Die cutting double sided adhesive tape serves as a versatile solution across numerous industries. In electronics, it bonds delicate components like circuit boards and displays, providing secure attachment while minimizing stress on sensitive parts. For automotive applications, it secures interior trims, seals gaps, and dampens vibrations, enhancing both aesthetics and functionality. In the packaging industry, it offers reliable sealing and labeling, ensuring products are well - protected during transit. Additionally, it's widely used in signage and graphic installations for a clean, seamless bond.

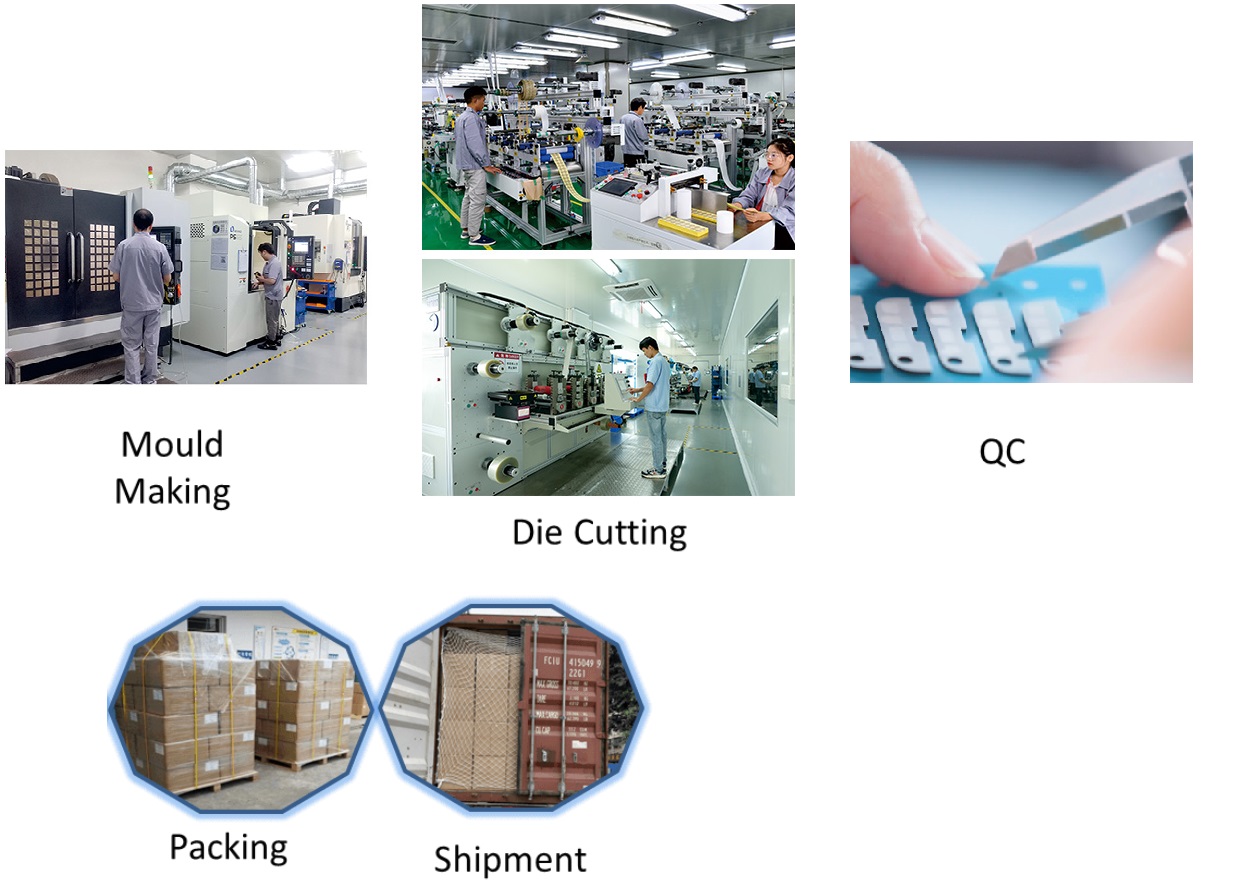

Lanxin Company stands out as a leading provider of die cutting double sided adhesive tape. Our professional advantages stem from decades of experience and cutting-edge technology. As an authorized partner of major adhesive tape manufacturers, we have access to a wide range of high - quality raw materials at competitive prices. Our die cutting machines, equipped with advanced digital control systems, achieve an astonishing dimensional accuracy of up to ±0.01mm, ensuring a perfect fit for every application. With a dedicated team of engineers, we offer customized solutions, tailoring the tape's thickness, adhesive strength, and shape to meet specific customer needs. Rigorous quality control procedures at every production stage guarantee consistent performance, making Lanxin the trusted choice for top-tier die cutting double sided adhesive tape products.

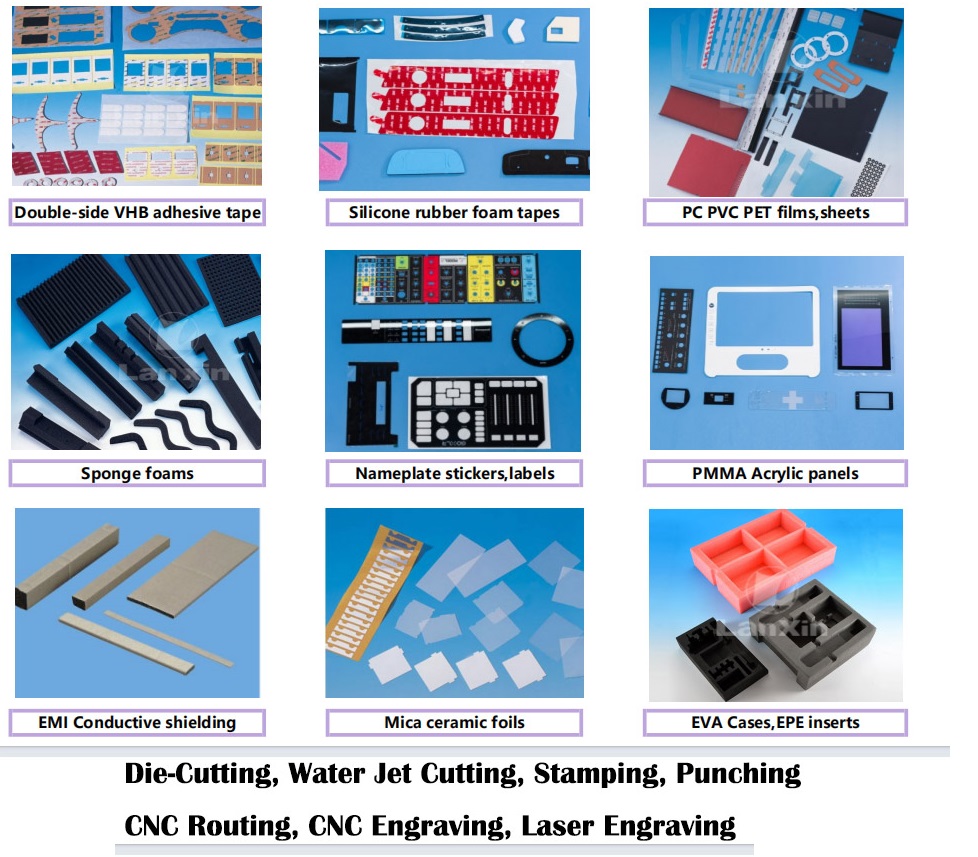

Lanxin Company offers tailored industry solutions with die cutting adhesive tape

Electronics Industry

In electronics, our tapes bond circuit board components, providing firm attachment and electrical insulation. For example, die cutting adhesive tapes with ±0.03mm thickness tolerance attach FPCs to rigid boards, withstanding vibrations and temperature changes. In smartphones and tablets, customizable-strength tapes secure displays, speakers, and batteries.

Automotive Industry

For automotive needs, our tapes fasten interior trims, reducing weight and noise. Die-cut foam-backed tapes seal doors and windows, improving comfort and reducing NVH. Heat-resistant tapes in the engine compartment, tolerating up to 150°C, secure wires and hoses.

Medical Industry

In the medical field, our biocompatible and sterilization-compatible tapes are used in device assembly. Die-cut single-sided tapes attach electrodes for ECG/EEG tests, ensuring a secure and comfortable connection.

Packaging Industry

For packaging, our high-strength die cut tapes seal cartons precisely. Tapes with features like tamper - evident or easy-open designs balance security and usability.

With advanced die-cutting process (tolerance 0.05-0.1mm accuracy), access to quality raw materials, and custom engineering, Lanxin meets diverse industry needs.

Lanxin's insulation materials quality is 100% according to ISO9001 Standard. We seriously take care of the quality control from IQC to OQC, throughout each step of the production.

A1: Please send us your inquiry by email or phone call. Once we confirm the design (Feature details with parameters), material, color, qty, we can provide quotation within 24 HOURS.

A2: a. For standard products we have in stock, YES for free sample, but the express fee will be charged in advance. Mostly, it takes 3-10 days.

b. For custom products, sample fee is determined by the detailed sample requirements. Normally, it takes 7-15 days.