Product Description

Plastic structural parts are essential components in many products across industries, providing mechanical support and maintaining structural integrity. These parts can be made in complex, high-precision shapes. A variety of plastic materials are used, allowing customization of mechanical and chemical properties like strength, heat resistance, or chemical inertness. They are lightweight, cost-effective for large-scale production, and can be customized in color and surface finish. Plastic materials for these parts are selected based on mechanical properties. Common engineering plastics include polycarbonate (PC), polyamide (PA or nylon), and polyphenylene sulfide (PPS). PC offers high impact resistance, good dimensional stability, and sometimes optical clarity, suitable for applications like automotive headlamp lenses.

Applications

Injection mold plastic parts are applied in various industries. In electronics, they are used for enclosures, connectors, and small components. The automotive industry utilizes them for interior and exterior trim, as well as engine parts. In the consumer goods sector, items like toys and kitchen utensils often feature injection - molded plastic parts due to their versatility and cost - effectiveness. Functionally, it serves as a protective barrier against dust, moisture, and physical harm. Its design is often customized to fit specific devices precisely, providing a snug fit. In addition to protection, some housing plastic covers are designed with aesthetic appeal in mind, enhancing the overall look of the device. Manufacturers adhere to strict quality control processes.

| ITEM | Molding injection plastic shell |

| Material | PP, PC, POM, PPS, ABS, PMMA, PLA, PBT, PE, PEEK, etc... |

| Certificate | IATF 16949:2016 / ISO 9001:2015 / ISO 45001:2018 / ISO 14001:2015 /REACH/ROHS/MSDS/LFGB/F D A |

| Drawing Format | .stp / .step / .igs /.stl /.dwg / .pdf |

| Function | Industrial parts /daily supply / Automotive/ Medical device, etc... |

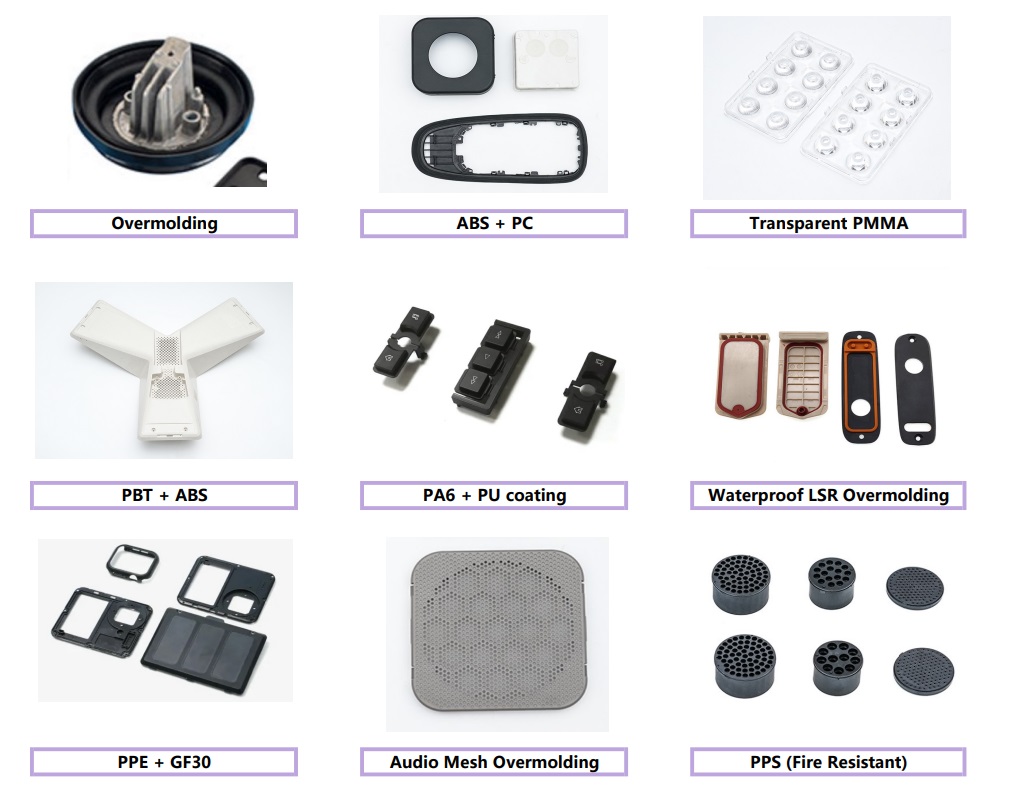

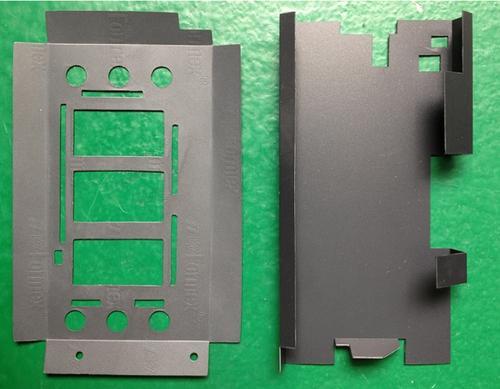

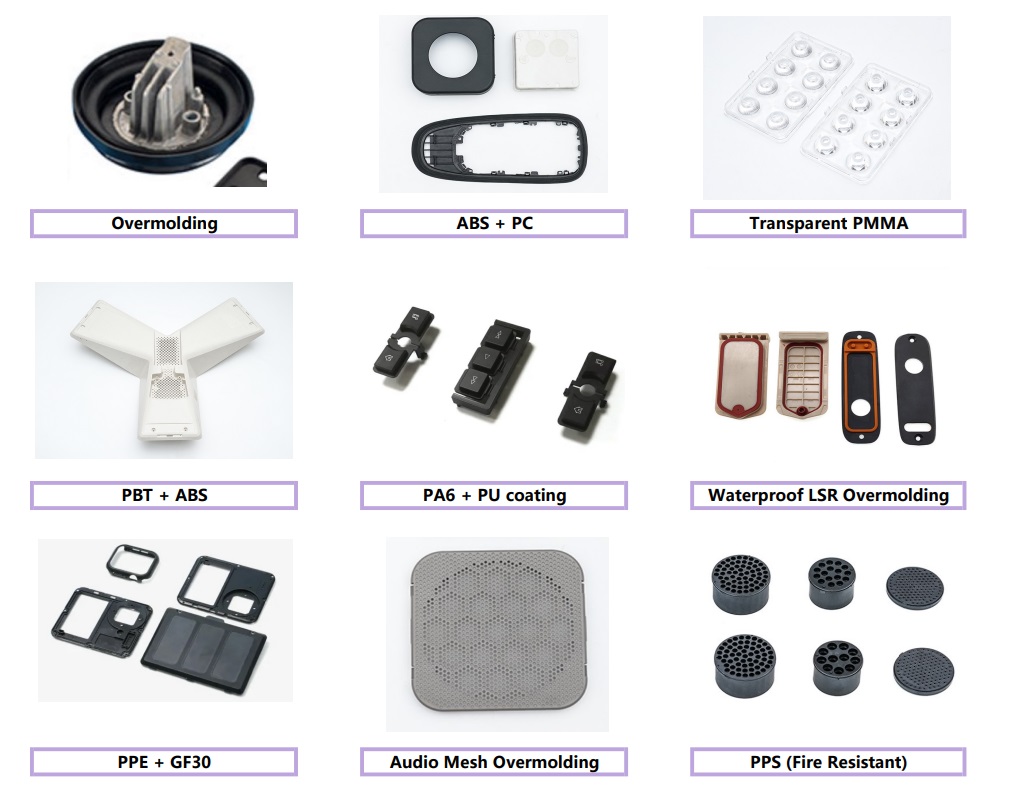

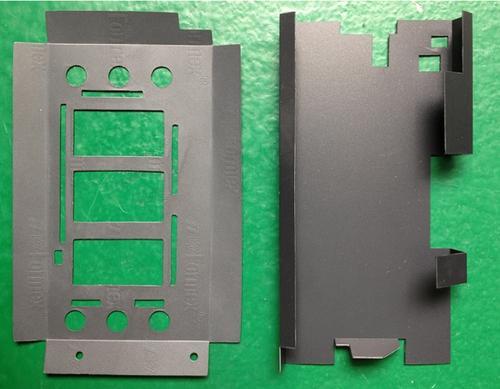

Images for reference

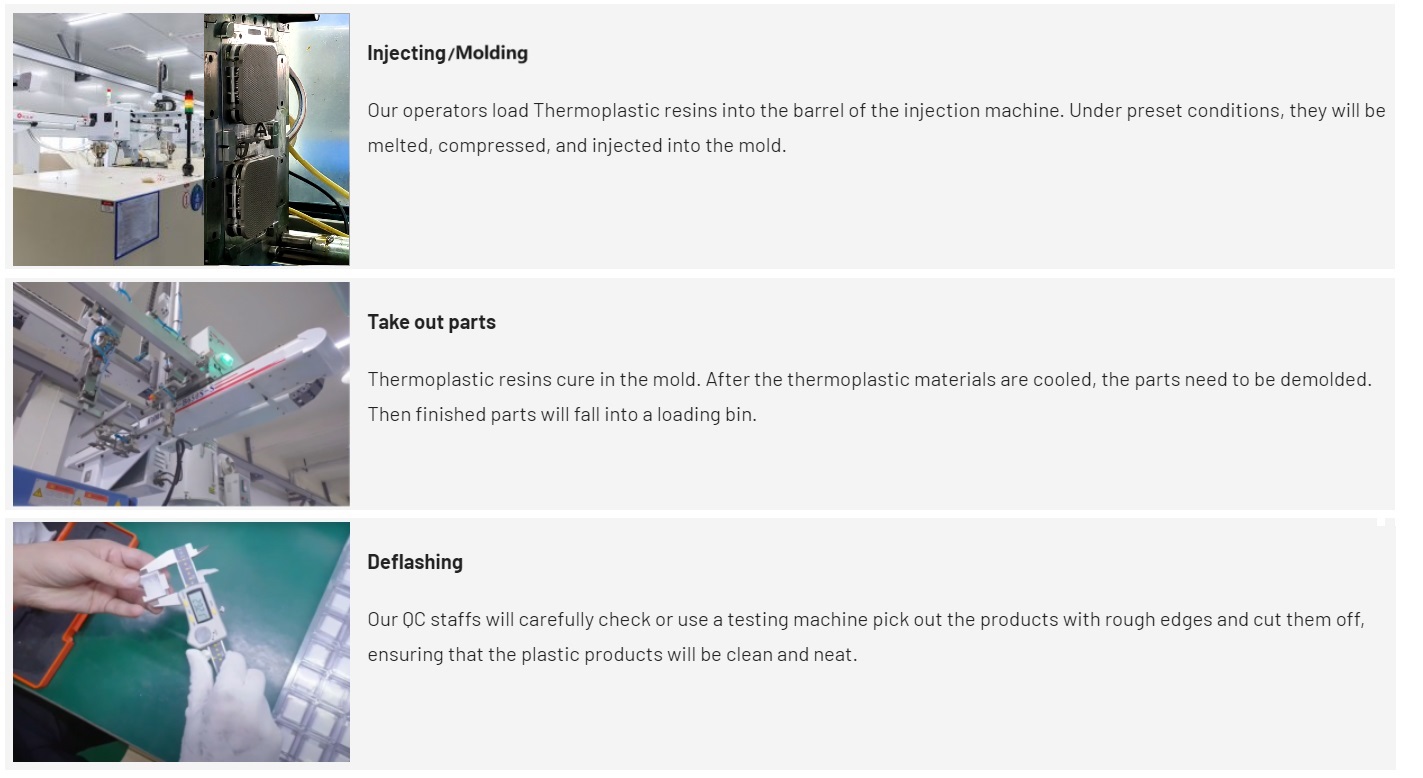

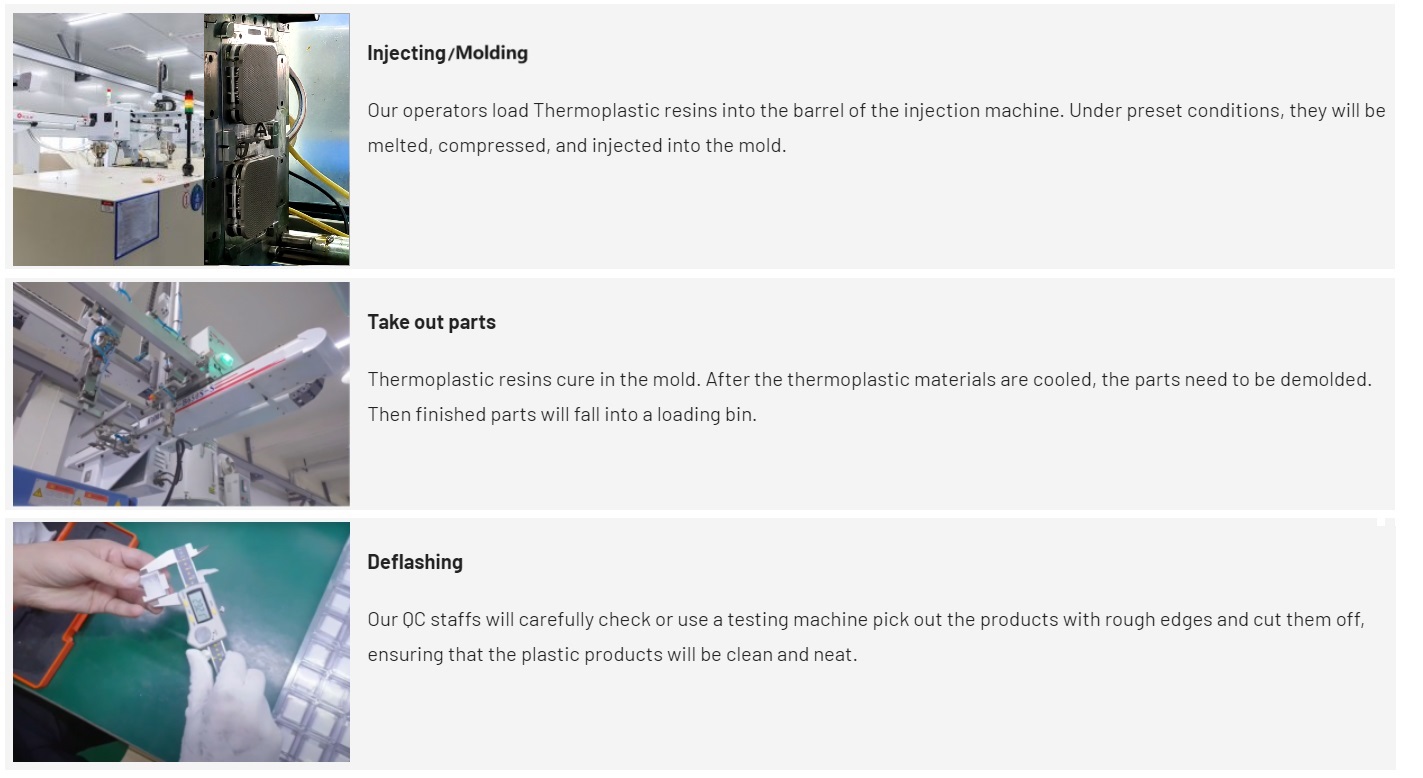

Producing Process

Quality Standard

From the selection of raw materials to the final product inspection, every step is carefully monitored. This includes checks for proper molding, thickness consistency, and color fastness. With such quality assurance, customers can rely on the housing plastic cover to effectively protect their valuable devices.

Sample Selection: If a sampling plan is in place, select the samples according to the plan. Ensure that the samples are representative of the entire batch or lot.

Measurement and Testing: Conduct the planned measurements, tests, and examinations on the samples. For example, measure the dimensions of a product using the selected measuring tools, perform functional tests to check if the product operates correctly, and visually inspect for any signs of damage, defects, or non - compliance.

Data Recording: Record all the inspection data accurately. This includes the measured values, the results of the tests, and any observations made during the inspection. Use a standardized format for recording to ensure consistency and ease of analysis.

Defect Identification: If any defects or non - conformities are found, clearly identify and document them. Classify the defects as critical, major, or minor based on their impact on the product's functionality, safety, or compliance with standards.

Comparison with Standards: Compare the inspection results with the pre - defined acceptance criteria. Determine whether each quality characteristic of the product or service meets the specified standards.

Decision - Making: Based on the comparison, make a decision on whether the product or service is acceptable. If the product meets all the acceptance criteria, it can be considered passed. If there are defects, decide whether the product can be reworked, requires further inspection, or should be rejected.

Documentation of Results: Document the final inspection results, including the decision made. Include details of any defects found, the actions taken (such as rework or rejection), and the signatures of the inspectors.

FAQ

Q1: How soon can I get a precise quotation for custom injection molding plastic parts ?

A1: Please send us your inquiry by email or phone call. Once we confirm the design (Feature details with parameters), material, color, qty, we can provide quotation within 24 HOURS.

Q2: Can I get a free sample, how long will it take?

A2: a. For standard products we have in stock, YES for free sample, but the express fee will be charged in advance. Mostly, it takes 3-10 days.

b. For custom products, sample fee is determined by the detailed sample requirements. Normally, it takes 7-15 days.

Q3: Can you make custom parts based on my sample?

A3: Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing for production.

Q4: What does your OEM service include?

A4: We follow up your request from the design idea to the bulk production.

a. You can provide 3D drawing to us, then our engineers and production teams evaluate the design and quote you the precise cost.

b. If you don’t have 3D drawing, you can provide 2D drawing or draft with features details with full dimensions, we can draft 3D drawing for you with fair charge.

c. You can also customize Logo on the product surface, package, color box or carton.

d. We also provide assembly service for the OEM parts.

Q5. What is your payment term?

A5: We accept T/T, Paypal, Western Union, L/C, Alibaba Trade Assurance.