Due to the hardness and brittleness of ceramic materials, the preparation of via holes, cutting or dicing is very difficult. Traditional mechanical processing methods are time-consuming and labor-intensive, and there is stress during the processing, which can easily damage the substrate. As a flexible, efficient and high-yield processing method, laser has shown extraordinary capabilities in the processing of ceramic substrates.

1. Advantages of laser technology

Laser is an advanced processing technology with non-contact processing, no tool wear, high precision and high flexibility. It has the advantages of high precision, high efficiency and controllability, small heat-affected zone, no cutting force, and no "tool" wear. It has become one of the most ideal means of ceramic processing today.

1) The laser cutting head will not contact the material surface and will not scratch the workpiece.

2) The cutting gap is narrow, saving materials;

3) Small laser spot, high energy density, high precision, fast speed, high stability of line width and depth;

4) Laser processing is fine, and the cutting surface is smooth and burr-free;

5) The heat-affected zone is small, the local deformation of the workpiece is minimal, and there is no mechanical deformation. Ceramic substrates are easy to break and have high requirements for process technology, so laser drilling is often used. It has the characteristics of precision, speed, and efficiency, can be used for large-scale and batch drilling, and has no tool loss, which meets the requirements of high-density interconnection and fine development of ceramic substrates;

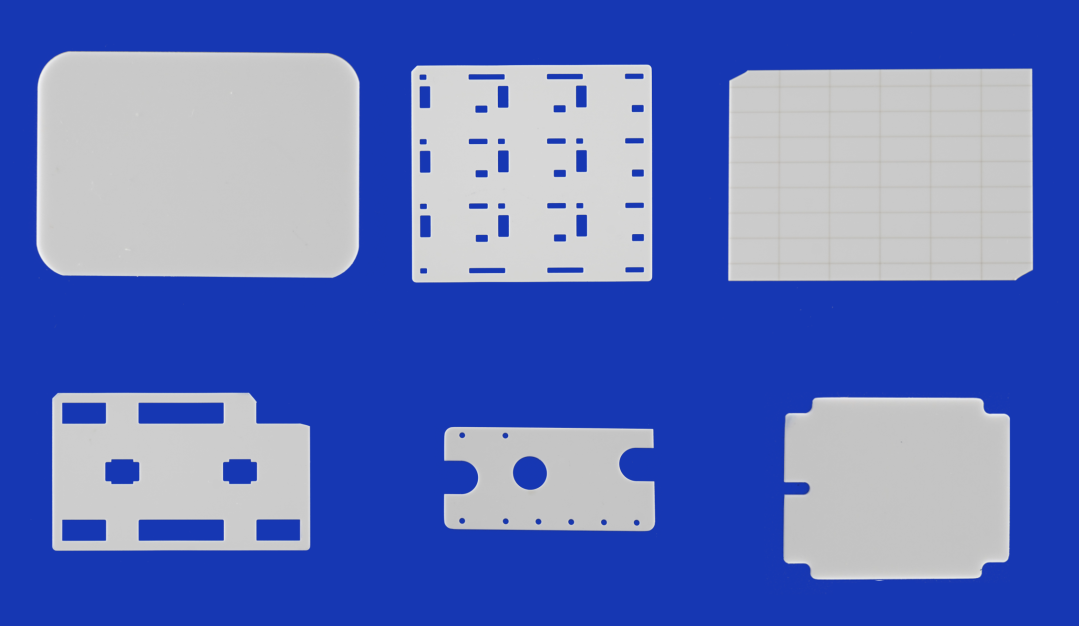

6) Good processing flexibility, can process any graphics, and can cut special-shaped materials.

2. Application of laser in ceramic substrate

Laser processing has long been a mainstream application in the processing of various ceramic substrates. At present, laser processing equipment for ceramic substrates is mainly used for cutting, scribing and laser drilling.

1) Laser scribing/cutting

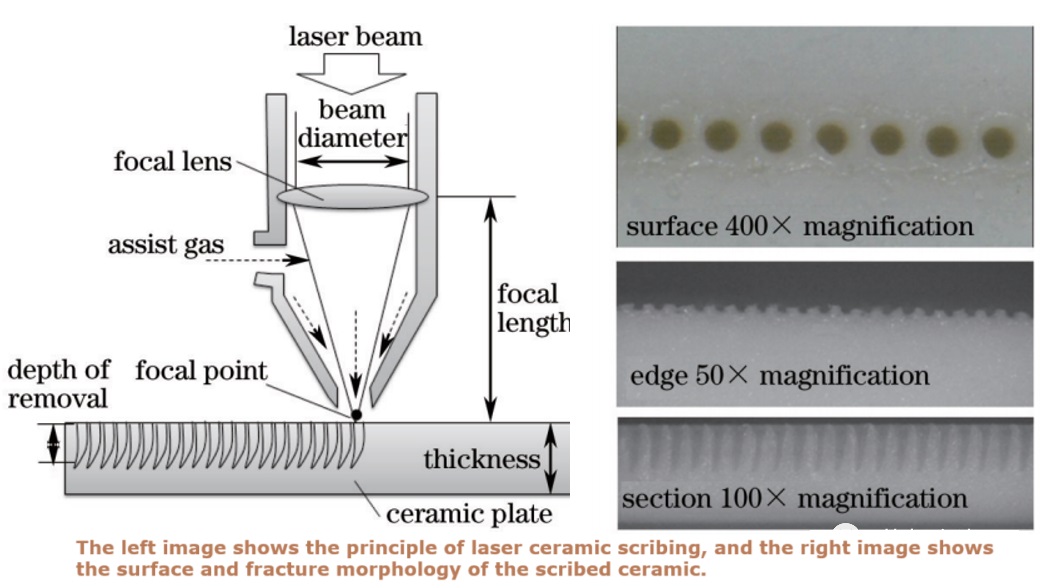

Laser scribing is also called scratch cutting or controlled fracture cutting. Its mechanism is that the laser beam is focused on the surface of the ceramic substrate through the light guide system, an exothermic reaction occurs to generate high temperature, ablate, melt and vaporize the ceramic scribing area, and form interconnected blind holes (grooves) on the ceramic surface. If stress is applied along the scribing area, due to stress concentration, the material can easily break accurately along the scribing line to complete the slicing. Laser scribing is also widely used in the scribing process of ceramic substrates after sintering. Scribing is to form lines by burning continuous and densely arranged dot-shaped pits on the ceramic surface through laser, so as to facilitate the division into independent small units after packaging.

2) Laser drilling

Drilling is the most widely used process processing method for laser in the production process of HTCC, LTCC and DPC. Use a laser drilling machine to open up the upper and lower substrates as a path for connecting the upper and lower board surfaces, realize the vertical interconnection of the upper/lower surfaces of the ceramic substrate, and realize the three-dimensional packaging and integration of electronic devices.

Laser drilling machines use infrared, green, ultraviolet, CO2 and other laser beams of different wavelengths to irradiate the surface of the material for different ceramic materials. Each time a laser pulse is emitted, a portion of the material is burned off. Compared with mechanical drilling, laser drilling has many advantages, including higher processing accuracy, lower consumables cost, and higher product flexibility.

With the continuous development of the microelectronics industry, electronic components are gradually moving towards miniaturization and thinness, and the requirements for precision are becoming higher and higher. This is bound to put higher and higher requirements on the processing degree of ceramic substrates, and laser technology has great potential.