Product description

| Certificate | IATF 16949:2016 / ISO 9001:2015 / ISO 45001:2018 / ISO 14001:2015 /REACH/ROHS/MSDS/LFGB/F D A |

| Drawing Format | .stp / .step / .igs /.stl /.dwg / .pdf |

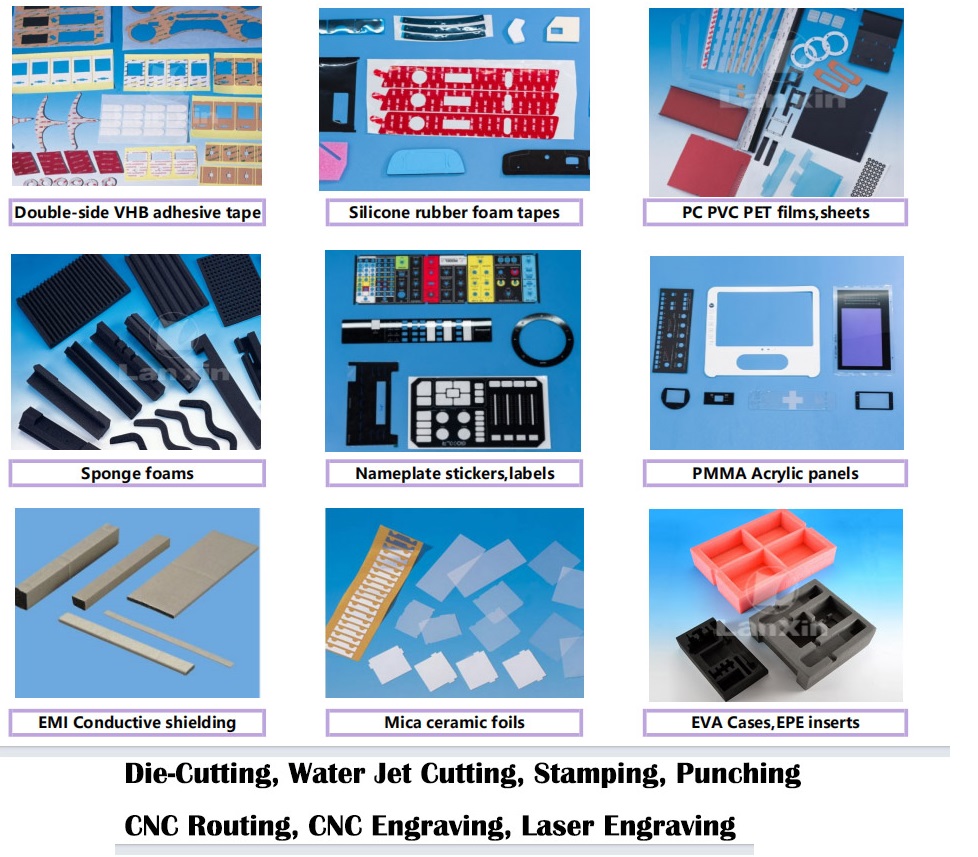

| Cutting types | Rotary die-cutting, flatbed die-cutting, waterjet cutting, CNC, etc... |

Introduction to Die Cutting Silicone Gaskets

Die Cutting Silicone Gaskets are custom rubber parts that play a crucial role in various industries. They are used to prevent leaks between different substrate sections, ensuring a tight seal in machinery, equipment, and devices. These silicone gaskets are made from silicone elastomer, a highly versatile and durable material known for its excellent resistance to extreme temperatures, UV and ozone exposure, and aging. Lanxin excels in producing high-quality die cutting silicone gaskets, designed to meet a wide range of sealing and insulating needs. Our silicone gaskets precision-engineer to provide excellent sealing performance and reliability in various applications.

Lanxin——Custom Leading Silicone Rubber Gasket Manufacturer

Lanxin's silicone rubber gasket and rubber washer products excel with outstanding performance. These silicone rubber gaskets are widely utilized in multiple fields. In automotive engine sealing systems, silicone gaskets can withstand temperatures ranging from -60°C to 220°C, far exceeding the industry standard of -40°C to 180°C. For medical equipment, the silicone gaskets and rubber washers meet the ISO 10993 biocompatibility certification, with leachables less than 0.5mg/L, ensuring a sterile connection environment. In electronic device waterproof enclosures, they achieve an IPX8 rating, capable of withstanding continuous pressure at a depth of 10 meters for 24 hours.

Lanxin's professional edge lies in its precision compression molding technology, which controls tolerances at ±0.03mm, compared to the industry average of ±0.1mm. The company's material innovation is also remarkable, as its self-developed fluorosilicone rubber formula enhances chemical resistance by 40%. This allows Lanxin to customize solutions for extreme environments, such as the cryogenic vacuum conditions in aerospace. All products have obtained the UL 94 V-0 flame retardant certification, with a compression set of less than 15% (compared to the industry average of 25%), guaranteeing a silicone gasket lifespan of over 10 years.

Images for reference

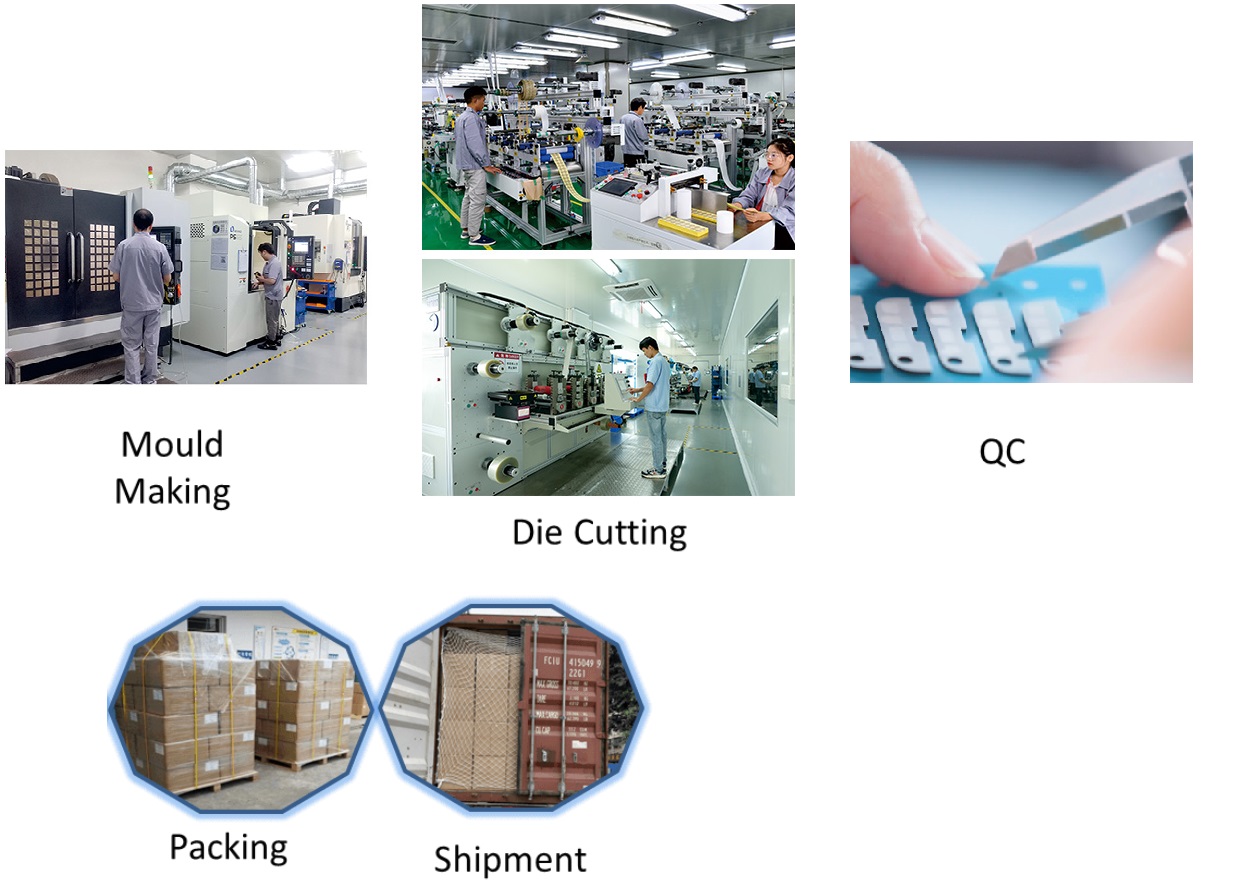

Producing Process

Quality standard

Lanxin's insulation materials quality is 100% according to ISO9001 Standard. We seriously take care of the quality control from IQC to OQC, throughout each step of the production.

Lanxin dedicated to strict quality control and thoughtful customer service. We strive to exceed our customers' expectation in all aspects of product manufacturing process, and recognize our great responsibilities to our customers.

FAQ

Q1: How soon can I get a precise quotation for custom die cutting insulated materials ?

A1: Please send us your inquiry by email or phone call. Once we confirm the design (Feature details with parameters), material, color, qty, we can provide quotation within 24 HOURS.

Q2: Can I get a free sample, how long will it take?

A2: a. For standard products we have in stock, YES for free sample, but the express fee will be charged in advance. Mostly, it takes 3-10 days.

b. For custom products, sample fee is determined by the detailed sample requirements. Normally, it takes 7-15 days.

Q3: Can you make custom parts based on my sample?

A3: Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing for production.