We offer CNC Machining Solutions to meet your brand's specific goals and requirements. Our facilities are equipped with the latest technology to enable us to achieve the best results. As the leading CNC machining parts manufacturers, Lanxin company are sure to meet and exceed your expectations. If you are not sure where to start, please contact us for a free consultation.

Support ODM/OEM to meet customer's individual needs

We have our factory with years of sales and production experience

Adopt green environmental protection international brands material.Health and safety

We provide high quality customer service, please consult Lanxin cnc machining

CNC Routing is a specific process within CNC machining (Computer Numerical Control Machining). It primarily involves using pre-programmed computer software to control a rotating cutting tool (such as an end mill or engraving bit) for precise cutting, engraving, milling, or shaping of materials. This technique is widely used for 2D or simple 3D planar processing, removing excess material from the surface to create detailed patterns, shapes, or structures.

Core Characteristics

Working Principle

Utilizes a rotating tool to cut materials layer by layer. It mainly operates along the X and Y axes (with limited Z-axis linkage for some machines), making it suitable for flat or slightly curved surfaces (distinct from complex multi-axis milling).

The tool’s movement and speed are controlled by numerical codes (G-code), ensuring high precision in each operation.

Suitable Materials

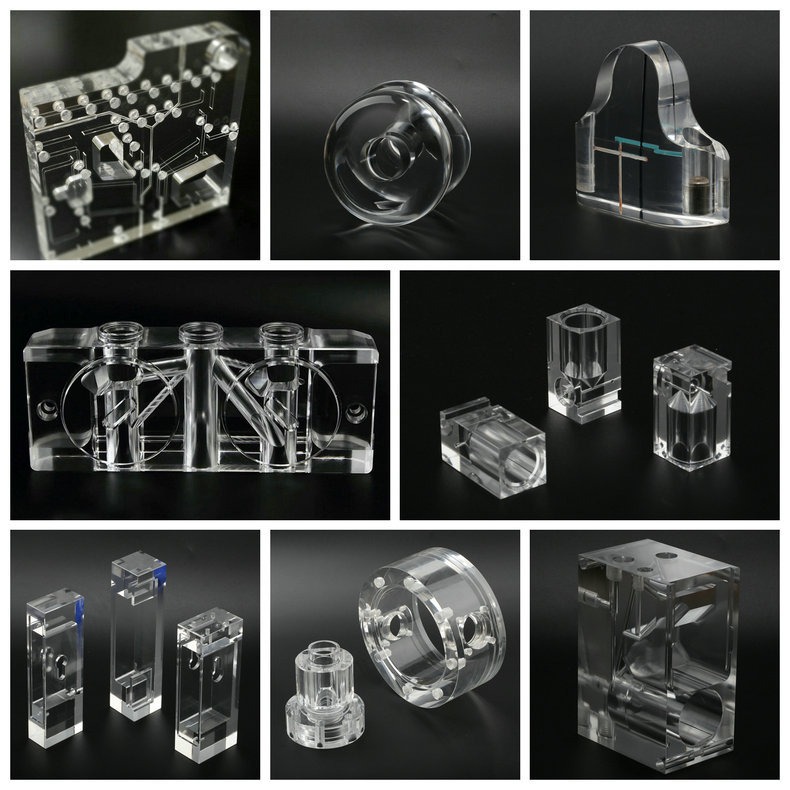

Primarily used for non-metallic or soft metallic materials, including:Wood (furniture panels, crafts), plastics (acrylic, PVC), foam (model making), composites (fiberglass, carbon fiber boards), and soft metals (aluminum, copper).

Less ideal for hard metals (e.g., steel), which are better suited for CNC milling or lathe processing.

Typical Applications

Advertising industry: Cutting acrylic signs, display boards, and lettering.

Woodworking & furniture: Engraving decorative patterns, cutting custom cabinet components, or shaping wooden parts.

Prototyping & modeling: Fabricating architectural models, industrial design prototypes (e.g., foam/plastic models).

Art & crafts: Creating relief carvings, personalized gifts, or decorative items.

Electronics & aerospace: Machining lightweight components (e.g., circuit board trays, composite parts).

Differences from CNC Milling

| ITEM | CNC Routing | CNC Milling |

| Material | Focuses on non-metals or soft metals. | Handles hard metals (steel, titanium) and rigid materials. |

| Axes | Mostly 2-axis (X/Y) or 2.5-axis (limited X/Y/Z linkage). | Typically 3-axis or multi-axis (4/5-axis) for complex 3D surfaces. |

| Tool Type | Uses small engraving bits or flat-end mills. | Employs larger milling cutters or drills for heavy-duty cutting. |

| Cutting Depth | Suitable for shallow or planar cuts. | Capable of deep cavities, through-holes, and intricate 3D structures. |

CNC Routing Materials

We stock more than 30 production-grade plastic and metal materials that are suitable for various part applications and industries.

Plastics;

ABS PVC HDPE LDPE Nylon PEEK PEI PET

PMMA-Acrylic PC-Polycarbonate Polypropylene

POM-Delrin PPSU HIPS PSU PTFE

CNC Routing Advantages

High Precision & ConsistencyAchieves minimal error (usually within ±0.1mm) through program control, ideal for mass-producing identical parts.

Flexible CustomizationEasily adapts to design changes via CAD/CAM software (e.g., AutoCAD, VCarve) without physical mold adjustments, making it cost-effective for small-batch or custom projects.

Efficiency & Cost-EffectivenessReduces manual labor through automation and optimizes material usage, appealing to SMEs and creative industries.

Common Equipment & Software

Machines: Desktop CNC engravers, industrial CNC Router systems (often equipped with vacuum tables for material fixation).