Die Cutting, Stamping

Die-cut products are made from sheet non-metal and light metal materials through die-cutting and stamping.

It offers precision, process flexibility, low cost set up, and is ideally suited for both low and high volume production. As experts in the manufacturing of parts composed of rubber compounds. Die cut gaskets can be supplied plain or pre-laminated with pressure sensitive adhesives; we have an extensive range of adhesives to suit numerous applications, our sales team are on hand to help you with your requirements.

The die-cutting mould cost is cheap, but the material is purchased from rubber sheet, this kind of material perfermance (such as temperature resistant, resists deformation, compression set, tensile strength etc.. ) is not as good as compression parts.

Common Materials

Foam: EPDM, rubber, eva, epe, sponge, cr

Foam pad: poron, eva, silicone, silicone foam, rubber

Adhesive tape: 3M, Nitto, Tesa, Sony, PE foam

Film: PP, PET, PC, PVC, FR, Mica,PMMA, TPU

Shielding: EMI foam, FIBER, Aluminum foil, Copper foil, Fabric

The above are the materials commonly used in the electronics and equipment manufacturing industry.

If you want to know more details, please click here and we will serve you wholeheartedly.

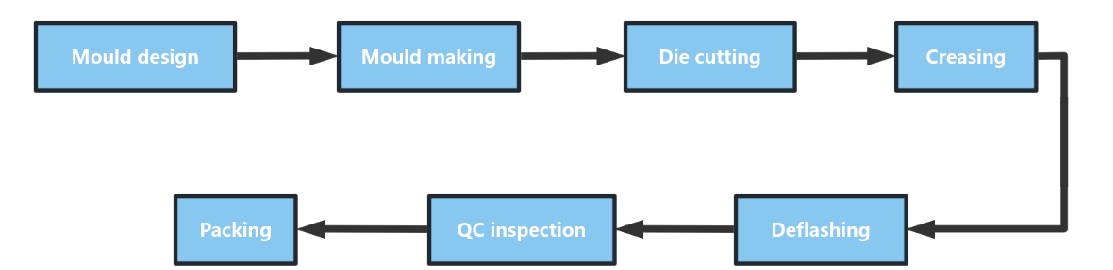

Production Process

Our Advantage

Lanxin Industrial can provide you with different kinds of materials for your specific industrial application. We can offer you a very competitive price for the product and low MOQ. As ISO 9001:2015 and ISO 14001:2015 certified, you can trust the quality and commitment behind our products.

Quality Control

The materials we use are extremely strict. We will conduct strict screening from the source suppliers. The selected suppliers must be ISO certified first. The purchased materials are required to provide certification information and test reports. Our IQC will conduct a series of inspections from the time the materials are put into storage to before production.

For raw materials, we’ll do the IQC in time. All materials are procured only from the verified suppliers, who have implemented and maintain certified quality management systems in their plants. With full certificates, such as RoHs, Reach, MSDS, FDA, LFGB, UL, EN549, BPA free, EN71, and so on;

For pre-production samples, we'll provide several pieces to our clients for assembly and function testing. We will seal the samples in time once they're approval.

For Bulk Production, we'll do the IPQCS & PQC (Multiple Sampling Inspection) during production and we'll do the FQC (Sampling Inspection) after deburr or breaking sharp edges. In order to timely find problems, solve problems, reduce defective products, reduce manufacturing costs.

After packing and assembling, we'll do the OQC (Sampling Inspection) to make sure the final goods are qualified.

Workshop and equipments

2.5D measuring instrument

2.5D measuring instrument

Three-dimensional (3D) detector

Micrometer Hardness tester

Starrett image measuring instrument

XRF spectroscopy test machine .......