Silicone 3D printing is a major breakthrough in additive manufacturing, and the new technology has generated great interest in the 3D printing industry because silicone materials cannot be melted by heating and deposited layer by layer like polymers or metals. New developments in silicone 3D printing, especially in the field of medical and medical biomaterials, are helping to improve the outcomes of existing treatments for patients.

Silicone 3D printing is expected to have a significant impact on the industry and represents a major milestone in the development of 3D technology. According to a study by Precision Business Insight, the silicone 3D printing market is expected to grow at a compound annual growth rate of 19.9% by 2028 , reaching $1.59 billion in 2021. This growth will also be driven by new silicone-compatible solutions offered by 3D printing companies.

Silicone: What is it and how is it made?

Polysiloxanes, commonly known as silicones, are inorganic polymers formed by the polymerization of siloxanes (molecules composed of silicon and oxygen atoms). These polymers are characterized primarily by their chemical resistance and their physical and mechanical properties. Polysiloxanes and silicones are terms that refer to the same material, with the latter being more commonly used in commercial and everyday environments.

Silicone exists in various states, depending on the macromolecular structure, size and distribution of its component chains. It exists in the form of silicone oils and rubbers (used as additives, lubricants or hydraulic fluids), silicone gels (used in cosmetic prostheses or bicycle saddles) and finally as elastomers. The latter are the most commonly used type of silicone today.

The first company to develop a 3D printing system for printing silicone was ACEO, a subsidiary of German chemical giant Wacker Chemie AG. Although ACEO ceased operations in 2021, the silicone 3D printing method developed by this early pioneer is still in demand and used in various fields, including industrial products, chemicals, medicine and dentistry.

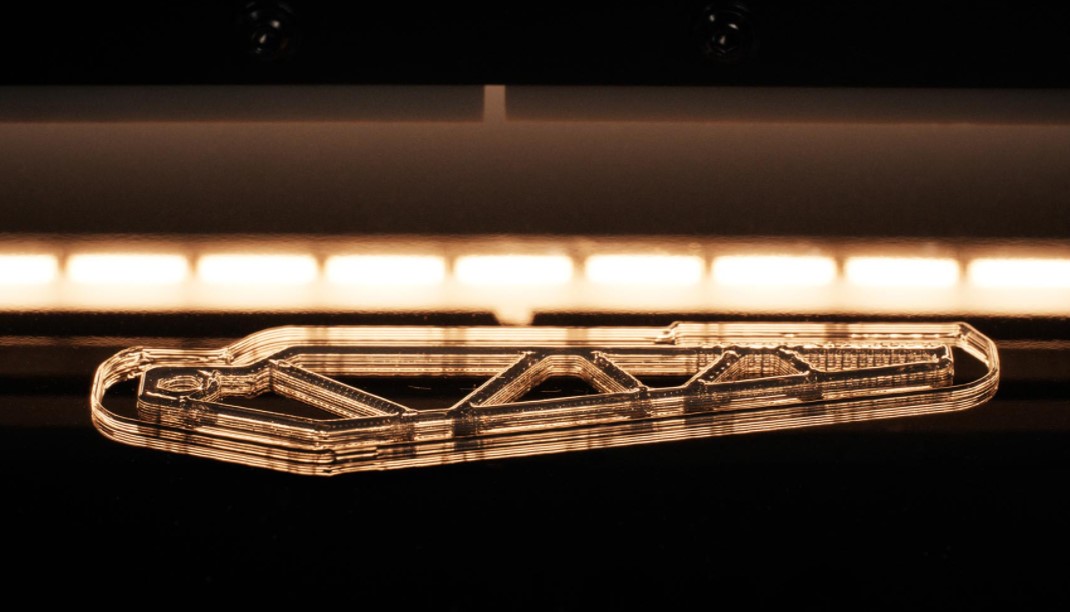

In this way, the additive manufacturing process described is similar to extrusion technology (FFF/FDM). However, the applied material is not fixed when it comes out of the nozzle, but the printed fluid is formulated to have a certain viscosity so that it can cover itself. Cross-linking reactions, in which polymers join together to form chains and form a kind of network, occur during and after the printing process and harden the material that has been formed. After cross-linking, the part acquires its final physical and chemical properties.

Advantages and limitations of silicone 3D printing

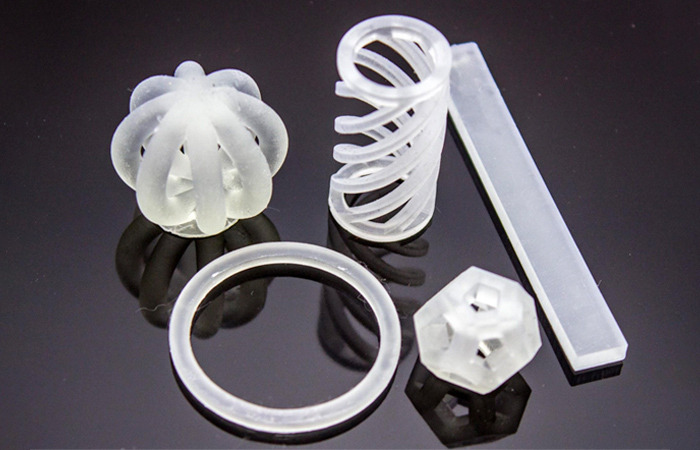

Next, let's discuss the advantages and limitations of silicone 3D printing manufacturing technology. One of the main advantages of this technology is that silicone can withstand higher loads and pressures than other materials, while saving space due to its flexibility, allowing the creation of 3D models with high flexibility and durability. Silicone can also resist extreme temperature and radiation fluctuations, making parts less susceptible to such influences than glass or similar materials.

Professionals often choose silicone when glass is considered too fragile. This is also due to its high transparency, which makes it perfect for models that require visual inspection. Finally, the combination of conductivity, insulation and biocompatibility makes silicone show great potential in various 3D printing applications, as we will see below.

One of the drawbacks of silicone 3D printing is accessibility in terms of hardware and materials. Although more and more companies are developing technical solutions for silicone 3D printing, there are still very few manufacturers offering such machines. As a result, costs are high and material selection is limited. In addition, current 3D printers have relatively low print volumes and are not ready for high-volume production. Many devices use a single print head, so they can create simple flat models without support structures for complex models. However, this has changed in recent years, with more dual-head IDEX solutions that can also produce support structures.

Applications and Manufacturers

Silicone 3D printing is ideal for small to medium-volume production, prototyping, and creating unique shapes that would be unthinkable using traditional methods. One of the industries that has benefited the most from this technology is the medical industry. In this field, silicone 3D printing is used to produce implants, prosthetics, and medical models that are customized for each patient, making it ideal for surgical procedures. Biomedical research is also taking advantage of this 3D printed silicone, using it as a scaffold for tissue engineering to create structures for cell growth for research and experimentation.

Soft robotics is another application for this form of silicone additive manufacturing. The material is particularly well suited for producing soft robotic parts, such as grippers that are able to grasp and handle delicate objects. Due to its properties, 3D printed silicone is also being explored as a viable material for flexible and stretchable electronics. Another industry that uses 3D printed silicone is consumer goods. It is primarily used to produce prototypes for flexible and stretchable clothing models and wearable devices such as smart watches.