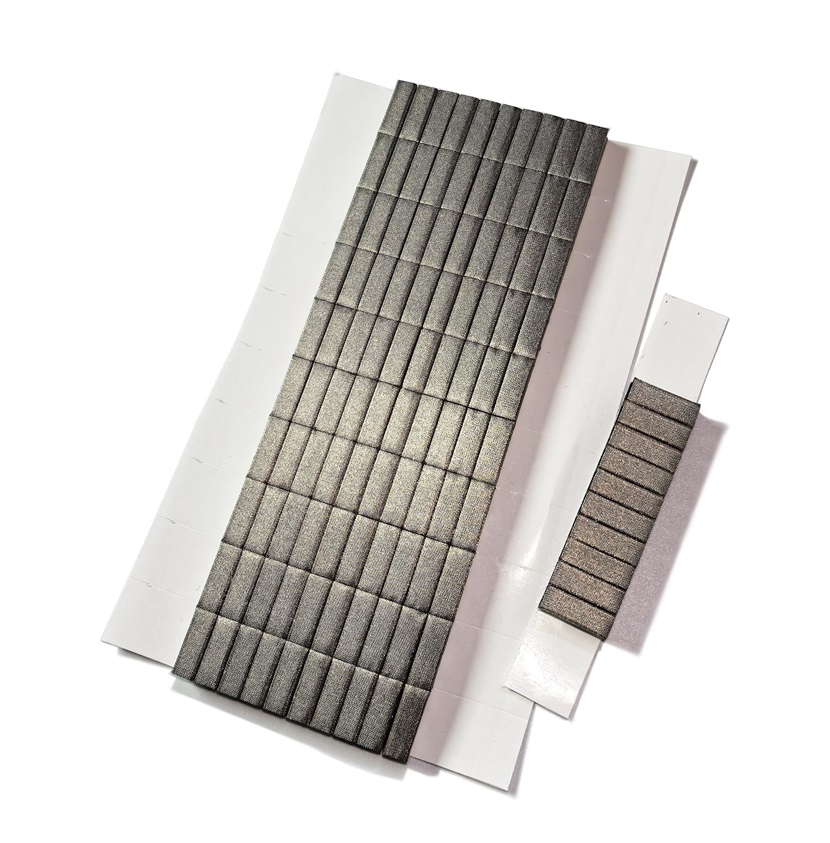

Product Description

| ITEM | EMI foam, EMI shielding gasket |

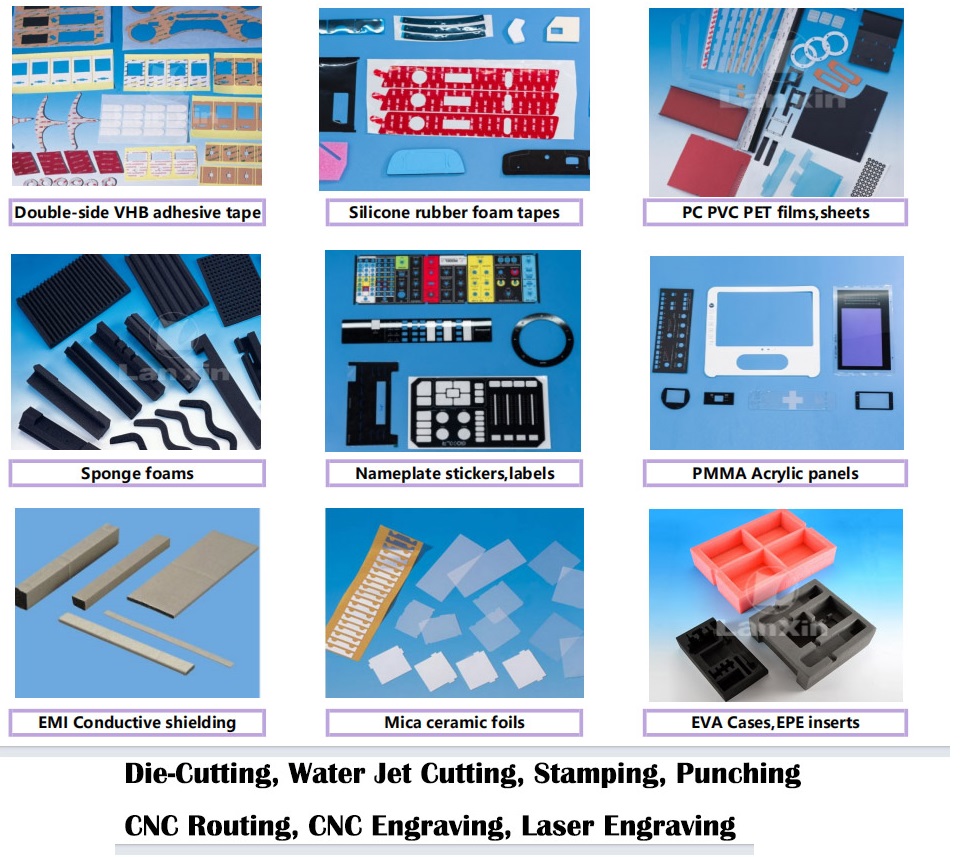

| Material | Die-Cutting materials can improve efficiency and output quality. Here are just a few of the materials that we can die-cut:

|

| Certificate | IATF 16949:2016 / ISO 9001:2015 / ISO 45001:2018 / ISO 14001:2015 /REACH/ROHS/MSDS/LFGB/ FDA |

| Drawing Format | .stp / .step / .igs /.stl /.dwg / .pdf |

| Cutting types | Rotary die-cutting, flatbed die-cutting, waterjet cutting, CNC, etc... |

EMI foam is a high-performance, flexible shielding material engineered to block electromagnetic interference (EMI) and radio frequency interference (RFI). Blending conductive metals (such as copper, nickel, or silver) with resilient foam substrates like polyurethane or silicone, it delivers superior shielding effectiveness while offering excellent compression recovery and conformability.

This foam creates a reliable conductive barrier that safeguards sensitive components from external interference and prevents internal signal leakage. Its lightweight design, corrosion resistance, and easy installation make it a go-to solution for compact, high-tech applications where both shielding performance and space efficiency matter.

Images Reference

Related Products

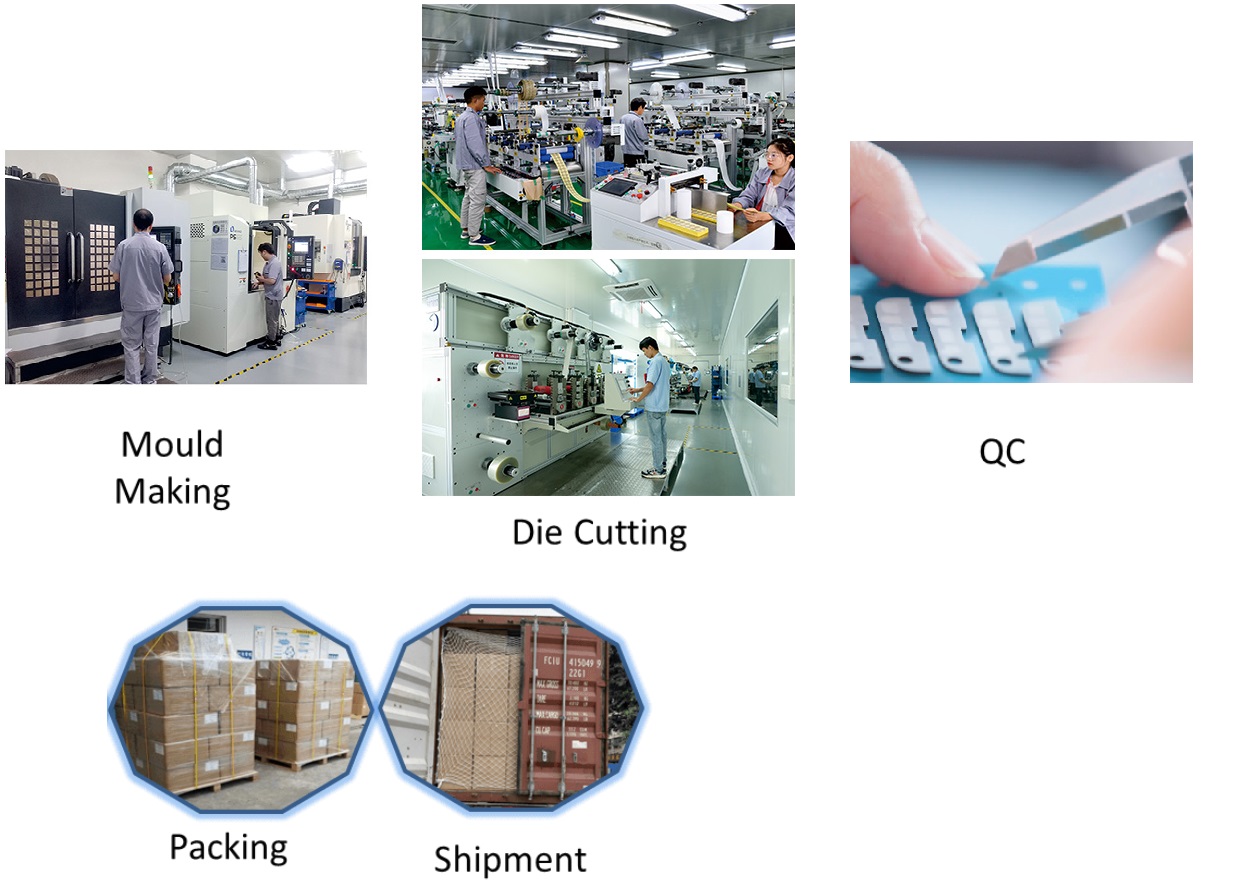

Producing Process

Quality Standard

Lanxin's insulation materials quality is 100% according to ISO9001 Standard. We seriously take care of the quality control from IQC to OQC, throughout each step of the production.

FAQ

Q1: How soon can I get a precise quotation for custom die cutting insulated materials ?

A1: Please send us your inquiry by email or phone call. Once we confirm the design (Feature details with parameters), material, color, qty, we can provide quotation within 24 HOURS.

Q2: Can I get a free sample, how long will it take?

A2: a. For standard products we have in stock, YES for free sample, but the express fee will be charged in advance. Mostly, it takes 3-10 days.

b. For custom products, sample fee is determined by the detailed sample requirements. Normally, it takes 7-15 days.

Q3: Can you make custom parts based on my sample?

A3: Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing for production.