Mica products are mainly used as thermal runaway protection materials for power batteries in the new energy vehicle industry. In recent years, with the rapid development of the global new energy vehicle industry, the performance of power batteries, as core components of new energy vehicles, has been continuously improved, and the overall trend is that battery energy density will gradually increase. Mica sheets are widely used, easy to process, and high-performance thermal interface materials(TIMs), and are valued by mainstream car companies and power battery manufacturers.

Mica is commonly found in transparent or translucent flakes. The flakes are elastic and tough, and can remain stable in high temperature, strong acid and alkali environments. With its unique crystal structure and physical and chemical properties, mica is widely used in many fields.

In the field of electrical and electronic engineering, mica has become an important raw material for manufacturing electrical equipment due to its high insulation, good thermal conductivity and chemical stability. Common products include mica tapes and mica sheets, which are also gradually used in the manufacture of electronic components. In the field of new energy, mica sheets can be used as packaging components for solar panels to improve stability and life, and can also be used to manufacture battery separators to enhance battery performance and safety. In addition, in the field of aerospace, composite materials prepared from mica are used in aerospace equipment, and nano-scale mica materials are used to manufacture high-precision electronic devices and sensors.

In the new energy vehicle industry, as the performance of power batteries improves and energy density gradually increases, thermal runaway protection is extremely important. At present, new energy vehicle manufacturers use aerogel felt, flame retardant foam, mica materials, ceramic silicone rubber, etc. as power battery thermal runaway protection materials.

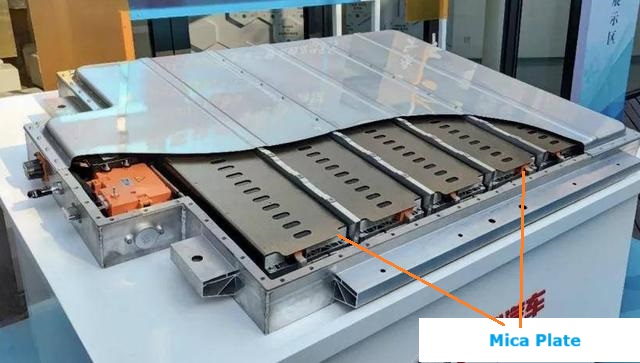

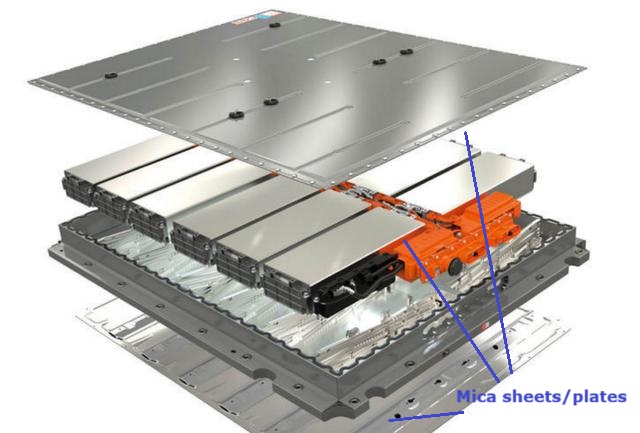

In terms of power battery cell protection, it is mainly achieved by isolating heat transfer between cells (such as using mica materials, aerogels, composite foams, etc.), enhancing the battery's ability to quickly dissipate heat (such as graphene composite materials, phase change heat-absorbing materials, etc.), building a battery self-protection mechanism (fuse mechanism, battery pressure relief valve), and using potting glue to reduce heat transfer (soft pack module). In terms of battery PACK protection, mica materials are widely used. Usually, a shielding isolation layer composed of mica sheets is added between the battery module cells to play a thermal isolation role. The opening position can be designed according to the pressure opening method. In the event of thermal runaway, it can keep high-temperature smoke away from the damaged area and accelerate the diffusion of high-temperature combustible gases and heat.

Mica materials are generally processed into mica sheets for use, which have many advantages. It can still maintain good insulation properties in high temperature environments of 500℃ - 1200℃, has good bending strength and hardness, is acid and alkali resistant, aging resistant, can be processed into various shapes, and does not produce toxic gases at high temperatures. Mica materials have a long history of application in battery thermal runaway protection, and the solution is mature and has been adopted by many companies. At present, it is mainly used between modules and between modules and battery covers. With the development of the trend of non-moduleization, it will be more used in the future for thermal runaway protection between battery cells and battery covers.

According to the calculation of Gaogong Industry Research Institute (GGII), the area of flame retardant and heat insulation materials used in the upper cover plate and battery module of new energy vehicle power battery packs in 2022 will be 6.75 million square meters and 6.71 million square meters respectively, of which mica materials account for 83% and 30% respectively; it is expected that in 2025, the area of flame retardant and heat insulation materials used in these two parts will reach 14.99 million square meters and 11.7 million square meters respectively, and the proportion of mica materials will increase to 80% and 45% respectively. According to Frost & Sullivan's research, the global new energy vehicle mica material market size has an average annual compound growth rate of 86.40% from 2017 to 2022; the average annual compound growth rate from 2023 to 2027 is expected to be 37.60%, and the market size in 2027 will be about US$ 1.5 billion . With the advancement of science and technology, new uses of mica materials are constantly being explored, and the application prospects in new energy vehicle batteries and other fields will be broader.