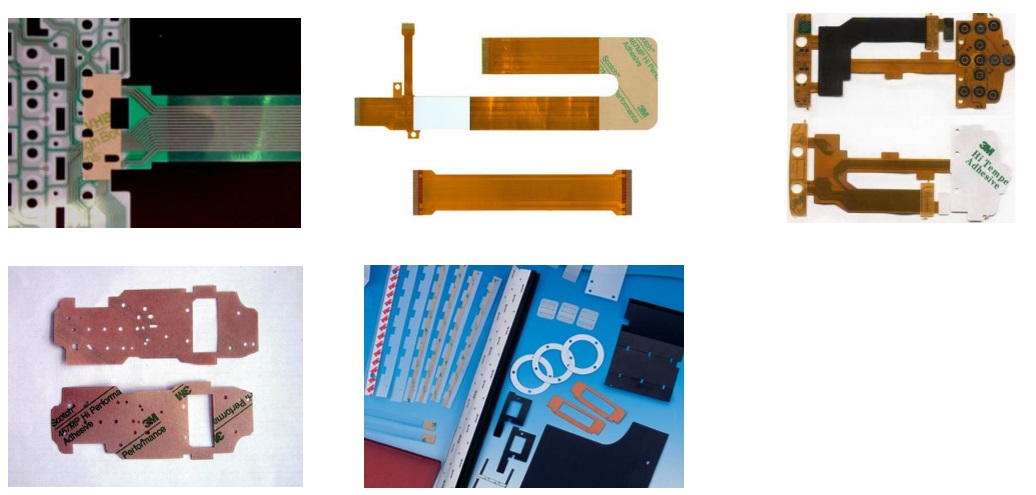

Adhesive products can be formed by stamping alone and are usually processed together with other electronic auxiliary materials. We take industrial tapes as an example. The following are common models:

Adhesive tape series

| Brand | Types | Thickness(mm) |

| 3M | 467 468 9448A 9448B 93010 93010LE 9495MP 9495LE 4914-25 | 0.08-0.17 |

| 3M | 4941 VHB 4950 VHB GPH-060GF VHB 5906 VHB 5952 VHB | 0.15-1.14 |

| nitto | T3820 J0900 J1370 5050 5000NS 500 white 500 black 5015 | 0.12-0.16 |

| TESA | 4965PV4 68644 4972 PV20 4982PV42 4980 20 4965PV4 | 0.11-0.67 |

| Sony | T4000 T4000B G4000 G9900 G9000SY UT1440 | 0.07-0.15 |

Here are some of the commonly used tapes in industry. Generally, customers need to understand the surface and environment to be affected and choose the appropriate tape based on the above conditions. The performance of tapes of different brands and models varies greatly. Generally speaking, European and American brand tapes have stronger adhesion, while Japanese brand tapes have low VOC.

Lanxin will select brand tapes based on the drawings provided by customers, or recommend the best bonding solution to customers with our more than 25 years of experience. At the same time, we have our own slitting and coating workshops to produce our own brand of high-performance tapes.