Product description

Many of the die-cutting materials we work with are already used in a variety of industries:

| ITEM | epdm sealing |

| Material | Die-Cutting materials can improve efficiency and output quality. Here are just a few of the materials that we can die-cut: Papers Rubbers Label Stocks VHB Specialty Materials

| Pressure-Sensitive Tapes Gaskets Films Foams Foils

|

|

| Certificate | IATF 16949:2016 / ISO 9001:2015 / ISO 45001:2018 / ISO 14001:2015 /REACH/ROHS/MSDS/LFGB/F D A |

| Drawing Format | .stp / .step / .igs /.stl /.dwg / .pdf |

| Cutting types | Rotary die-cutting, flatbed die-cutting, waterjet cutting, CNC, etc... |

EPDM rubber sealing is a widely adopted and highly effective sealing solution, relying on the exceptional properties of Ethylene Propylene Diene Monomer (EPDM) rubber. EPDM rubber is a synthetic elastomer that has carved out a niche for itself in the sealing domain due to its unique characteristics.

One of the most prominent features of EPDM rubber is its remarkable resistance to environmental elements. It demonstrates excellent resilience against ultraviolet (UV) rays, meaning it can be exposed to sunlight for extended periods without significant degradation. This UV resistance makes it an ideal choice for outdoor sealing applications, such as in roofing systems where it guards against water penetration while enduring the sun's rays day in and day out. Additionally, it can tolerate a broad spectrum of temperatures. Whether in the frigid cold of winter or the sweltering heat of summer, EPDM rubber maintains its flexibility and structural integrity, ensuring consistent sealing performance across diverse climates.

The sealing mechanism of EPDM rubber is straightforward yet highly effective. When used as a seal, EPDM rubber is typically compressed between two mating surfaces. Its inherent flexibility allows it to conform to the irregularities of these surfaces, creating a tight seal that prevents the passage of fluids, gases, or particles. The material's elasticity enables it to maintain this seal even under dynamic conditions, such as vibrations or minor movements in the connected components. In the automotive industry, EPDM rubber sealing is used in multiple critical applications. It seals engine components, preventing the leakage of essential fluids like oil, coolant, and fuel. In vehicle doors and windows, EPDM rubber seals provide a weather - tight and sound - insulating barrier, enhancing the comfort of passengers by keeping out rain, wind, and external noise. In the construction industry, EPDM rubber seals are integral to roofing systems, where they play a crucial role in preventing water infiltration and protecting buildings from water damage. They are also used in plumbing systems to ensure leak - free connections between pipes and fixtures. In the industrial sector, EPDM rubber seals are employed in a wide range of equipment, from pumps and valves to storage tanks, ensuring the safe and efficient operation of machinery. EPDM rubber sealing offers a reliable, durable, and versatile solution for a vast array of sealing requirements. Its ability to resist environmental and chemical challenges, combined with its effective sealing mechanism, makes it an indispensable choice across numerous industries, contributing to the proper functioning and safety of various systems and equipment.

Images for reference

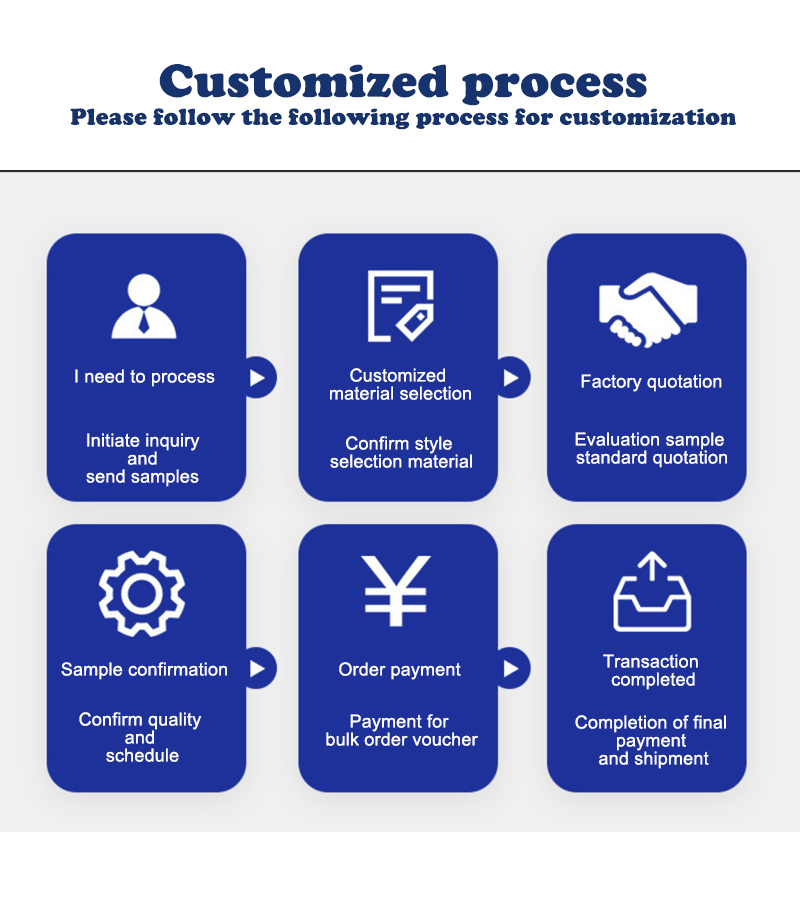

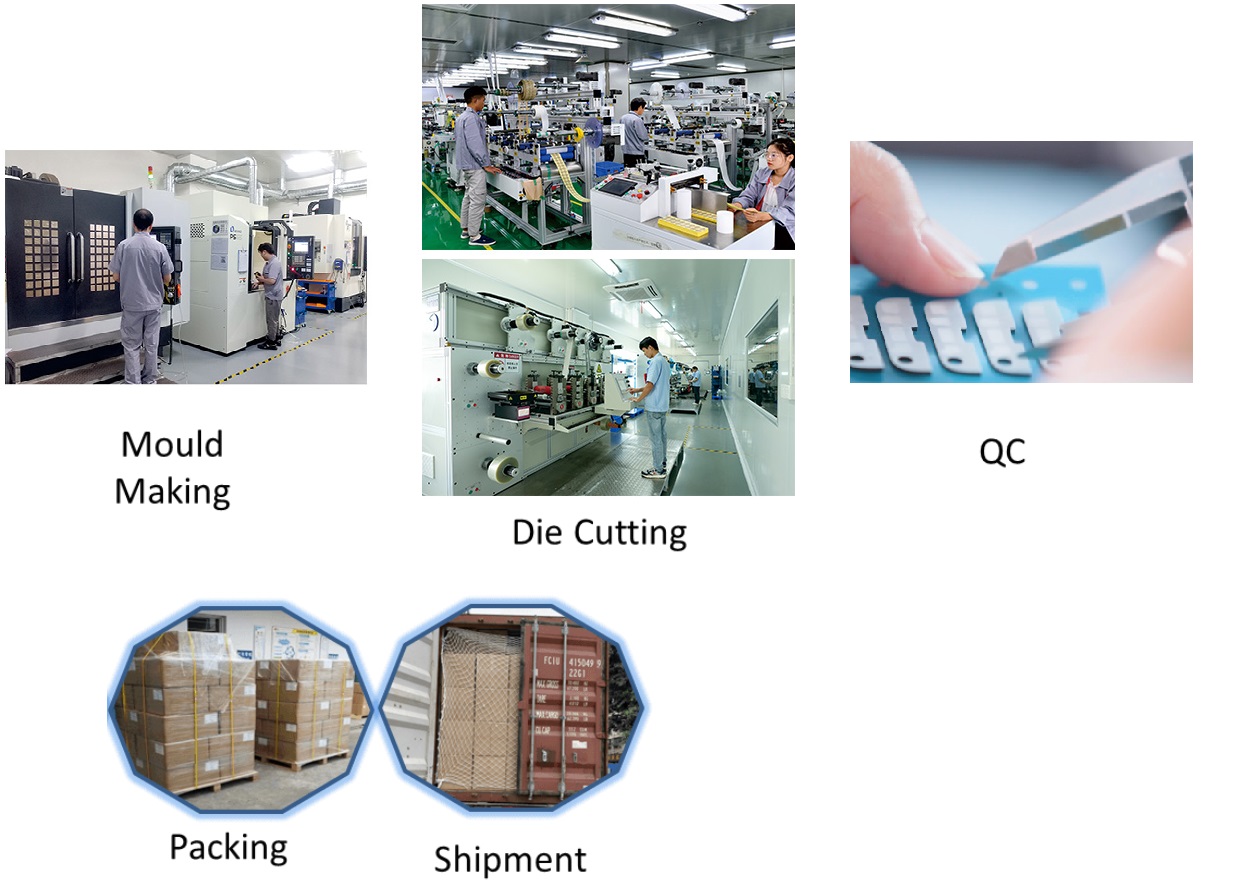

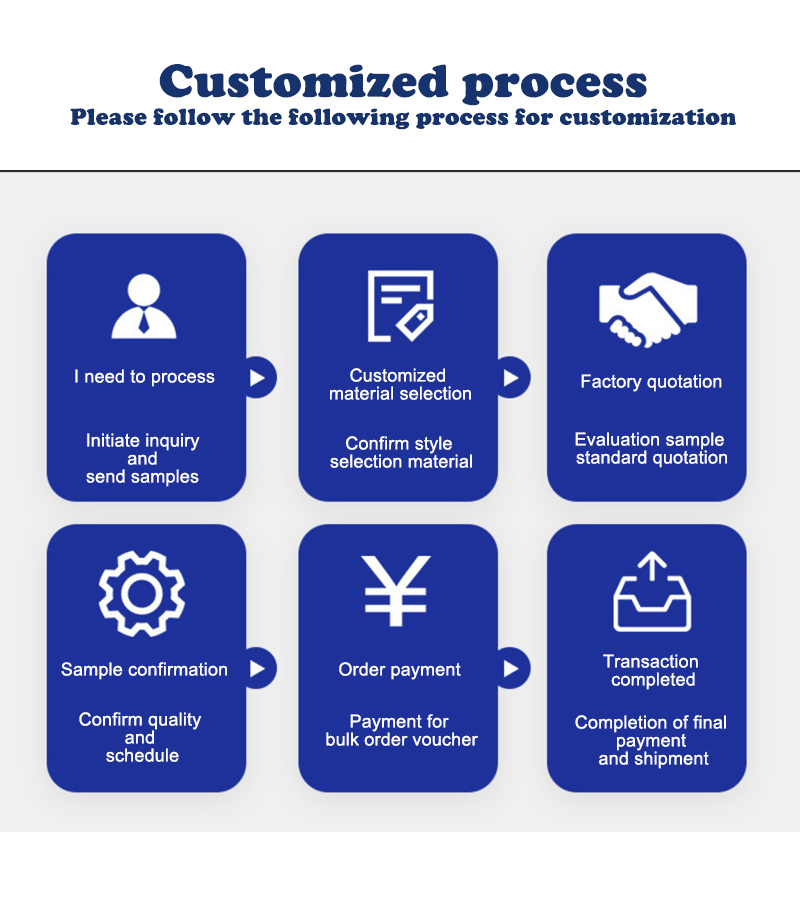

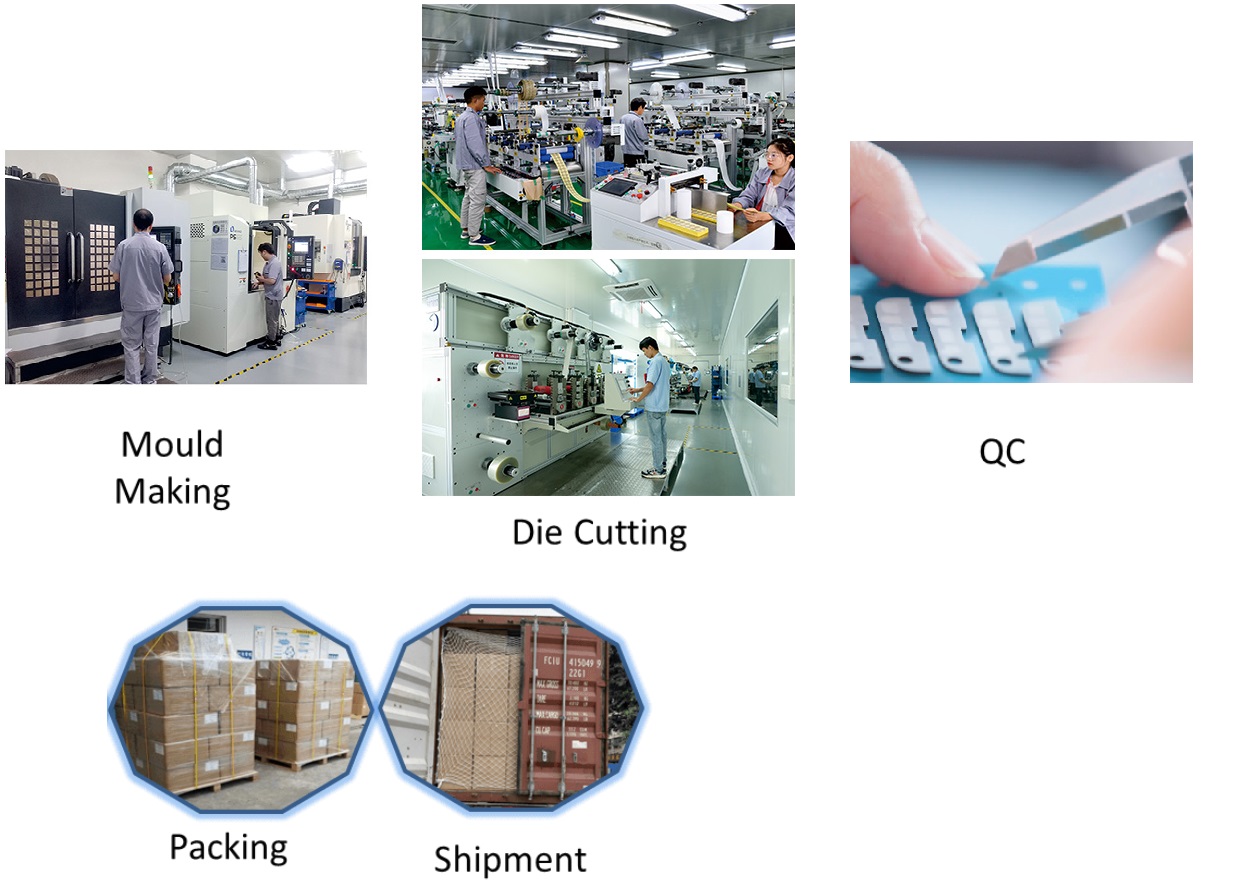

Producing Process

Quality standard

Lanxin's insulation materials quality is 100% according to ISO9001 Standard. We seriously take care of the quality control from IQC to OQC, throughout each step of the production.

Lanxin dedicated to strict quality control and thoughtful customer service. We strive to exceed our customers' expectation in all aspects of product manufacturing process, and recognize our great responsibilities to our customers.

FAQ

Q1: How soon can I get a precise quotation for custom die cutting insulated materials ?

A1: Please send us your inquiry by email or phone call. Once we confirm the design (Feature details with parameters), material, color, qty, we can provide quotation within 24 HOURS.

Q2: Can I get a free sample, how long will it take?

A2: a. For standard products we have in stock, YES for free sample, but the express fee will be charged in advance. Mostly, it takes 3-10 days.

b. For custom products, sample fee is determined by the detailed sample requirements. Normally, it takes 7-15 days.

Q3: Can you make custom parts based on my sample?

A3: Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing for production.

Q4: What does your OEM service include?

A4: We follow up your request from the design idea to the bulk production.

a. You can provide 3D drawing to us, then our engineers and production teams evaluate the design and quote you the precise cost.

b. If you don’t have 3D drawing, you can provide 2D drawing or draft with features details with full dimensions, we can draft 3D drawing for you with fair charge.

c. You can also customize Logo on the product surface, package, color box or carton.

d. We also provide assembly service for the OEM parts.

Q5. What is your payment term?

A5: We accept T/T, Paypal, Western Union, L/C, Alibaba Trade Assurance.