Heat dissipation is one of the key factors to ensure the stability of equipment and extend its service life. Thermal pads are a key thermal conductive material that is widely used in electronic devices to fill the gap between heating components and radiators, thereby improving thermal efficiency and ensuring stable operation of the equipment. Traditional thermal pads usually contain silicone oil or silicone resin, while silicone-free thermal pads do not contain these ingredients and have received increasing attention and application in the electronics industry in recent years.

Definition of Silicone-free Thermal Pad

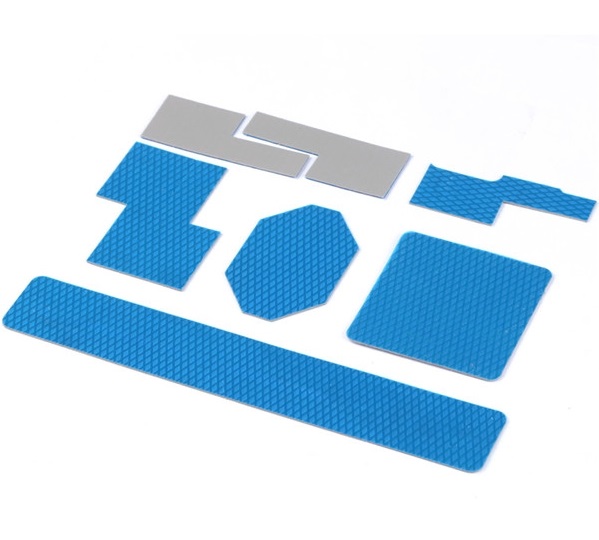

Silicone-free thermal pad, also called Non-silicone Thermal Pad is a non-silicone thermal conductive material that uses a special resin as the base material. It is made by adding metal oxides and special additives and undergoing a special process. The biggest feature of this material is that it does not volatilize siloxane and does not precipitate silicone oil, thus avoiding circuit failures and pollution problems that may be caused by traditional silicon-based materials. Therefore, non-silicone thermal pads are also called non-oil-leaking and non-polluting thermal pads, which are particularly suitable for silicon-sensitive application scenarios.

Characteristics of Silicone-free Thermal Pads

1. Does not contain silicone oil: avoids the problem of silicone oil volatilization, migration and contamination of sensitive components.

2. Good thermal conductivity: Although it does not contain silicone, the silicone-free thermal pad still has excellent thermal conductivity and can effectively conduct heat.

3. High reliability: Silicon-free materials perform well in high temperature environments, are resistant to aging and wear, and will not experience performance degradation after long-term use.

4. Environmental protection: Compared with traditional silicon-containing materials, silicon-free thermal pads are more environmentally friendly during production and use, reducing the potential harm of silicon-based compounds to the environment.

5. Low volatility and low oil yield: During long-term operation, the silicone-free thermal pad has almost no volatilization of small silicone molecules and a low oil yield, ensuring the stability and reliability of the equipment.

6. Good self-adhesion and temperature resistance: Many silicone-free thermal pads have good double-sided self-adhesion, which is easy to install and can maintain stable performance over a wide temperature range.

Material composition of silicone-free thermal pads

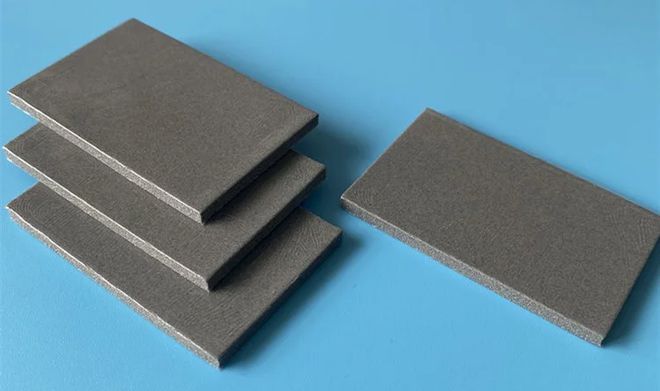

Silicone-free thermal pads are usually composed of two parts: thermal conductive filler and polymer matrix:

1. Thermally conductive fillers: Common thermally conductive fillers include boron nitride, aluminum oxide, magnesium oxide, etc. These materials have good thermal conductivity and can effectively transfer heat from the heat source to the radiator.

2. Polymer matrix: Commonly used polymer matrix materials include polyurethane, polyimide, etc. These materials have good mechanical properties and thermal stability and can remain stable under high temperature and high pressure conditions.

Application fields of silicone-free thermal pads

Silicone-free thermal pads are widely used in many fields, especially in places that are sensitive to silicon contamination. The main application areas include:

1. Electronics and electrical: In the fields of hard disks, optical communications, high-end industrial control, medical electronics, etc., silicone-free thermal pads are used for thermal management of semiconductor devices, micro heat pipe radiators, memory modules and other products, effectively reducing the contamination of sensitive components such as screens and lenses caused by the volatilization of silicone oil, ensuring stable operation of the equipment.

2. Automotive electronics: Automotive electronic components have high requirements on temperature and environment. Silicone-free thermal pads can provide reliable heat dissipation under harsh conditions.

3. Telecommunication equipment: In special fields such as telecommunication hardware and equipment, silicone-free thermal pads have become an important part of thermal management solutions due to their excellent thermal conductivity and reliability.

Advantages and Challenges of Silicone-Free Thermal Pads

Advantages

1. Avoid pollution: It does not contain silicone oil, thus avoiding the pollution problems caused by the volatilization and migration of silicone oil. It is especially suitable for applications that are sensitive to silicone pollution.

2. High stability: In high temperature and high pressure environment, the performance is stable, not easy to age, and suitable for long-term continuous working conditions.

3. Environmental protection: Silicon-free materials are more environmentally friendly during production and use, which helps reduce environmental pollution.

Challenges

1. High cost: The production process of silicone-free thermal pads is relatively complicated, the material cost is high, and the price is slightly more expensive than traditional silicone-containing pads.

2. Market acceptance: Although silicone-free thermal pads have obvious advantages in certain application scenarios, their acceptance in the market still needs to be improved and it will take time to promote them.

In conclusion

As a new type of thermal conductive material, silicone-free thermal pads are gradually occupying an important position in the electronics industry with their unique advantages. In the future, silicone-free thermal pads will continue to promote the development of electronic equipment heat dissipation technology and make greater contributions to improving equipment performance and reliability.