Product description

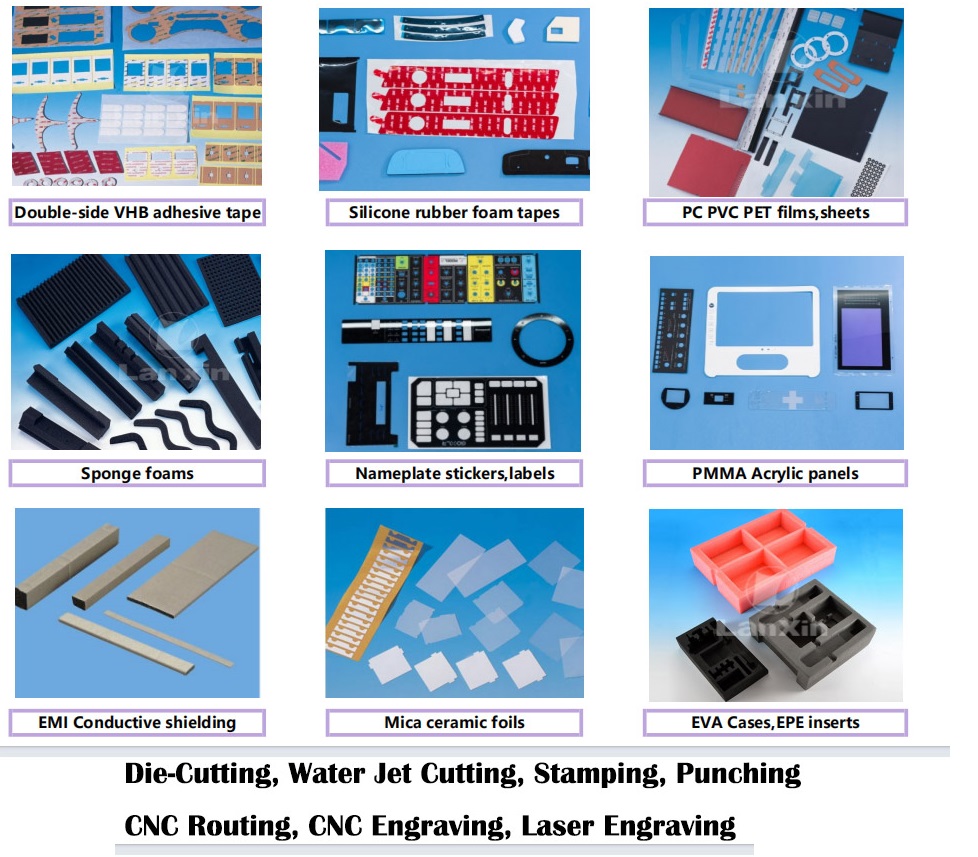

Many of the die-cutting materials we work with are already used in a variety of industries:

| ITEM | EVA Foam Sealing | ||

| Material | Die-Cutting materials can improve efficiency and output quality. Here are just a few of the materials that we can die-cut:

|

| Certificate | IATF 16949:2016 / ISO 9001:2015 / ISO 45001:2018 / ISO 14001:2015 /REACH/ROHS/MSDS/LFGB/F D A |

| Drawing Format | .stp / .step / .igs /.stl /.dwg / .pdf |

| Cutting types | Rotary die-cutting, flatbed die-cutting, waterjet cutting, CNC, etc... |

EVA closed cell foam is used in a variety of industrial and commercial gasket and sealing applications. A lightweight and odorless material, EVA foam exhibits good mechanical strength, excellent chemical resistance, high buoyancy, low water absorption, and good acoustic properties. Lanxin company is a leading gasket manufacturer to a broad national and international customer base. EVA foam gasket is available at Lanxin along with a wide range of other rubber gasket and sealing materials. Our gasket engineering department welcomes the opportunity to help you select the best material for your custom die-cutting gaskets and seals.

EVA Foam Gaskets & Seals by Lanxin company are versatile and highly functional, finding extensive use across multiple sectors. In the construction industry, they are applied to windows and doors, effectively weatherproofing structures by blocking out rain, wind, and dust, and enhancing energy efficiency by preventing air leakage. In the automotive field, eva foam gaskets reduce noise, vibration, and harshness (NVH), creating a quieter and more comfortable driving environment. For electronic devices, these seals act as shock-absorbing buffers, safeguarding delicate components from impacts during transportation and daily use. Meanwhile, eva silicone foam gaskets are ideal for anti-slip and insulating purposes in electrical appliances, ensuring safety and stability during operation.

Lanxin's expertise in eva foam gaskets and seals sets it apart. With advanced manufacturing facilities, we can produce gaskets and seals with precise dimensions, ensuring a perfect fit for various applications. Our R&D team continuously innovates material formulations to improve properties like resilience, durability, and chemical resistance. Rigorous quality control processes guarantee that each product meets or exceeds industry standards, providing customers with reliable eva foam gaskets and seals solutions.

Images for reference

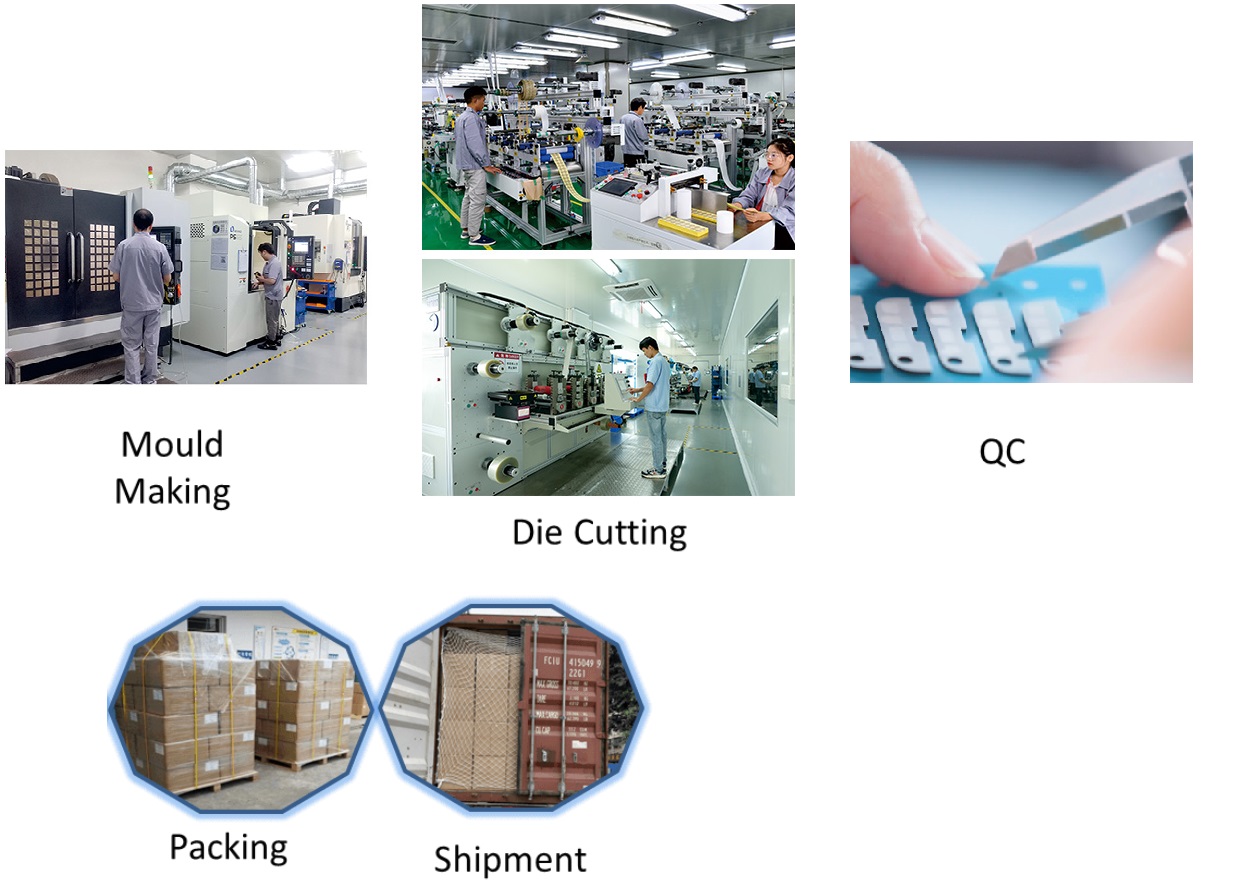

Producing Process

Quality standard

Lanxin's insulation materials quality is 100% according to ISO9001 Standard. We seriously take care of the quality control from IQC to OQC, throughout each step of the production.

Lanxin dedicated to strict quality control and thoughtful customer service. We strive to exceed our customers' expectation in all aspects of product manufacturing process, and recognize our great responsibilities to our customers.