Product description

| ITEM | Conductive Silicone Pad | ||

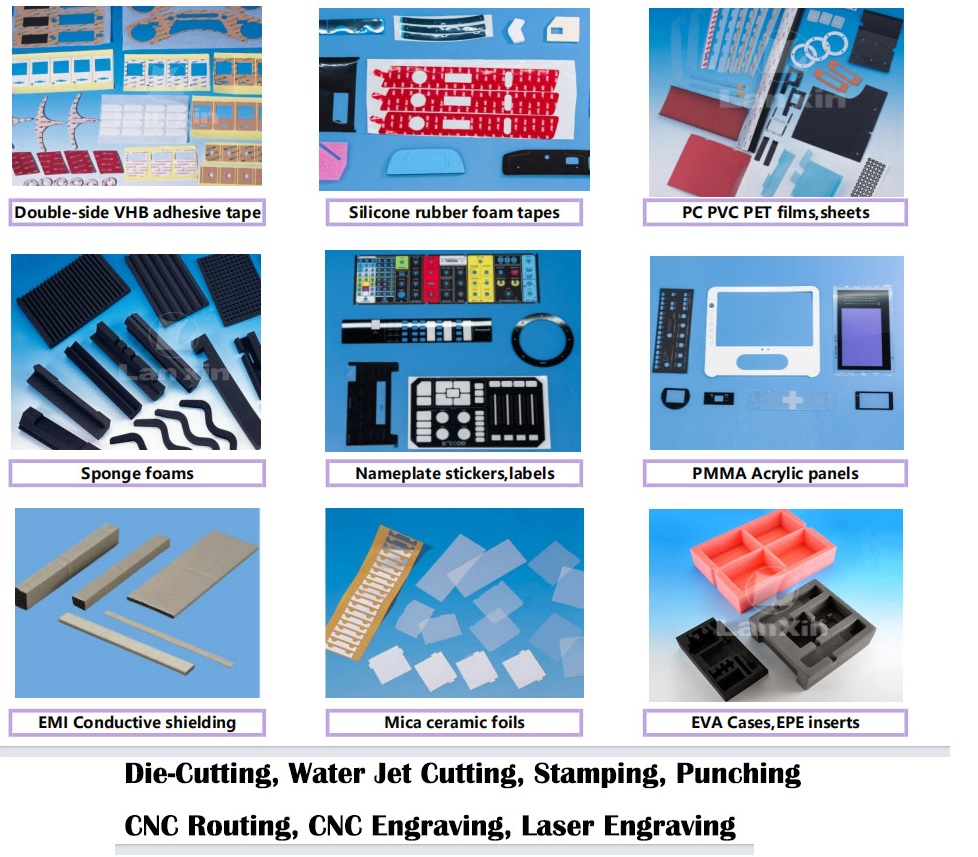

| Material | Die-Cutting materials can improve efficiency and output quality. Here are just a few of the materials that we can die-cut:

|

Conductive silicone pads and thermal interface pads are essential components across various industries. Conductive silicone pads are widely used in electronics to shield electromagnetic interference (EMI), ensuring the stable operation of sensitive circuits in devices like smartphones, laptops, and servers. Their conductivity allows them to effectively divert electromagnetic waves, preventing signal disruptions. Thermal interface pads, on the other hand, play a crucial role in heat dissipation. In high-performance CPUs, graphics cards, and power modules, these pads efficiently transfer heat from hot components to heat sinks, reducing operating temperatures and extending the lifespan of electronic devices.

Lanxin Company's expertise in producing these pads is unparalleled. Our advanced manufacturing facilities utilize precision molding and compounding techniques, enabling us to create conductive silicone pads with consistent conductivity and thermal interface pads with excellent heat transfer capabilities. We can customize the hardness, thickness, and size of these pads according to specific customer requirements, ensuring a perfect fit for diverse applications. Rigorous quality control processes are in place, with each pad undergoing strict testing for conductivity, thermal conductivity, and durability. With Lanxin's products, customers can rely on high-performance, reliable conductive silicone pads and thermal interface pads for their most demanding applications.

When it comes to die-cutting conductive silicone pads, we understand the importance of maintaining consistent conductivity throughout the process. Our solution involves using high-precision die-cutting machines that can accurately cut the pads to the required shape and size, ensuring minimal impact on the conductive properties of the silicone material. We also conduct rigorous in-process inspections, including conductivity testing at multiple stages of production, to guarantee product quality. For example, in a recent project for an electronics manufacturer, we were able to achieve a dimensional accuracy of ±0.05mm for the conductive silicone pads, while maintaining a stable conductivity within the specified range.

Images for reference

Quality standard

Lanxin has established a comprehensive quality control system. We source high - quality raw materials from reliable suppliers and subject them to strict incoming inspections. After production, each batch of pads undergoes a series of tests, including adhesion tests, thermal shock tests, and long - term reliability tests, to ensure they meet the highest industry standards. This multi-step quality assurance process has enabled us to maintain a defect rate of less than 0.5% in our die-cutting adhesive tape products, providing our customers with reliable and high-performance solutions.

FAQ

Q1: How soon can I get a precise quotation for custom die cutting insulated materials ?

A1: Please send us your inquiry by email or phone call. Once we confirm the design (Feature details with parameters), material, color, qty, we can provide quotation within 24 HOURS.

Q2: Can I get a free sample, how long will it take?

A2: a. For standard products we have in stock, YES for free sample, but the express fee will be charged in advance. Mostly, it takes 3-10 days.

b. For custom products, sample fee is determined by the detailed sample requirements. Normally, it takes 7-15 days.

Q3: Can you make custom parts based on my sample?

A3: Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing for production.