Screen Printing

Screen printing refers to the use of a silk screen as a base plate and a photosensitive plate-making method. The basic principle is that the mesh holes of the graphic part of the screen printing plate can pass ink, while the mesh holes of the non-graphic part cannot pass ink, thus making a silk screen printing plate with graphics.

Advantages:

1. Strong applicability and diverse materials, whether it is plastic or glass or metal, it can be screen printed.

2. Low cost, no need to make a mould.

3. Flat objects or single curved surfaces are basically barrier-free.

Disadvantages:

1. Only single color can be printed, and the cost of printing two or more colors will be much more expensive (it is better to consider pad printing) .

2. Only single curved surface or flat surface can be printed, and complex curved surfaces cannot be printed.

3. Due to the need for manual operation, its production efficiency is not high.

Lanxin's silk screen printing processing is generally carried out directly on the surface of the product required by the customer, such as adding color and brand logo to the product. It is widely used in labels and film materials.

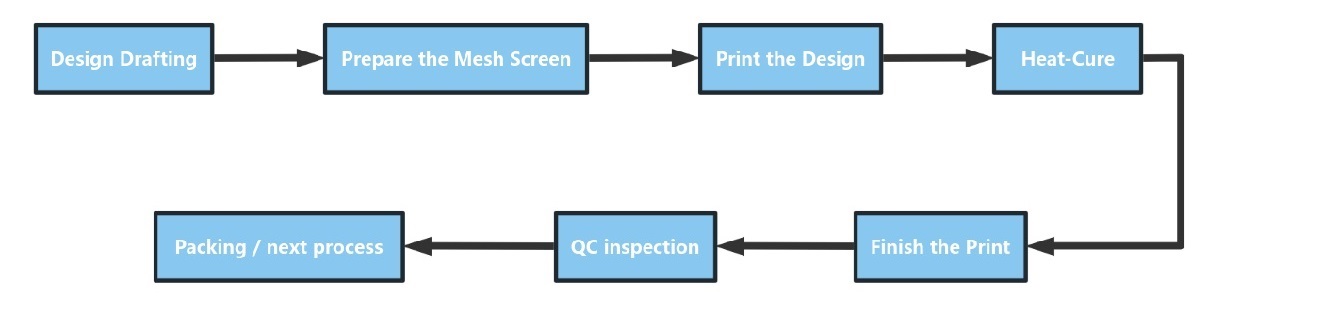

Production Process

Our Advantage

Lanxin Industrial can provide you with different kinds of materials for your specific industrial application. We can offer you a very competitive price for the product and low MOQ. As ISO 9001:2015 and ISO 14001:2015 certified, you can trust the quality and commitment behind our products.

Quality Control

The materials we use are extremely strict. We will conduct strict screening from the source suppliers. The selected suppliers must be ISO certified first. The purchased materials are required to provide certification information and test reports. Our IQC will conduct a series of inspections from the time the materials are put into storage to before production.

For raw materials, we’ll do the IQC in time. All materials are procured only from the verified suppliers, who have implemented and maintain certified quality management systems in their plants. With full certificates, such as RoHs, Reach, MSDS, FDA, LFGB, UL, EN549, BPA free, EN71, and so on;

For pre-production samples, we'll provide several pieces to our clients for assembly and function testing. We will seal the samples in time once they're approval.

For Bulk Production, we'll do the IPQCS & PQC (Multiple Sampling Inspection) during production and we'll do the FQC (Sampling Inspection) after deburr or breaking sharp edges. In order to timely find problems, solve problems, reduce defective products, reduce manufacturing costs.

After packing and assembling, we'll do the OQC (Sampling Inspection) to make sure the final goods are qualified.

Workshop and equipments