precision electronic components. Mainly providing LSR injection molding and over-molding services. The specialty goods of us include precision parts, seals, optical lenses, etc.

Advantages of LSR injection molding:

*Reduced cycle time

*Flashless tooling

*Economical process for high volumes of medium to high precision components

*Capable of producing overmolded components

*Minimal material waste

Characteristics Of Silicone

Silicone raw materials offer a range of advantages across various industries due to their unique properties and versatility. Some of the key advantages include:

1. Heat Resistance

Silicone materials can withstand high temperatures, typically ranging from -40°C to 230°C (-40°F to 446°F).

2. Flexibility and Elasticity

Silicone materials are highly flexible and elastic, allowing them to maintain their shape and properties over a wide range of temperatures and environmental conditions. This makes them suitable for applications that require durability and resilience, such as in seals, gaskets, and medical implants.

3. Biocompatibility

Silicone materials are biocompatible and are widely used in medical devices and implants, such as catheters, prosthetic devices, and breast implants.

4. Non-Toxicity

Silicones are generally non-toxic and inert, making them safe for use in food-contact applications such as cookware, baking molds, and kitchen utensils.

5. Transparency

Some silicone materials are transparent, allowing for optical applications such as lenses, optical fibers, and LED encapsulants.

6. Electrical Insulation

Silicone rubber has excellent electrical insulation properties, making it suitable for use in electrical and electronic components such as insulators, gaskets, and seals.

7. Chemical Resistance

Silicone raw materials offer versatility and value in numerous industries including automotive, medical, electronics, industrial fields, and more.

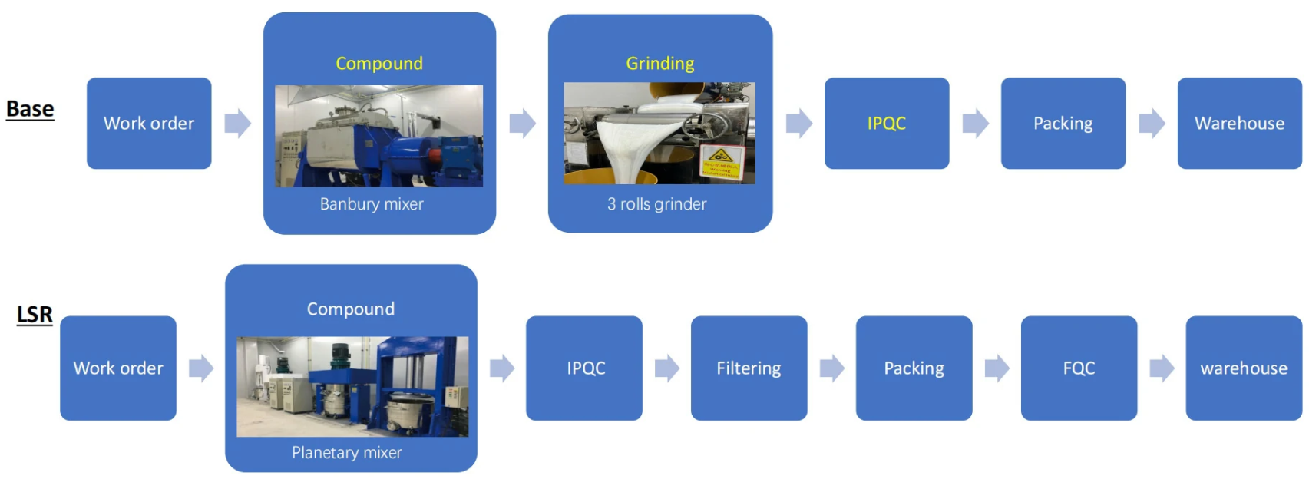

Production Process

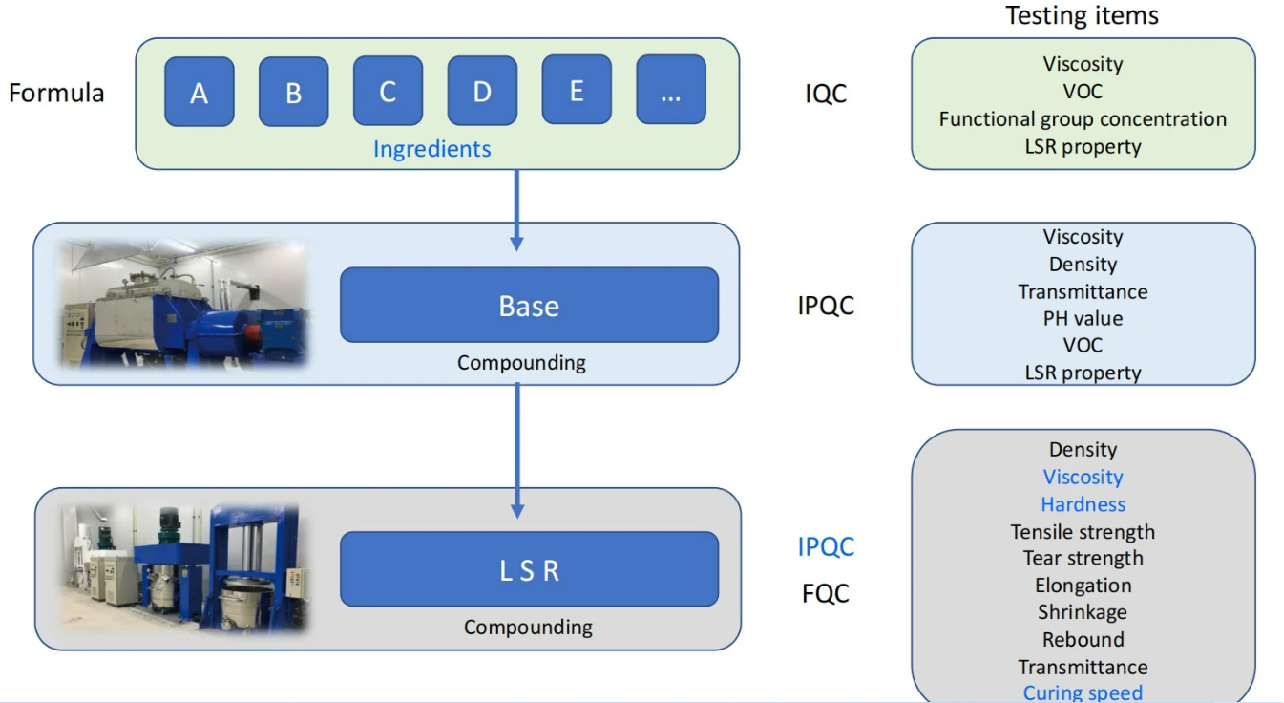

Quality Control

100% inspection for order,we seriously take care of the quality control from IQC to OQC, throughout each step of the production. Let us show you our quality control:

For raw materials, we’ll do the IQC in time. All materials are procured only from the verified suppliers, who have implemented and maintain certified quality management systems in their plants. With full certificates, such as RoHs, Reach, MSDS, FDA, LFGB, UL, EN549, BPA free, EN71, and so on;For pre-production samples, we'll provide several pieces to our clients for assembly and function testing.

Inspection instrument