As a special adhesive, pressure-sensitive adhesive has the characteristics of high adhesion and tearability. It is currently widely used in various fields such as medical, electronics, communications, automobiles, construction, packaging, etc. Compared with other adhesives, it has many excellent properties. Do you really understand pressure-sensitive adhesive? How does it work? What are its characteristics? Now let’s know pressure-sensitive adhesive.

1. What is pressure-sensitive adhesive?

Pressure sensitive adhesive, abbreviated as PSA, is a type of pressure-sensitive adhesive film material. The construction can be completed by applying pressure by hand (of course, it can also be completed with equipment such as rollers). It does not require auxiliary curing such as heating, catalysts or UV light irradiation, and has long-lasting adhesion, cohesion and viscoelasticity.

2. Working Principle of Pressure-Sensitive Adhesive

Pressure sensitive adhesives, as the name implies, require pressure to adhere to the substrate. This is why applying the right amount of pressure is so important to achieve good adhesion. In simple terms, the adhesive needs to flow and fully contact the bonded substrate and interact with the substrate. Over time, the PSA gains strength by further wetting the substrate. The adhesive will enter the micropores and gaps on the surface of the substrate as the bubbles are discharged. In order to achieve high peel strength, the adhesive on the tape must not only adhere to the substrate, but also have viscoelastic properties.

3. Characteristics of pressure-sensitive adhesive

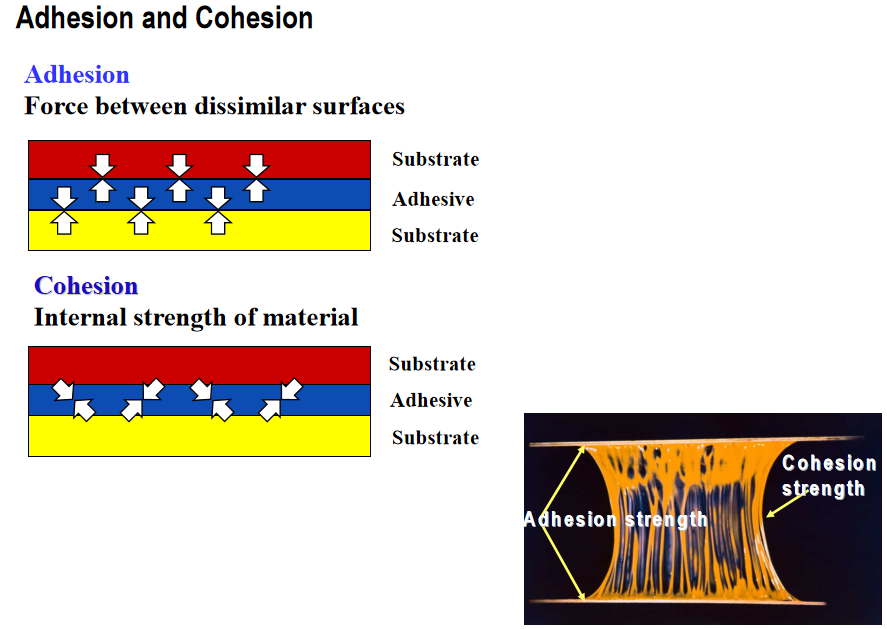

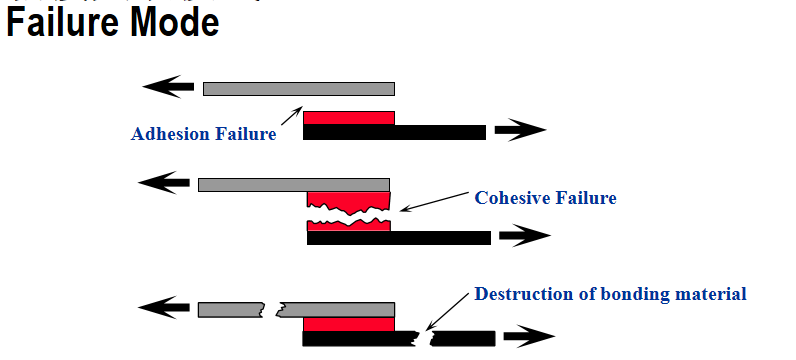

When measuring the performance of a pressure-sensitive adhesive, we usually look at two forces first: adhesion and cohesion.

Corresponding to these two forces, the adhesive force is the stickiness between the tape and the adhered object, and we usually use the peel force to measure the adhesive force. The cohesive force reflects the bonding force between the molecular chains of the tape itself, which is usually verified by the static suspension method and measured by the shear force test. In addition to these two basic ones, according to different characteristics, we will also test initial adhesion, thermal conductivity, electrical conductivity, insulation performance, tensile strength, light transmittance, flame retardancy, low volatility, etc., as well as more specific customer requirements, such as high temperature and humidity, thermal shock and other aging test requirements.

4. Classification of pressure-sensitive adhesives

Most pressure-sensitive adhesives are suitable for plastic, fabric or paper surfaces. These tapes are either single-sided or double-sided. The main disadvantage of most PSA is their relatively low bond strength and lack of creep resistance. Therefore, they are not suitable for structural bonding. However, in recent years, some high-bond strength double-sided tapes have been developed for semi-structural bonding applications. The VHB tape is one of them, usually coated on a foam carrier to improve adhesion to rough surfaces, contours and seam areas.

Pressure sensitive adhesives are divided into three main categories based on their chemical composition, and of course there are many modified and mixed applications within each type. There are also some others such as PU polyurethane, thermoplastic elastomer, etc. Below is a brief description of the main types of PSA and some usage guidelines.

According to the product structure, it can be divided into single-sided adhesive and double-sided adhesive. Single-sided adhesive contains at least one layer of substrate and one layer of adhesive film, such as common labels. The substrate can be a variety of materials, such as PET polyester, PI polyimide, copper foil, aluminum foil, conductive cloth, etc.

Double-sided adhesive can be a pure adhesive film or a three-layer structure, containing at least two layers of adhesive, with a substrate layer in the middle of the adhesive film layer. The substrate can also be diversified. With the addition of different substrates, different functions can be achieved, such as thermal conductivity, electrical conductivity, shielding, etc.

Continue Next......