The large-scale application of mica sheets, mica boards, mica tapes and other mica products is attributed to the vigorous development of new energy and energy storage industries in recent years. The following discusses the application of mica products in the field of solar energy and new energy.

1. Application of mica materials in solar panels

(I) Enhanced light absorption

1. Physical properties and basis of light absorption: Mica is a mineral composed of silicate and aluminate, with a layered crystal structure. This structure gives it high thermal stability, excellent chemical stability and good light transmittance. Under the action of light, mica can effectively absorb and reflect light, with part of the light being absorbed and part being reflected, making it an ideal material for the surface coating of solar panels.

2. Application effect: As the outer layer of solar panels, mica sheets can significantly improve the light absorption rate of silicon wafers. It can capture light in a wider spectrum range and guide it to the surface of the silicon wafer, improving light capture and utilization efficiency. At the same time, mica sheets can also optimize reflectivity, so that part of the reflected light returns to the silicon wafer, increasing the propagation path and residence time of light in the silicon wafer, thereby improving the photoelectric conversion efficiency of solar panels and improving energy utilization efficiency.

(II) Packaging and heat dissipation

1. Packaging materials: Mica sheets made of materials such as biotite and phlogopite are used for the packaging of solar panels. Its main function is to protect the battery module from environmental factors such as moisture, dust, and ultraviolet rays, and extend the service life of the battery panel.

2. Optimization of heat dissipation performance: The high thermal conductivity of mica sheets can conduct the heat generated inside the battery cell to the heat sink or shell, preventing local overheating and improving the overall stability and efficiency of the battery pack. Different types of mica sheets have their own advantages in application. Biotite sheets have the best conductivity and are suitable for high-efficiency battery pack packaging; phlogopite sheets have excellent high temperature resistance and are suitable for operation in high temperature environments; sericite and pearl mica sheets are also used, but their performance is relatively weak. In addition, mica packaging materials can also resist the performance degradation (PID effect) of battery modules caused by temperature changes to a certain extent.

2. Application of mica products in other fields

(I) New energy vehicles

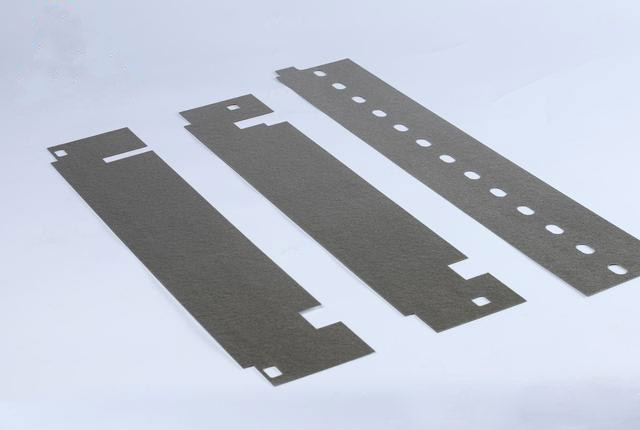

In new energy vehicle battery systems, mica sheets can be used as insulation materials and filling layers of battery separators to enhance battery safety and stability. At the same time, mica sheets can build a thermal runaway protection system to ensure the safety of the entire battery pack under extreme conditions.

(II) Battery energy storage

In the field of battery energy storage, mica sheets, with their excellent high temperature insulation performance, are used to protect against thermal runaway in key areas such as between battery modules and between modules and battery covers. Mica tape is used for insulation and fixed protection of batteries to improve battery reliability and safety.

(III) Electronics industry

In the electronics industry, mica sheets can be used to make conductive filling pads for electronic components such as circuit boards and sensors, providing good conductivity. Mica products can also be used to make electrical equipment such as capacitors, cables, and transformers to improve equipment performance and service life.

Mica, with its unique physical and chemical properties, plays an important role in solar panels, new energy vehicles, battery energy storage, electronics industry and other fields, and has broad application prospects. With the development of technology, the application of mica in various fields is expected to be further expanded and deepened.