According to industry media reports, Switzerland-based silicone 3D printing service provider Spectroplast AG has successfully completed its Series A financing. Although the specific amount of financing has not been disclosed, the financing was led by HZG Group, and existing investor AM Ventures also participated in the follow-up investment, showing the capital market's high recognition and confidence in Spectroplast.

Dr. Pablo Hafner, Chairman of Spectroplast, said: “We welcome the confidence of two leading venture capital firms in 3D printing start-ups. Through the cooperation with the HZG Group, we will not only receive new capital to further develop our company, but also gain valuable entrepreneurial momentum from industry leaders who have established metals as the new material for industrial 3D printing. We also expect to set industry standards in the field of silicones and elastomers.”

3d printed wearables

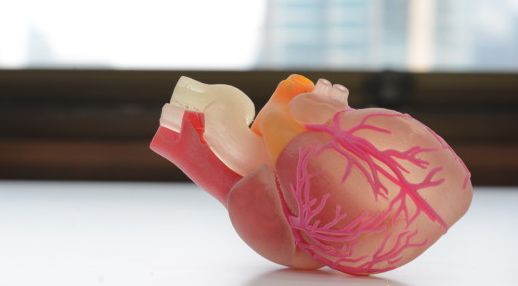

Since spun off from the world-leading Swiss Federal Institute of Technology (ETH Zurich) in 2018, Spectroplast AG has been focusing on the development and application of silicone-based 3D printing technology. The company uses patented silicone additive manufacturing (SAM) technology to provide customized 3D printing solutions for multiple industries, especially in areas with strict requirements for biocompatibility. Spectroplast emphasizes that products printed with TrueSil resin are no different in quality and performance from traditional injection molded products. This printing technology is particularly suitable for parts with a production volume of 1 to 50,000 pieces, providing an efficient and cost-effective alternative for small-batch production.

Spectroplast plans to use the newly acquired funds to expand the scope of technology applications and enhance its support capabilities for existing customers. Considering that China is the world's largest exporter of silicone and the United States is the fastest growing export market, the increase in trade tensions between the world's two largest economies may stimulate interest in 3D printing silicone applications.

Dr. Florian Bechmann, Chief Technology Officer of the HZG Group, said: “With Spectroplast, silicone is becoming the premium polymer for the 3D printing industry. We are confident in this application direction and the expertise of the management team and will continue to exploit the many positive material properties of silicone in 3D printing. This is due to the high biocompatibility of silicone’s chemical structure and its extreme resistance to environmental influences and temperature changes.”

The rise of silicone in additive manufacturing

With the continuous advancement of industrial automation and intelligent manufacturing, the application of silicone materials in the additive manufacturing industry has become increasingly important. In factory workshop maintenance and robotics, silicone has become an indispensable material due to its unique physical properties and is widely used in gaskets, seals, and robot grippers. As technology evolves, the demand for silicone is expected to continue to grow, thereby promoting the use of this material in the manufacturing industry.

Although 3D printing silicone technology is still in its relatively early stages, innovator Spectroplast has secured the backing of two venture capital firms with deep knowledge in the AM industry, giving it a unique market advantage to capture upcoming industry growth opportunities.

In addition to strong performance in dental, hearing aids and industrial applications, the wearable electronics market is likely to be a key driver of future growth in the silicone 3D printing sector. As the electronics supply chain is extremely sensitive to geopolitical changes that could lead to trade disruptions, this market has the potential to be a major catalyst for new activity in silicone 3D printing, driving industry growth over the next decade.