Overmolding is an operation in which two or more mediums (substances) are merged to form an end-molded product. Plastic overmolding needs to make two separate molds: one is the substrate (first mold), and the second mold is called the overmold (usually a TPE material for the second mold). If the substrate is metal or brass, this type of overmolding is normally called insert molding, and insert molding only needs one mold to finish the process.

The plastic overmolded materials most commonly used are thermoplastics (TPE) and rubber, or the same material but different colors. During overmolding, the activity that happens is either mechanical or chemical, which leaves the two substances bonded.

The overmolding process involves producing the molded part (substrate) from the first mold and moving it to another related overmold. The substance can be used to combine the surface molded with the molding substrate. Otherwise, the molded material can be put back on the surface from which it was extracted, and the overmolded substance can be added. Types of over molding include two-shot sequential over molding, insert over molding, and multi-shot injection molding.

In two-shot sequential plastic overmolding, the molding machine injects the first plastic resin into the first mold cavity (both molds in one machine), moves the molded part to the second overmold immediately, closes the mold, and injects the second material, using the first component as an insert for the second shot using a different material or color. This process requires a special injection machine with two injection units.

Insert over-molding uses a pre-molded insert placed into the mold before injecting the second material; if the inserts are metal or brass, then we call it metal insert molding. This over-molding process, which we used a lot, involves multi-shot injection molding, which injects multiple plastic resins into the mold cavity during the same injection molding cycle.

Overmolding can be broken down into 3 types: Insert Molding, Overmolding, Co-injection Molding.

The Versatility of Overmolding

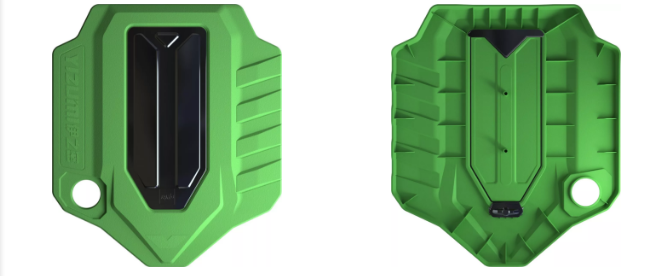

The options created by overmolding are endless. Overmolding can be added to change the surface of a part or product component by adding textures, colors, and incorporating functional components desired by specific consumers. Overmolding physically changes the surface of a part or product, so it can be made smooth or rough depending on the material used for overmolding. The materials used for overmolding have a wide range of options for strength, flexibility, and durability.

Overmolding Improves Aesthetic Design and Functionality

In addition to the tactile changes overmolding offers, the options are endless when it comes to the colors that can be added to overmolding. No longer are you limited to a single color of metal. Overmolding offers an unlimited choice of colors for plastics.

Streamlining Product Manufacturing with Overmolding

Overmolding can also simplify products by reducing the need for seals. With overmolding, seals can be incorporated and adhered directly to the part, reducing the number of overall pieces required for the product. Plastic seals can be affixed directly to the part to ensure a clean, leak-free connection.

Lanxin Co., Ltd. is a one-stop service provider that integrates precision injection mold design, manufacturing, injection molding, etc. We are happy to share with you our understanding of plastic injection molding and provide you with economical plastic injection molding solutions.