The more complex the plastic part, the more complex the molding process. This affects time to market, cost, and repeatability. Today, we will introduce the differences between two-color mold injection molding and ordinary injection molding. And why we should choose two-color mold injection molding.

What is two-color injection molding?

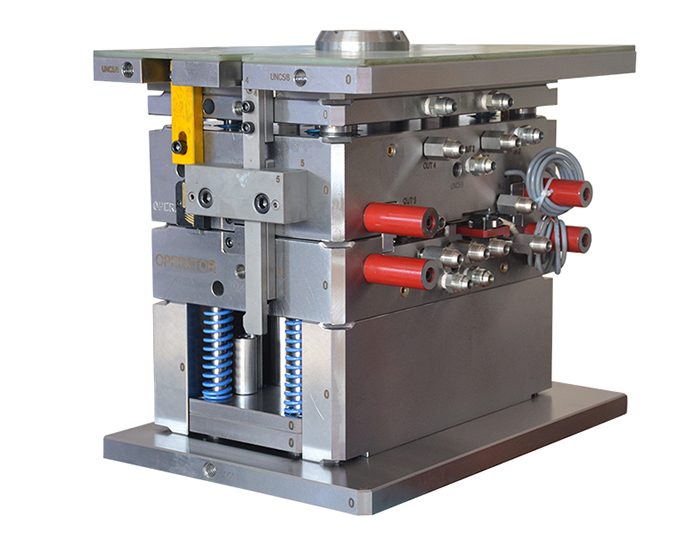

Two-color mold injection molding is an effective and efficient method to mold plastic parts with multiple colors, materials or complex designs in one mold and one machine. Two-color mold injection molding can help you achieve market differentiation while increasing the functionality of your application.

1. Reduce time and labor

Traditional overmolding increases production time and manual labor. Traditionally, products with multiple materials are produced using multiple molds and multiple machines. Part of the product is molded in one machine, cooled, and then overmolded in a second machine. This process results in two separate cycle times, increased labor, and multiple quality and validation inspections. Two-shot mold injection molding eliminates these secondary operations, thereby reducing time to market and overall labor costs.

2. Cost-effectiveness

Total costs are reduced due to savings in manual labor and simplified process handling. The main reason for the cost reduction is the elimination of secondary operations, which reduces the manual labor associated with maintaining and running additional machines, factory space and time.

3. Controlled repeatability and consistency

The ability to make an exact replica every time you inject it on any machine depends on a scientifically controlled process. Since both components are made on one mold and one machine, every step of two-color mold injection molding is precisely controlled and monitored. With traditional overmolding, quality and repeatability are not easily controlled or scientifically tracked, resulting in minor variations and imperfections in each manufactured product. Two-color mold injection molding ensures that every finished product manufactured is of high repeatability and quality.

4. Compatibility/Material Selection

The right material selection ensures secure and quality attachment of components. Using multiple colors and materials is also advantageous, especially when choosing a marketing strategy as a consumer product. Using two non-bonding materials in a specially designed mold allows parts to be molded together.

5. New design possibilities

—Multiple colors, materials and ingredients

—Increase operating space possible

How are the plastic products with multiple colors that we see made? For multiple colors, both two-color injection molding and two-shot injection molding can produce such products, so what is the difference between two-color mold injection molding and two-shot injection molding?

1. Two-color injection molding is also called two-color mold injection molding. It is to inject two plastic materials on the same injection molding machine. The molding is divided into two steps, but the product is only molded once. It is usually completed by a set of molds and requires a special two-color injection molding machine.

Two-color injection molding: True two-color mold, the product is rotated 180 degrees after one material is brewed, and then another material is brewed, that is: the same rear mold, different front mold. High efficiency, low cost when the quantity is large. If there is a requirement for production capacity, do not consider secondary injection molding, which has low efficiency and high defective rate.

2. Secondary injection molding is also called overmolding. It is two plastic materials that are not necessarily injected on the same injection molding machine. They are molded twice. After the product is taken out of one mold, it is put into another mold for the second injection molding. Therefore, this molding process is usually completed by two sets of molds, and no special two-color injection molding machine is required.

Secondary injection molding is to first make a colored plastic part on the first single-color injection molding machine, and then manually put this product into the second mold for molding. Because it is difficult to place it accurately by hand, the product will have surface quality problems such as burrs, scratches, and breakages after it comes out, and the amount of scrap is very high.

The above is the analysis of the difference between two-color mold injection molding and secondary injection molding introduced by Lanxin Industry . I hope it can provide a reference for you. Two-color injection molding is not only a simple combination of two or more colors of plastics, but also has better performance in product precision, beautiful appearance, and different colors of plastics.