Product description

Many of the die-cutting materials we work with are already used in a variety of industries:

| ITEM | EVA foam gasket, Eva seals | ||

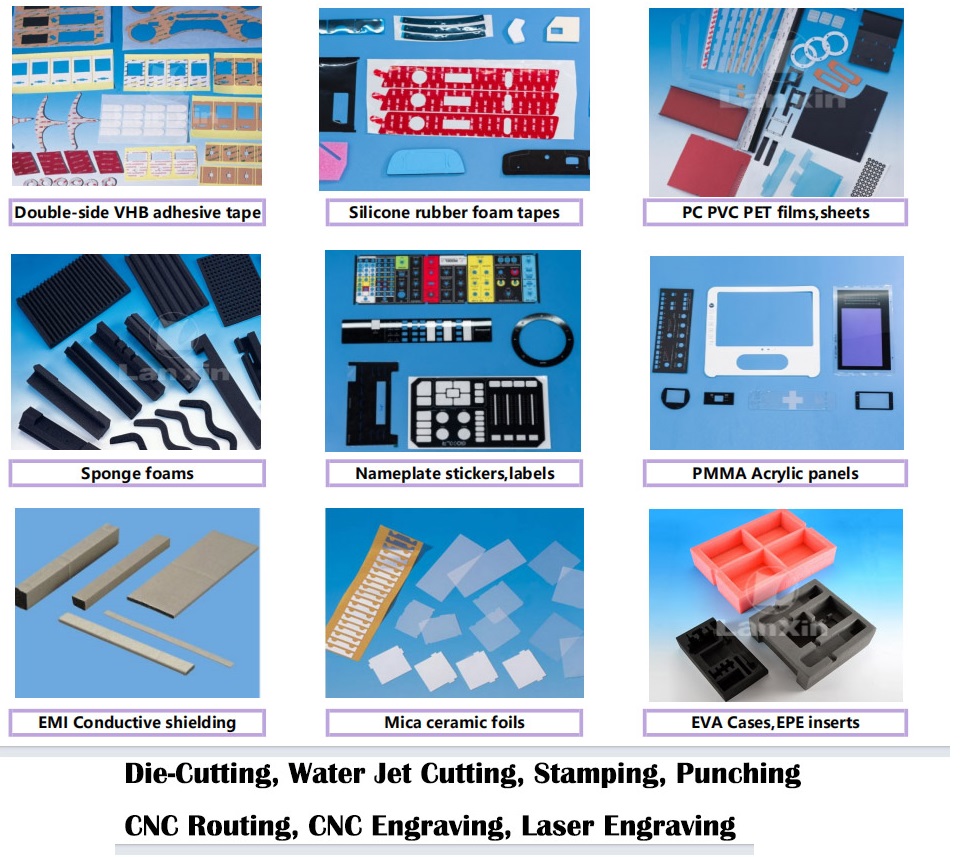

| Material | Die-Cutting materials can improve efficiency and output quality. Here are just a few of the materials that we can die-cut:

|

| Certificate | IATF 16949:2016 / ISO 9001:2015 / ISO 45001:2018 / ISO 14001:2015 /REACH/ROHS/MSDS/LFGB/F D A |

| Drawing Format | .stp / .step / .igs /.stl /.dwg / .pdf |

| Cutting types | Rotary die-cutting, flatbed die-cutting, waterjet cutting, CNC, etc... |

Features of EVA Foam Gasket

a) Impact and vibration absorption

b) Weather and chemical resistance including splash resistance to oils and fuels

c) Acoustic and thermal insulation properties

EVA foam gaskets, eva seals, and eva foam sealing products have become essential in various industries. These sealing solutions are highly valued for their versatility. In the construction industry, they are used for window and door frames, providing excellent weatherproofing by blocking out dust, water, and wind. In the electronics sector, EVA foam gaskets act as effective shock-absorbing buffers, protecting delicate components from vibrations and impacts during transportation and operation. For automotive interiors, eva seals ensure a tight fit, reducing noise, vibration, and harshness (NVH) levels to enhance the driving experience.

Lanxin Over 20 Years Experience EVA Seals Manufacturer In Guangdong, China

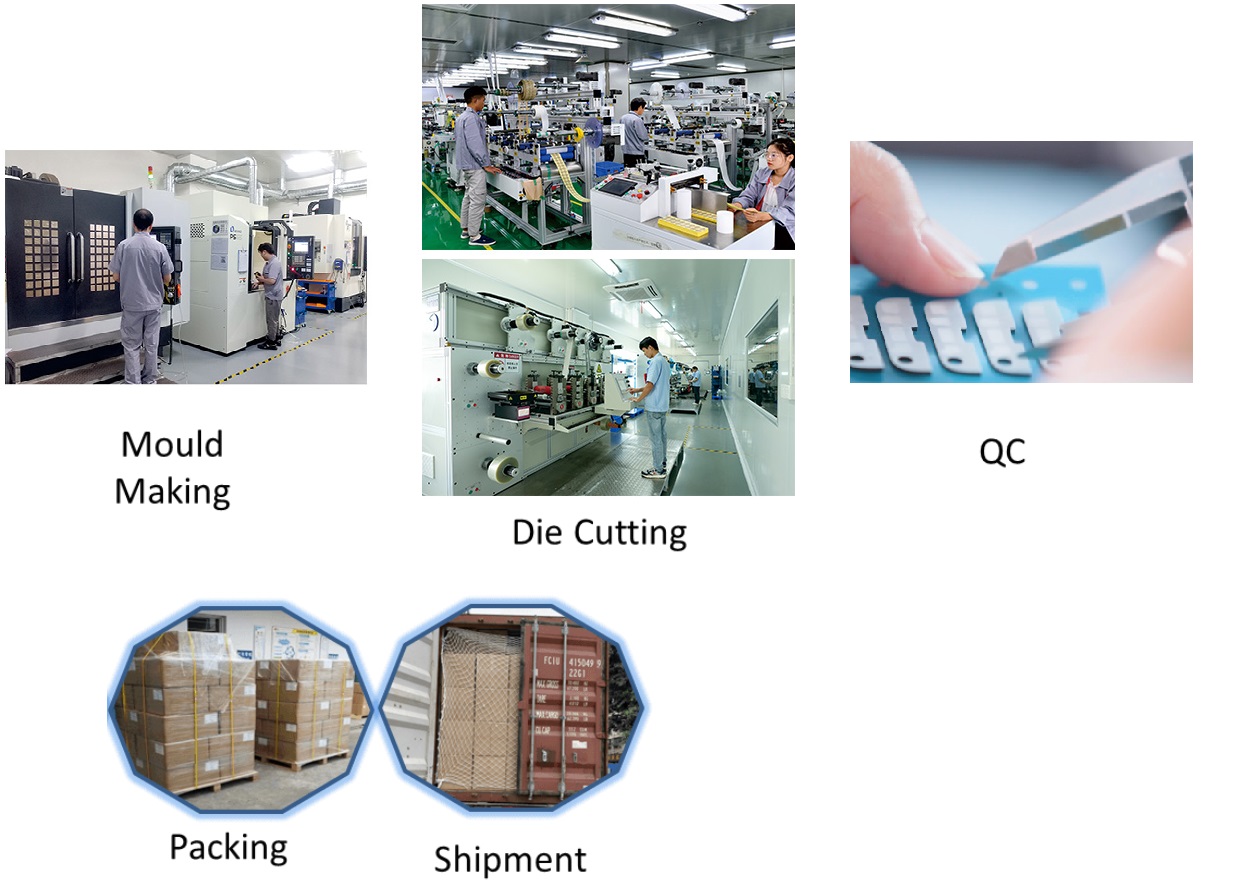

Lanxin's professional edge lies in its advanced manufacturing capabilities and strict quality control. Our state - of - the - art production lines enable precise die - cutting of EVA foam, ensuring accurate dimensions and consistent performance. We can customize EVA foam sealing products according to specific customer requirements, whether it's adjusting the density, thickness, or shape. Additionally, our EVA materials meet high - standard environmental and safety regulations, ensuring long - lasting durability and reliability. With Lanxin's EVA foam gaskets, eva seals, and eva foam sealing solutions, customers can expect top - notch quality and optimal sealing performance.

Images for reference

Producing Process

Quality standard

Lanxin's EVA foam gasket quality is 100% according to ISO9001 Standard. We seriously take care of the quality control from IQC to OQC, throughout each step of the production.

Lanxin dedicated to strict quality control and thoughtful customer service. We strive to exceed our customers' expectation in all aspects of product manufacturing process, and recognize our great responsibilities to our customers.

FAQ

Q1: How soon can I get a precise quotation for custom die cutting insulated materials ?

A1: Please send us your inquiry by email or phone call. Once we confirm the design (Feature details with parameters), material, color, qty, we can provide quotation within 24 HOURS.

Q2: Can I get a free sample, how long will it take?

A2: a. For standard products we have in stock, YES for free sample, but the express fee will be charged in advance. Mostly, it takes 3-10 days.

b. For custom products, sample fee is determined by the detailed sample requirements. Normally, it takes 7-15 days.

Q3: Can you make custom parts based on my sample?

A3: Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing for production.