We offer CNC Machining Solutions to meet your brand's specific goals and requirements. Our facilities are equipped with the latest technology to enable us to achieve the best results. As the leading CNC machining parts manufacturers, Lanxin company are sure to meet and exceed your expectations. If you are not sure where to start, please contact us for a free consultation.

Support ODM/OEM to meet customer's individual needs

We have our factory with years of sales and production experience

Adopt green environmental protection international brands material.Health and safety

We provide high quality customer service, please consult Lanxin cnc machining

1. High precision and high accuracy

Lanxin's advanced CNC equipment can achieve strict tolerance control of ±0.001 inches, meeting the stringent requirements of aerospace, medical equipment and other fields. Accurate conversion from design to processing instructions ensures stable product quality and avoids most of routine errors.

2. Excellent consistency and repeatability

In large-scale production, the company's CNC machining technology can stably produce parts that fully meet specifications, greatly reduce the defective rate, and provide high-quality parts for high precision industries.

3. Efficient and fast processing

Supporting multi-axis equipment can perform multiple operations at the same time, shorten delivery cycles, optimize production processes, and respond quickly to customer needs.

4. Rich material adaptability and diversified processing technology

Whether it is metal, plastic or composite materials, the company can process efficiently, and the equipment can complete multiple processes such as drilling and cnc milling under the same setting, providing a one-stop processing solution.

5. Significantly reduce material waste

Through precise programming to optimize the cutting path and reduce material waste, it not only controls costs but also conforms to the concept of environmental protection.

6. Excellent operator safety

Highly automated equipment reduces direct contact between personnel and equipment, and features such as automatic tool change and software update reduce safety hazards and ensure employee safety.

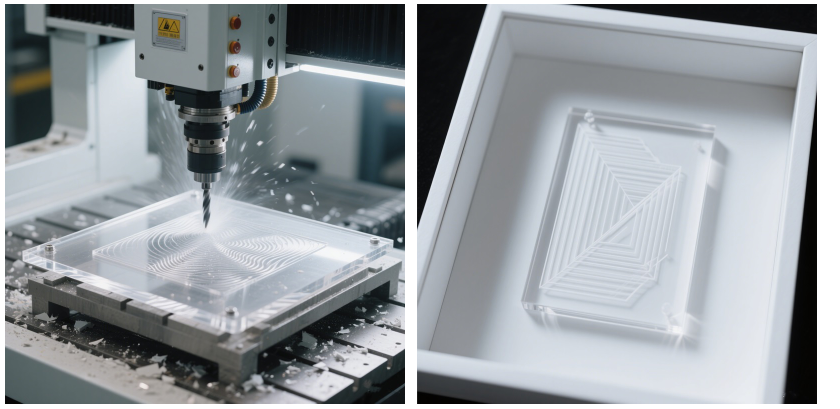

What is CNC Milling and How Does it Work?

CNC milling is a subtractive manufacturing process. It starts by fixturing a block of metal or plastic material inside the CNC mill. Using G-code, the CNC machine is programmed to rapidly mill out parts from the block of raw material. Our 3- and 5-axis CNC machines are equipped with various toolsets to maximize efficiency and production speed.

Machined plastic parts are left as-milled, which typically means they show visible tool marks. Some metal parts allow more finishing choices like anodizing and chromate plating.

CNC Milling Materials

We stock more than 30 production-grade plastic and metal materials that are suitable for various part applications and industries.

Plastics;

ABS PVC HDPE LDPE Nylon PEEK PEI PET

PMMA-Acrylic PC-Polycarbonate Polypropylene

POM-Delrin PPSU HIPS PSU PTFE