Wide hardness coverage: By changing the distribution of each reaction group of TPU, products with different hardness can be obtained, and with the increase of hardness, the product can still maintain stable ductility and wear resistance.

High impact toughness: TPU products have outstanding bearing capacity, impact resistance and shock absorption performance, and are resistant to acid and alkali, moisture, bacteria and yellowing.

Outstanding drought resistance: TPU has a relatively low glass transition temperature and can maintain stable ductility, hair softness and other physical properties at minus 35°C.

Good processing performance: TPU can be processed by common thermosetting material processing methods, such as injection molding, extrusion, injection molding, lamination, etc.

TPU classification: According to the soft segment structure, it can be divided into polyester type, polyether type, and butene type; according to the hard segment structure, it can be divided into urethane type and urethane urea type;

According to the production and processing methods, it can be divided into injection molding grade and extrusion grade:

1. The main products of injection molding are: various gears, hydraulic seals, sports shoe soles, ski boots, power plugs, synchronous belts, etc.

2. The main products of extrusion are: wires and cables, pipes, pulse damper waterproof membranes, etc. According to performance, they are divided into polyester and polyether.

3. Polyester type: acid and alkali resistant, wear resistant, good tensile properties, tensile strain properties, water wash resistance and high temperature resistance.

4. Polyether type: hydrolysis resistance, high toughness and high resilience, good ultra-low temperature performance. The main uses are as mentioned above. TPU materials can be widely used in shoes, electronic products, clothing, national defense products, sports goods, chemical products, baby products, civil engineering appliances and others.

Polyurethane TPU is widely used in daily necessities and industrial industries such as shoe materials, electronics, electrical equipment, industrial equipment, auto parts, pipes, wires and cables, films, etc. due to its excellent physical properties, operational performance and environmental protection performance.

Polyester TPU production process and application production and processing methods: injection molding, extrusion, injection molding, film blowing

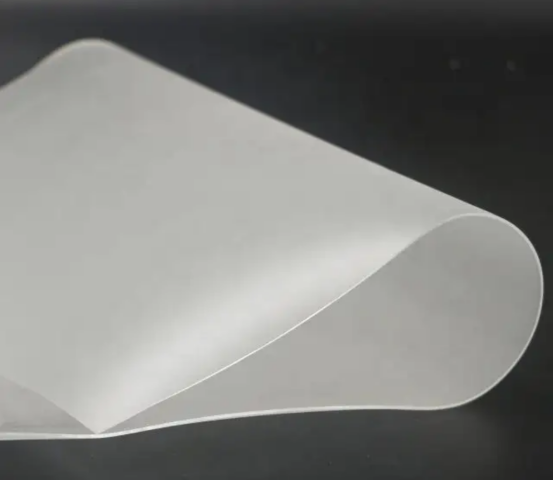

Characteristics of polyester TPU: excellent structural mechanical properties, wear resistance and non-slip, excellent ultra-low temperature toughness, excellent production and processing fluidity and rapid prototyping technology, low and high temperature resistance, good clarity, stable extrusion performance, and stable melting point.

Polyester TPU applications: sole parts, plastic packaging, blended modified materials, spare parts, mobile phone cases, injection molding wheels, sports protective gear and machinery manufacturing; films, pipes, wires and cables, conveyor belts, elastic cords, straps, air cushions, shoe trims.

Thermoplastic polyurethane elastomer, commonly known as TPU, is a linear block prepolymer composed of an oligomer polyether polyol soft segment and a diisocyanate-chain extender hard segment.

To put it simply, elastomer refers to a fiber material with a glass transition temperature lower than room temperature, a tensile strength of >50%, and good recovery after the external force is removed. Polyurethane elastomer is a relatively unique type of elastomer; polyurethane elastomer has a wide range of hardness and a wide range of performance. Therefore, polyurethane elastomer is a type of fiber material between vulcanized rubber and plastic.