Product description

| ITEM | Mica plates | ||

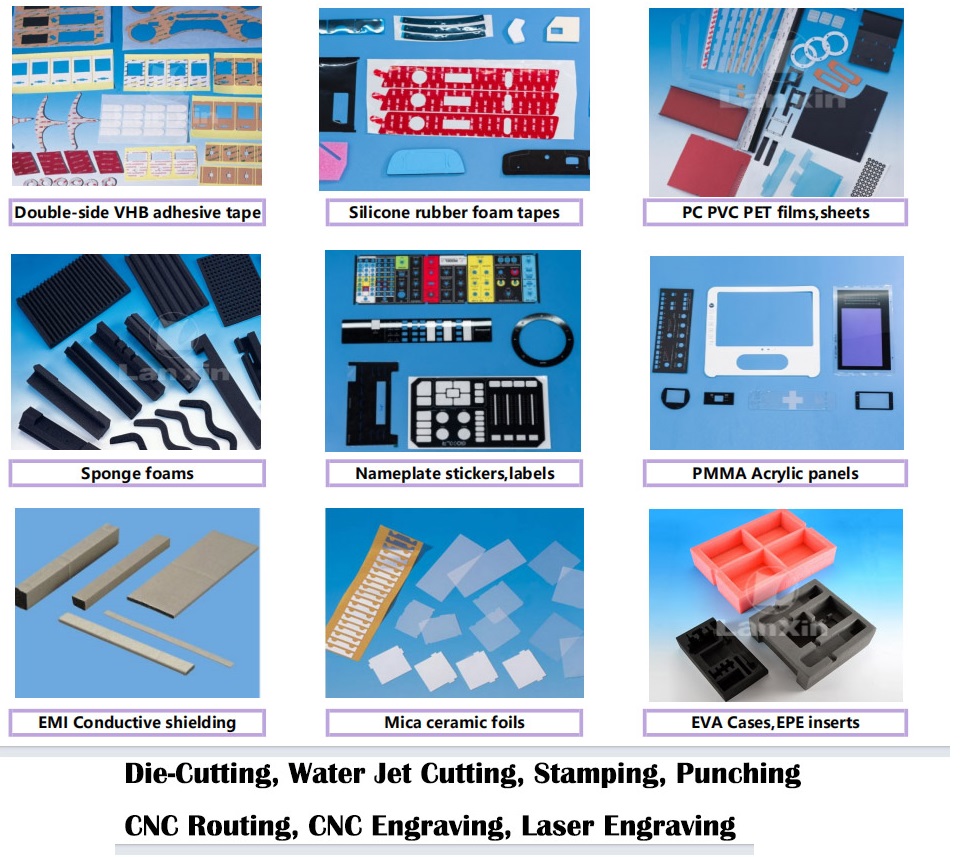

| Material | Die-Cutting materials can improve efficiency and output quality. Here are just a few of the materials that we can die-cut:

|

| Certificate | IATF 16949:2016 / ISO 9001:2015 / ISO 45001:2018 / ISO 14001:2015 /REACH/ROHS/MSDS/LFGB/F D A |

| Drawing Format | .stp / .step / .igs /.stl /.dwg / .pdf |

| Cutting types | Rotary die-cutting, flatbed die-cutting, waterjet cutting, CNC, etc... |

Mica plates, produced by die-cutting mica materials, are highly valued across multiple industries for their distinct properties. Mica plates offer excellent electrical insulation, high thermal resistance, and mechanical flexibility. In the electrical industry, they are crucial. In high-voltage transformers, their precise die-cutting electronic material shapes fit perfectly to insulate between windings, preventing arcing and short-circuits. In electrical switchgear, they insulate and separate electrical contacts, withstanding high-temperature switching operations. In the electronics industry, mica plates are used in printed circuit boards (PCBs). They insulate between conductive layers and help dissipate heat, vital for high-density and high-power PCB applications. For instance, in power electronics modules, they isolate semiconductor devices from heat sinks while facilitating heat transfer. In industrial heating equipment like ovens and furnaces, die-cutting electronic material mica plates insulate heating wires. They endure high temperatures up to several hundred degrees Celsius, and their die-cut shape enables easy installation, ensuring safe and efficient heating equipment operation.

Lanxin Company demonstrates remarkable advantages in die-cutting mica plates and other electronic materials, catering to the strict demands of the electronics industry.

1. Precision Engineering for Mica Plates

Our advanced die-cutting technology ensures mica plates are processed with dimensional accuracy up to ±0.05mm, maintaining their excellent electrical insulation and high-temperature resistance (withstanding up to 600°C). This precision is critical for applications in power supplies, circuit boards, and heat-dissipating components, where consistent thickness and edge smoothness are essential to prevent short circuits and thermal stress.

2. Versatility in Electronic Materials Processing

Beyond mica plates, we excel in die-cutting various electronic materials:

- Thermal interface materials(e.g., silicone pads, gap fillers) for efficient heat dissipation in CPUs and power modules

- Conductive silicone sheetsfor EMI shielding in smartphones and laptops

- Insulating films (such as PI, PET) for battery separators and flexible circuit protection

3.Technical Edge & Custom Solutions

- State-of-the-art CNC die-cutting machines with automated vision systems for complex geometries

- Material-specific processing know-how, including anti-static treatments and laminating techniques

- Customizable solutions for thickness (0.1mm-5mm), shape, and surface finishes to meet unique design requirements

Rigorous Quality Assurance

Each die-cut component undergoes multi-stage testing for insulation resistance, thermal conductivity, and dimensional stability. Our compliance with ISO 9001 and IPC standards ensures reliability in high-reliability applications like automotive electronics and aerospace devices. Lanxin's integration of precision technology, material expertise, and strict quality control makes us a trusted partner for advanced die-cutting solutions in the electronics sector.

Images for reference

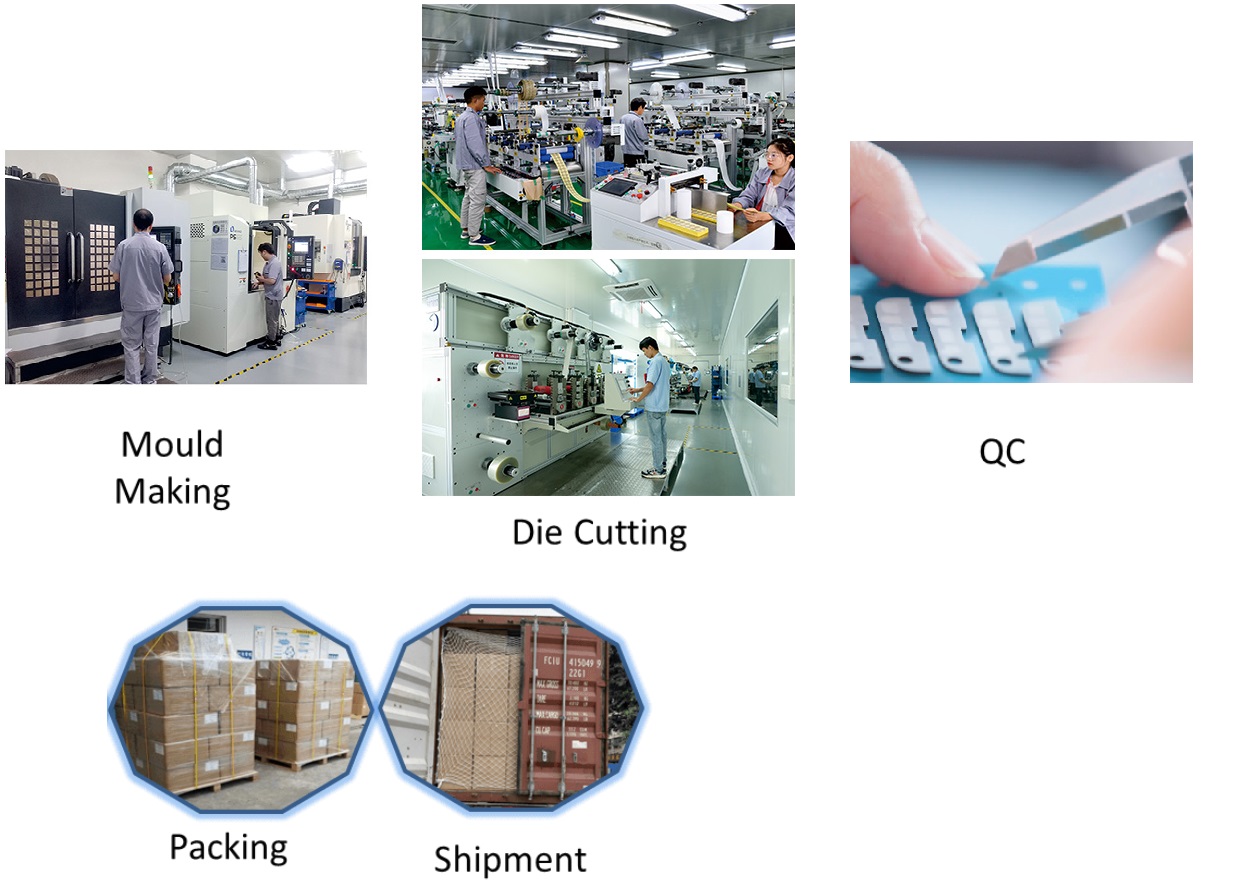

Producing Process

Quality standard

Lanxin's insulation materials quality is 100% according to ISO9001 Standard. We seriously take care of the quality control from IQC to OQC, throughout each step of the production.

FAQ

Q1: How soon can I get a precise quotation for custom die cutting insulated materials ?

A1: Please send us your inquiry by email or phone call. Once we confirm the design (Feature details with parameters), material, color, qty, we can provide quotation within 24 HOURS.

Q2: Can I get a free sample, how long will it take?

A2: a. For standard products we have in stock, YES for free sample, but the express fee will be charged in advance. Mostly, it takes 3-10 days.

b. For custom products, sample fee is determined by the detailed sample requirements. Normally, it takes 7-15 days.

Q3: Can you make custom parts based on my sample?

A3: Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing for production.