Product description

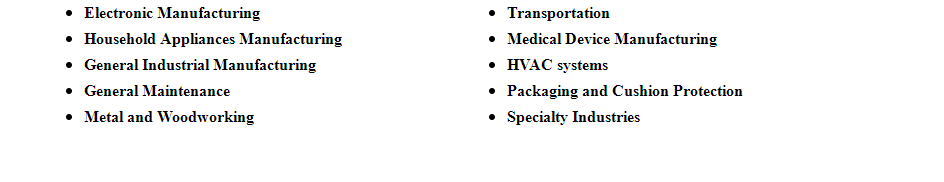

Many of the die-cutting materials we work with are already used in a variety of industries:

| ITEM | EMI shielding conductive fabric gasket | ||

| Material | Die-Cutting materials can improve efficiency and output quality. Here are just a few of the materials that we can die-cut:

|

| Certificate | IATF 16949:2016 / ISO 9001:2015 / ISO 45001:2018 / ISO 14001:2015 /REACH/ROHS/MSDS/LFGB/F D A |

| Drawing Format | .stp / .step / .igs /.stl /.dwg / .pdf |

| Cutting types | Rotary die-cutting, flatbed die-cutting, waterjet cutting, CNC, etc... |

EMI Shielding Product: Conductive Fabric Gasket?

A conductive fabric gasket, one kind of insulating materials, more commonly referred to as a fabric-over-foam gasket, is almost as straightforward as it sounds: it's a type of EMI gasket that is made of conductive fabric material, that has been coated or infused with conductive materials such as metal particles or carbon.

This type of gasket is designed to provide electrical conductivity between two surfaces, typically in electronic devices or equipment where electromagnetic interference (EMI) needs to be minimized. The need for this type of gasket extends across many different applications – everything from aerospace and defense to medical devices and space exploration.

An effective conductive fabric gasket works by creating a conductive path between two mating surfaces. This seal reduces the EMI that can occur between the two surfaces, and restricts ingress and egress of EMI. The gasket is used to provide a seal that is both conductive and flexible.

Conductive fabric gaskets are made from fabric that has been coated with or had conductive particles distributed throughout it which is placed over a conductive foam core. These gaskets are typically more compressible than their conductive elastomer counterpart, which makes them ideal for applications that require a high degree of flexibility.

Conductive fabric gaskets are also effective at providing EMI/RFI shielding and are often used in applications where weight and space constraints are critical.

Alternative EMI Shielding Solutions

While fabric-over-foam gaskets and conductive elastomers are popular choices for EMI shielding, there are other options available depending on your specific needs:

EMI Shielding Tape: This adhesive-backed tape is useful for quick fixes or prototyping. It's easy to apply and can be an effective solution for covering small gaps or seams in enclosures.

Conductive Foam Gaskets: These gaskets are made entirely of conductive foam and can be a good choice when a softer, more compressible option is needed.

Mesh Gaskets: Made from knitted wire mesh, these gaskets offer excellent shielding effectiveness and are particularly useful in high-temperature applications.

Form-In-Place (FIP) Gaskets: These gaskets are dispensed as a liquid and cure in place, allowing for precise application in complex geometries.

Metallic Gaskets: For extreme environments or very high shielding requirements, solid metal gaskets may be necessary.

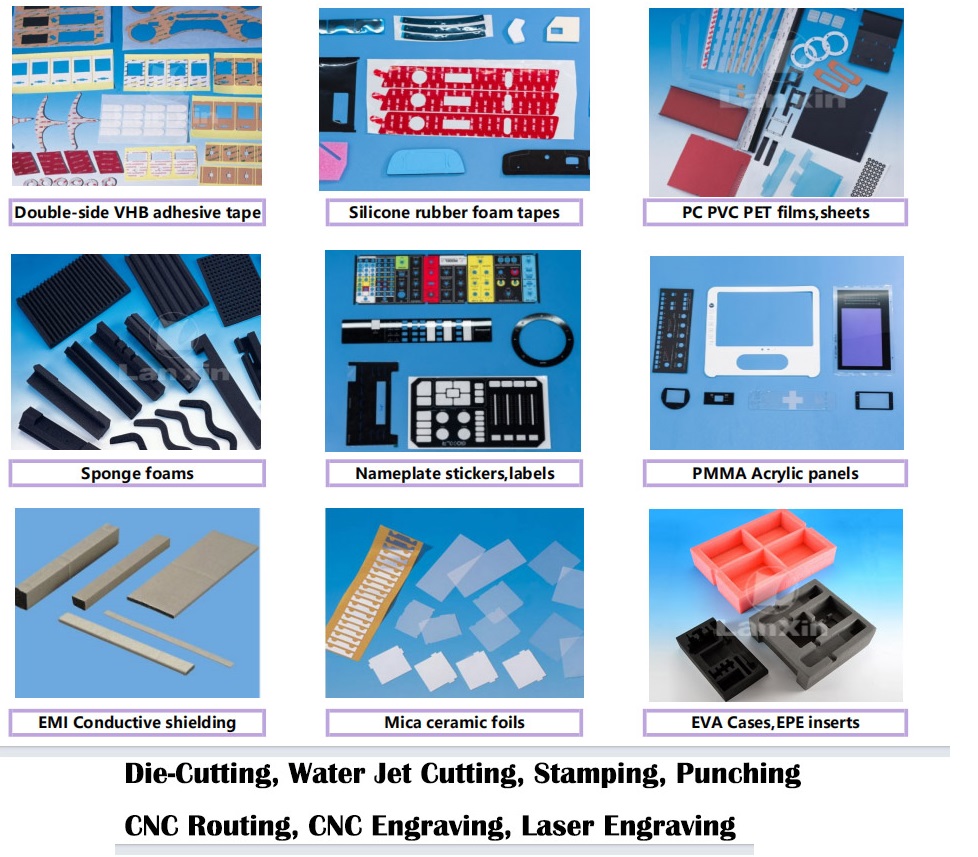

Images for reference

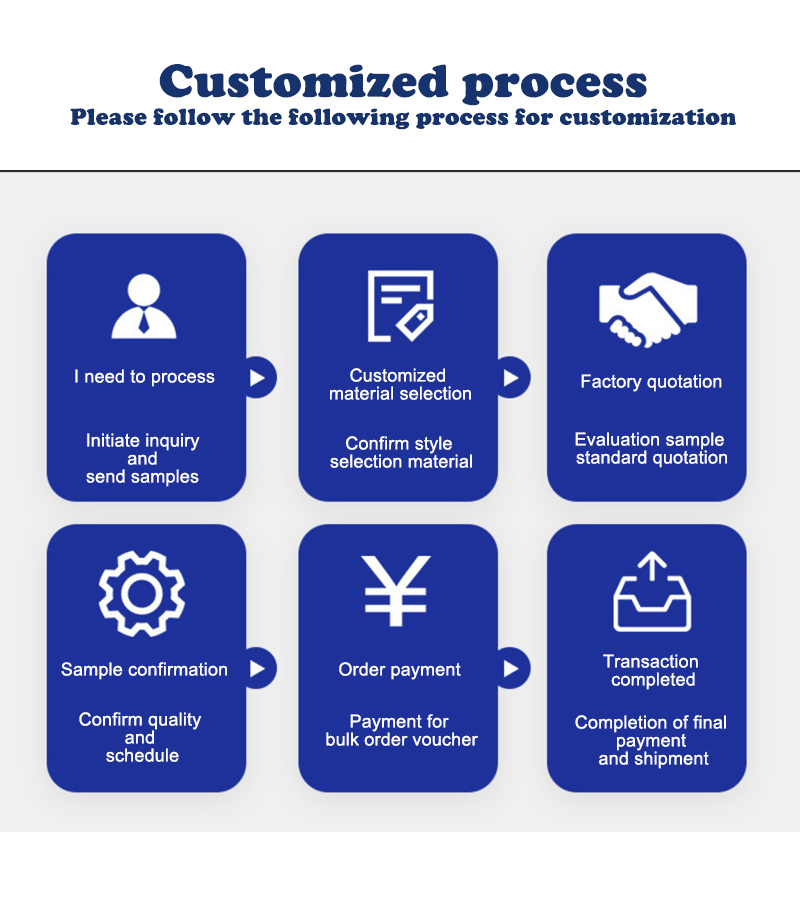

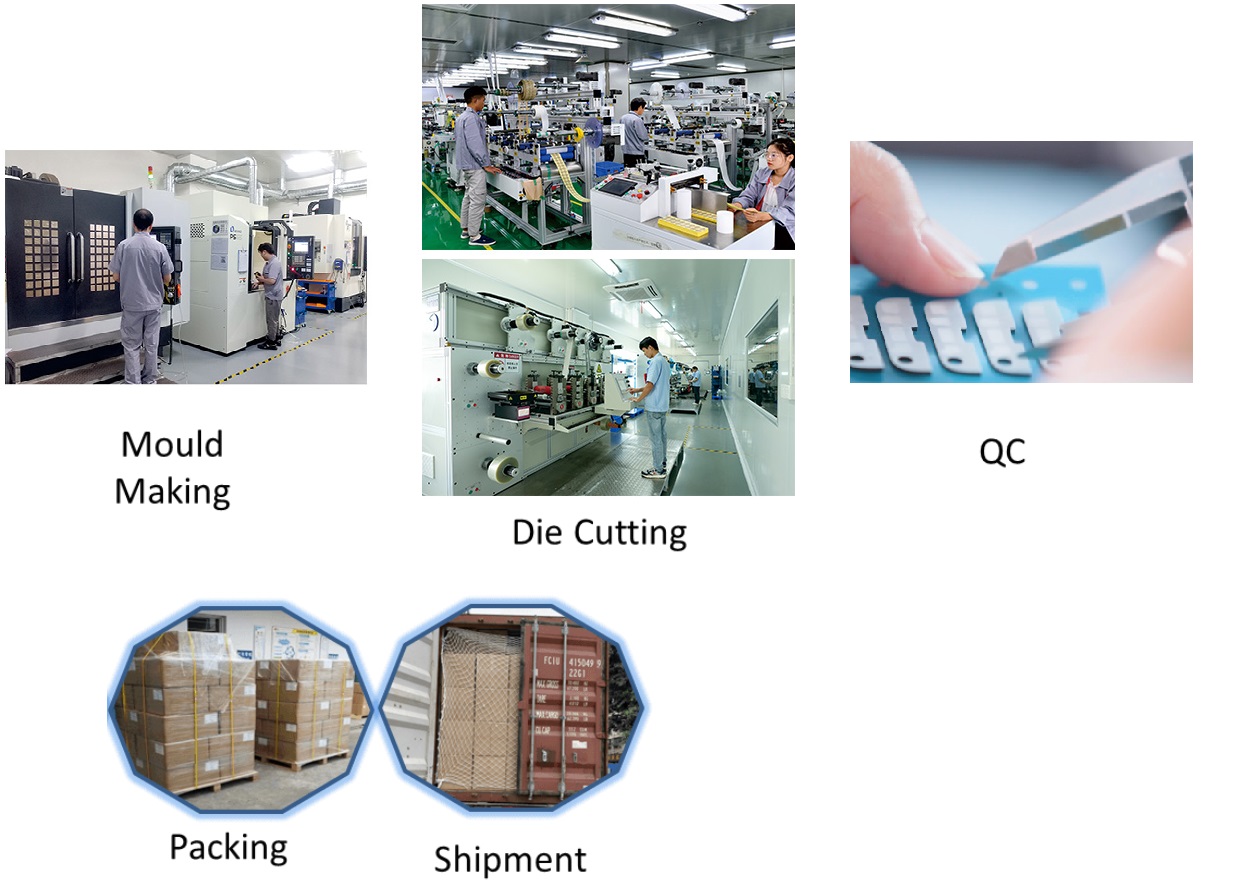

Producing Process

Quality standard

Lanxin's insulating materials quality is 100% according to ISO9001 Standard. We seriously take care of the quality control from IQC to OQC, throughout each step of the production.

Lanxin dedicated to strict quality control and thoughtful customer service. We strive to exceed our customers' expectation in all aspects of product manufacturing process, and recognize our great responsibilities to our customers.

FAQ

Q1: How soon can I get a precise quotation for custom die cutting insulated materials ?

A1: Please send us your inquiry by email or phone call. Once we confirm the design (Feature details with parameters), material, color, qty, we can provide quotation within 24 HOURS.

Q2: Can I get a free sample, how long will it take?

A2: a. For standard products we have in stock, YES for free sample, but the express fee will be charged in advance. Mostly, it takes 3-10 days.

b. For custom products, sample fee is determined by the detailed sample requirements. Normally, it takes 7-15 days.

Q3: Can you make custom parts based on my sample?

A3: Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing for production.