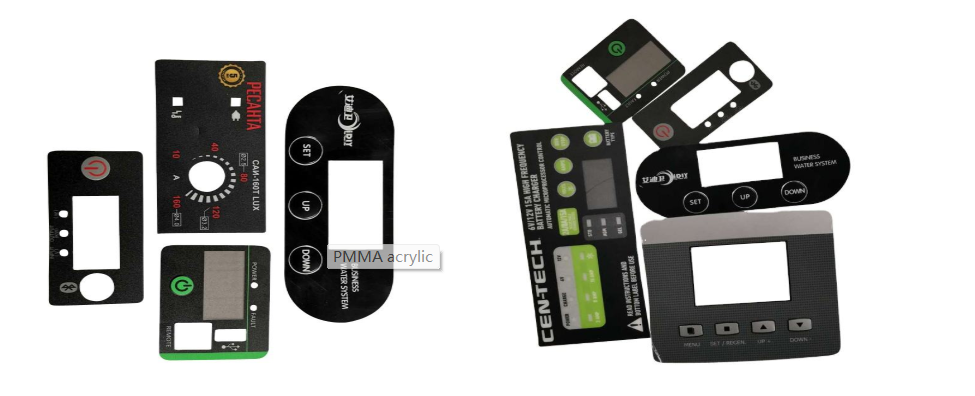

PMMA acrylic front panel, also called PMMA acrylic cover, has the advantages of high transparency, excellent optical properties, weather resistance, processing flexibility and environmental friendliness. It can greatly improve the visual effects of products, and ensure stable functions. Lanxin Industry supplies custom PMMA acrylic front panel according to your drawings or specific requirements.

Acrylic sheets have gradually become the panels of home appliances and equipment because of their many advantages. In terms of processing, acrylic sheets are easy to shape and cut; in terms of physical properties, acrylic sheets are light in weight and strong in impact resistance; they have good optical properties, high and stable transparency; they are good in weather resistance, not easy to age, and resistant to chemical corrosion; although the price of acrylic sheets materials is slightly higher, the comprehensive processing, transportation, installation and other costs are relatively low, so they are widely favored by terminal manufacturers.

We(Lanxin) offer acrylic material in transparent and various colour options. A UV print process is used for digital printing. Printing can be applied to both the front and back of the front panel.

| Thickness | 0.5mm~10mm |

| Applications | Electronic devices, Instruments, Home Appliances, Medical Devics, Industrial Equipment, and so on |

| Material | PMMA acrylic, PC polycarbonate, PET, PVC |

| Surface finished | glossy, matte |

Acrylic(PMMA) has high transparency and the reputation of “plastic crystal”. And has excellent weather resistance, especially used in outdoor, the crown of other plastics, and both good surface hardness and luster, processing plasticity.

VLT(Visible Light Transmission) The highest 93.5%

The surface hardness can reach 2H-4H

Excellent anti-static features

Surface pattern can be silk screen, UV printing

Related Products

Quality Control

Lanxin Company implements rigorous quality control protocols in processing acrylic front panels, ensuring precision, durability, and aesthetic excellence for electronic and industrial applications.

Material Sourcing & Certification

We source premium acrylic sheets from certified suppliers, verifying material specifications such as optical clarity (92% light transmittance), impact resistance, and thermal stability. Each batch undergoes inspection for surface defects, thickness uniformity (tolerance ±0.05mm), and compliance with RoHS/UL standards before entering production.

Precision Manufacturing Controls

Our CNC machining centers utilize diamond-tipped tools and vacuum clamping systems to minimize stress during cutting and shaping, achieving dimensional accuracy up to ±0.03mm for intricate contours and holes. Post-processing steps like flame polishing or mechanical buffing are meticulously controlled to eliminate burrs and enhance surface smoothness (Ra ≤ 0.2μm), critical for optical applications.

Optical & Functional Testing

--Visual Inspection: Automated vision systems detect micro-scratches, bubbles, or color inconsistencies, while manual checks ensure edge uniformity.

--Mechanical Testing: Adhesion tests for printed graphics, hardness measurements (Shore D 90 - 95), and thermal cycling (-40°C to +80°C) verify durability.

--Electrical Integration: For panels with embedded touch sensors or circuitry, we conduct continuity and insulation resistance tests to ensure functional reliability.

Environmental & Process Controls

Production occurs in climate-controlled cleanrooms (Class 10,000), minimizing dust contamination during printing, coating, or assembly. Anti-static measures prevent ESD damage, and traceability systems track each panel through every process step for full quality accountability.

Compliance & Customer Assurance

All acrylic front panels meet ISO 9001:2015 and IPC-610 standards. We provide detailed inspection reports and offer custom testing (e.g., salt spray, UV aging) to validate performance in harsh environments. Lanxin's dual focus on technical precision and rigorous quality protocols ensures acrylic front panels that combine aesthetic appeal with long-term functional reliability.

FAQ

Q1: How soon can I get a precise quotation for custom die cutting insulated materials ?

A1: Please send us your inquiry by email or phone call. Once we confirm the design (Feature details with parameters), material, color, qty, we can provide quotation within 24 HOURS.

Q2: Can I get a free sample, how long will it take?

A2: a. For standard products we have in stock, YES for free sample, but the express fee will be charged in advance. Mostly, it takes 3-10 days.

b. For custom products, sample fee is determined by the detailed sample requirements. Normally, it takes 7-15 days.

Q3: Can you make custom parts based on my sample?

A3: Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing for production.