Die-cutting moulds are crucial tools for manufacturers of insulating materials , used to punch and produce finished products. Die-cutting moulds play a crucial role in the stamping process, directly impacting die-cutting quality and craftsmanship. Let Lanxin share some basic knowledge about die-cutting moulds.

To know the die cutting mold/mould/tool

Die cutting moulds: There are over 100 different types of die cutting molds, based on the angle of the blade, the hardness of the blade, the texture of the blade, and the surface processing of the blade. The following are the most common and commonly used molds:

1. Aluminum alloy mold

2. Etching mold

3. Aluminum plate mold

4. Plastic cutting mold

5. Laser cutting mold

6. Hardware mold, QDC composite mold

7. Circular blade roller mold and hot stamping, concave and convex molds, etc.

Development and production of die cutting molds

The development and production of die cutters are based on a deep understanding of the client's product requirements and a thorough knowledge of the materials used. All the client's desired information is reflected in the design drawing. Therefore, it's essential to first review the drawing and translate the client's requirements into their own process flow. To visualize the final product and design the production process, engineers must possess a thorough understanding of the materials used and, crucially, a good understanding of the company's machine capabilities.

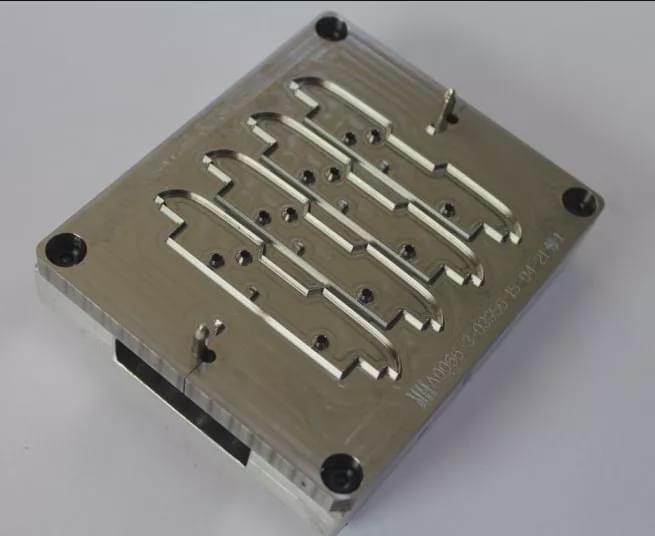

Nowadays, one of the more popular die cutting molds is the etching mold . It is made by exposing the film and steel plate together, then developing and reinforcing it, and then etching away the excess parts with an etching machine. Finally, an imported CNC engraving machine is used to process the blade into shape and then perform surface treatment to form a stamping die cutting mold. The die cutting mold produced by Lanxin Company has a tolerance of plus or minus 0.05mm, which meets the requirements of this industry standard. The height difference of the die cutting can be selected according to the properties of the material, and the blade angle can also be changed from 25° to 55° according to requirements. It can also produce a single-edged blade with an inner bevel and an outer straight or inner straight and an outer bevel effect.

Engraving molds are commonly used in the die-cutting industry, typically used to stamp out the desired shape of die-cut products with high precision. ( Lanxin 's engraving molds are made from internationally certified high-quality steel, formed in a single operation with no joints. High-precision high-low cutters, dotted line cutters, and spring-loaded block cutters can also be produced from the same mold. Engraving molds offer high dimensional accuracy, with tolerances up to +/- 0.03mm, and a minimum double-blade position of 0.5mm. They can process angles ranging from 30°to 60°, and can also be used for blanking and waste removal, saving labor and improving production efficiency. They are referred to as blanking molds, waste collection molds, waste removal molds, and waste removal molds.)

The above content first introduces engraving mold and etching mold, and then we will continue other types later.