Product description

| ITEM | Custom Molded Rectangular Flat Silicone Rubber Gasket Seals |

| Material | EPDM, NBR, SBR, NR, Silicone(VMQ), Neoprene(CR), HNBR, XNBR, FKM, FFKM, FVMQ, FLAS, PTFE, PU, ECO, IIR, ACR, etc... |

| Certificate | IATF 16949:2016 / ISO 9001:2015 / ISO 45001:2018 / ISO 14001:2015 /REACH/ROHS/MSDS/LFGB/F D A |

| Drawing Format | .stp / .step / .igs /.stl /.dwg / .pdf |

| Function | Industrial parts /daily supply / Automotive/ Medical device, etc... |

Rubber sealing rings are indispensable across multiple industries, with each type of rubber offering distinct advantages. Nitrile Rubber (NBR) stands out for its outstanding oil resistance, making it a top choice for automotive engines, especially in sealing oil pans, transmissions, and fuel lines. Ethylene Propylene Diene Monomer (EPDM) rubber excels in weather resistance, enduring harsh outdoor conditions, and is widely used for roofing and automotive door/window seals.

Rubber Sealing Rings: Material Advantages & Applications

Nitrile Rubber (NBR)

• Superior oil resistance for automotive engine seals (oil pans, fuel lines)

• Abrasion-tolerant for industrial machinery

EPDM

• Exceptional weather resistance for outdoor use (roofing, vehicle door seals)

• Chemical stability suitable for chemical plants

Silicone o-rings

• High-temp tolerance for engines, ovens, and exhaust systems

• Cold flexibility and electrical insulation for electronics

FKM/Viton

• Extreme chemical resistance for pharmaceutical/chemical sectors

• Heat resistance and low gas permeability for aerospace/high-pressure systems

Butyl Rubber

• Ultra-low gas permeability for tire inner tubes and gas tanks

• Vibration damping and water resistance

APAC Leading provider in rubber sealing rings & silicone o-rings, Lanxin delivers precision and reliability:

Advanced Manufacturing

• Precision die-cutting and molding rubber sealing ring (tolerances ±0.05mm)

• Customizable dimensions, hardness, and heat/chemical resistance

R&D Innovation

• Formulation optimization for enhanced durability and performance sealing ring

Quality Assurance

• Strict QC from raw materials to final testing

• Compliance with international standards for electronics, automotive, and medical applications

Lanxin's silicone o-rings ensure leak-proof seals, biocompatibility, and long-term reliability across diverse industries.

Images for reference

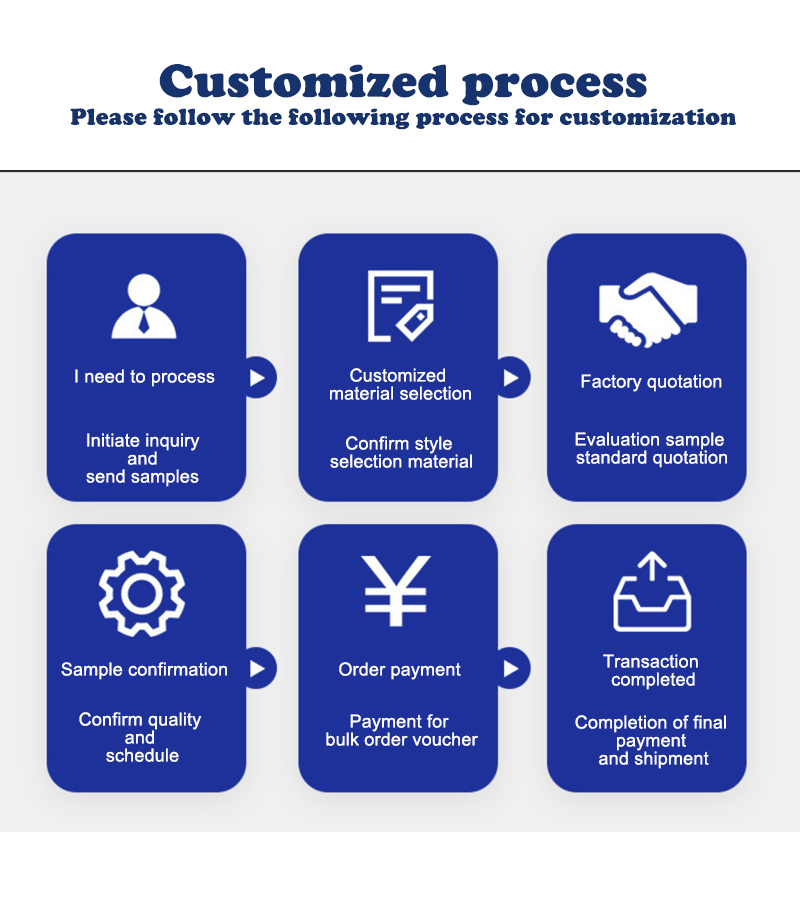

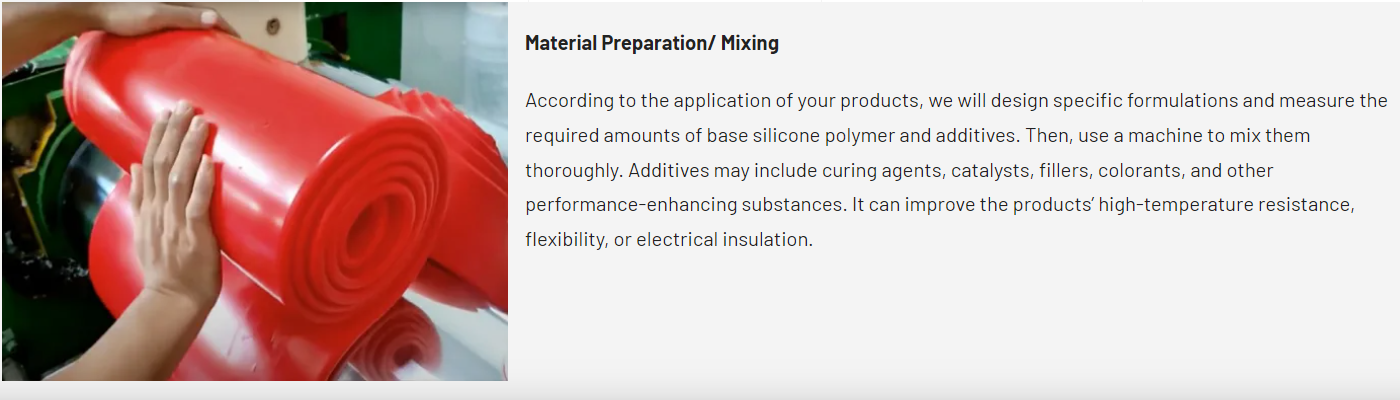

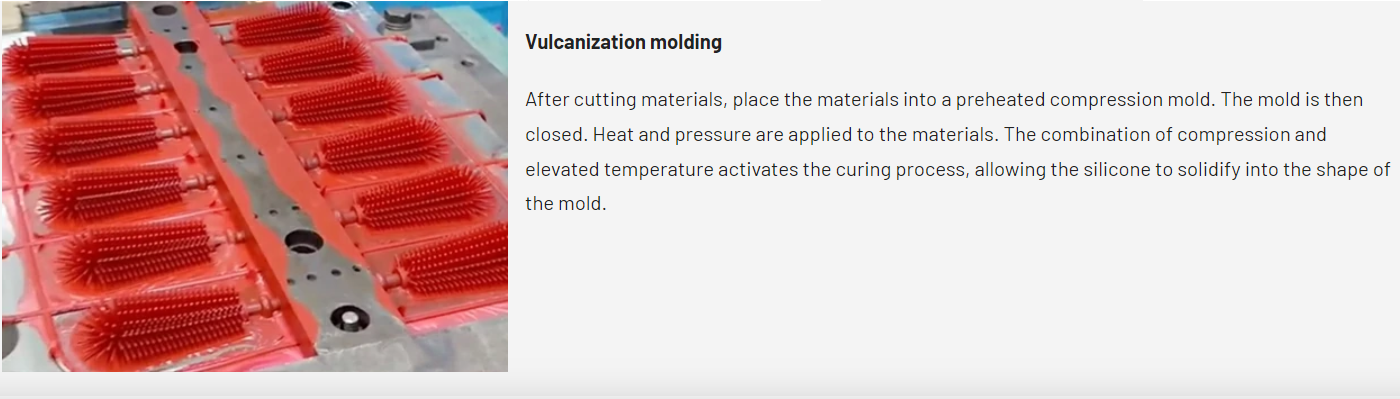

Producing Process

Quality standard

At lanxin, the tolerance can be controlled at 0.02-0.1mm by using good steel material, good located pins, and good mold-making equipment.

FAQ

Q1: How soon can I get a precise quotation for custom silicone o-ring, rubber sealing ring, gasket ?

A1: Please send us your inquiry by email or phone call. Once we confirm the design (Feature details with parameters), material, color, qty, we can provide quotation within 24 HOURS.

Q2: Can I get a free sample, how long will it take?

A2: a. For standard products we have in stock, YES for free sample, but the express fee will be charged in advance. Mostly, it takes 3-10 days.

b. For custom products, sample fee is determined by the detailed sample requirements. Normally, it takes 7-15 days.

Q3: Can you make custom parts based on my sample?

A3: Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing for production.