Two shot injection molding, or 2K injection molding, is a manufacturing process used to mold two colors or materials into one plastic. This plastic molding technology blends two materials or two different material colors into one plastic part by using 2k injection molding machine.The chemical bonding process involved in this process is very important because they are capable to combine 2 or more material into one part. When using 2K injection molding technology process, the material selection will be the important point factor to the success of the project or not.

Working principle of two-color injection molding

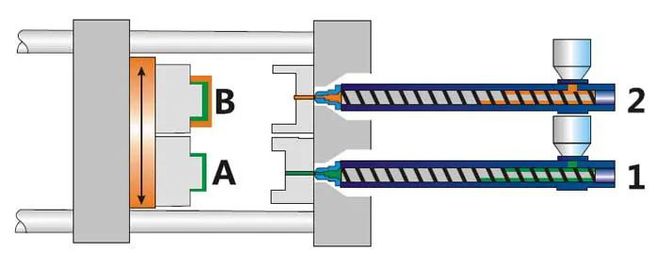

Two-color injection molding requires a male mold and two female molds. The first injection is in the male mold and the first female mold. After molding, the mold is opened and the second female mold is directly switched without demolding for the second injection. After demolding, the two-color injection finished product can be obtained.

two-color injection molding machine diagram

What are the advantages of two-color injection molding?

●Reduce material costs/environmental protection

●Enhanced performance

●Improve efficiency and reduce costs

●Long mold life, stable quality, and reduced scrap rate

●Free design, beautiful appearance

According to different usage characteristics, the core and skin can freely choose materials, no assembly is required, and seams are reduced, solving the problem that some products cannot be mass-produced due to special structures.

Requirements for materials, processes and molds for two-color injection molding

1. Material requirements

The paired materials for two-color injection molding must meet two basic compatibility conditions, namely, bonding compatibility and processing compatibility.

2. Process requirements

--Soft and hard glue double shot design-——

There must be a certain temperature difference between the melting points of the two materials. It is generally recommended to be 60°C, and it is recommended to be at least 30°C. The melting point of the first shot material is high. Generally, the first shot is PC or PC/ABS, and the second shot is TPU or TPE. The thickness of PC is 0.6-0.7mm, and the thickness of software is 0.4mm or more.

Try to widen the contact area, make grooves to increase adhesion, or use core pulling for the first shot, inject part of the material of the second shot into the first shot, and make the surface of the first shot mold as rough as possible.

--Transparent and non-transparent double shot design——

Double-shot design for small lenses : the first shot is for non-transparent ones, and the second shot is for lenses. Try to use PC with a high melting point for the first shot, and PMMA for the second shot.

Transparent and non-transparent double shot design for decoration: the first shot is non-transparent material, the second shot is transparent material. Non-transparent material is usually PC with high material temperature, and the second shot transparent material is PMMA or PC. PC needs to be sprayed with UV for protection, PMMA can choose UV or strengthening, and UV must be selected if there are characters on the surface.

Requirements for mold

1. The two shapes of the female mold must be different, each molding a product, while the two shapes of the male mold must be exactly the same;

2. The front and rear molds of the mold must match after rotating 180° around the center;

3. Carefully check the maximum mold thickness, minimum mold thickness, KO hole distance, etc.

4. The nozzle of the three-plate mold should be designed to be able to automatically demould;

5. When designing the second injection mold, in order to prevent the second mold from scratching the glue position of the first molded product, a part of the gap can be designed. However, the strength of each glue sealing position must be carefully considered;

6. During injection molding, the size of the product molded by the first injection molding can be slightly larger so that it can be pressed more tightly with the other male mold during the second molding to achieve the effect of sealing;

7. Pay attention to whether the flow of plastic will impact the first molded product and cause deformation of the glue position during the second injection molding.

8. Before closing the A and B plates, pay attention to whether the front mold slider or inclined top will reset first and crush the product;

9. The water supply arrangement of the two female molds and the male mold should be as sufficient and balanced as possible;

10. In 99% of cases, the hard plastic part of the product is injected first, and then the soft plastic part of the product is injected, because the soft plastic is easy to deform.

Main Applications

The two-color injection molding process is now widely used in almost all plastic fields such as automobiles, electronic products, power tools, medical products, home appliances, toys, etc.

Let’s showcase two-color process products from several fields.

3C

Automobile series

Daily use

Hardware structural parts