As the integration of power devices in electronic products becomes higher and higher, the requirements for internal heat dissipation are also higher. Effectively reducing heat accumulation is the biggest key to improve the service life and reliability of the product.

——The power supply module is mainly used for CPU and GPU, and is usually composed of four components: capacitors, inductors, MosFET field effect tubes and PWM pulse width modulation chips. Others like IGBT, SiC, GaN driver etc.

The power module radiator is working, the heat generated is very large. If the power module does not dissipate heat well, the temperature is too high and may cause the power module to burn out, which may further damage the entire circuit board. The traditional high-power inverter power module is set on the circuit board, and the radiator is also set on the circuit board. The power module is in contact with the radiator. When the circuit is working, the heat generated by the power module is quickly dissipated by the radiator.

If the circuit power is large, the number of power supply modules will be relatively large. According to the current power supply module heat dissipation structure, the length of the radiator and the circuit board can only be increased to provide heat dissipation for all power supply modules , which will increase the volume of the chassis. At the same time, this heat dissipation structure has poor heat dissipation effect. Some high-power inverter power supply modules will install ventilation paper to dissipate heat, but it is troublesome to install ventilation paper. Therefore, the power supply module has very high requirements for heat dissipation. The heat dissipation conditions are divided into the lowest and highest, that is, the upper and lower floating range of the heat dissipation during operation. Generally, the worst heat dissipation condition is usually used as the standard when purchasing, so that the maximum safety margin can be left when using it, and the normal operation of the system can be ensured even at high temperatures.

The power supply module and the heat sink are currently fastened with screws. The power supply module is a device that generates a lot of heat, so it is usually equipped with a heat sink when in use, usually a small aluminum heat sink. In order to improve the heat dissipation performance, the heat of the power supply module must be transferred to the heat sink as much as possible, and the thermal resistance between the power supply module and the heat sink needs to be reduced. So what kind of thermal conductive insulation material is better?

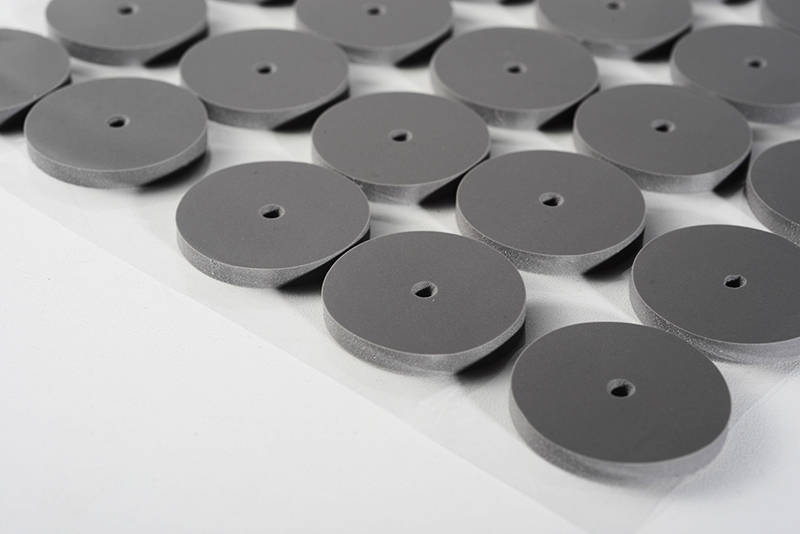

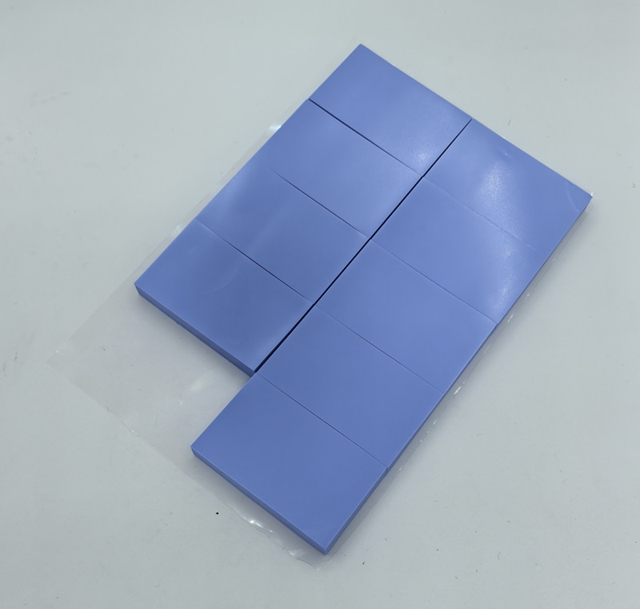

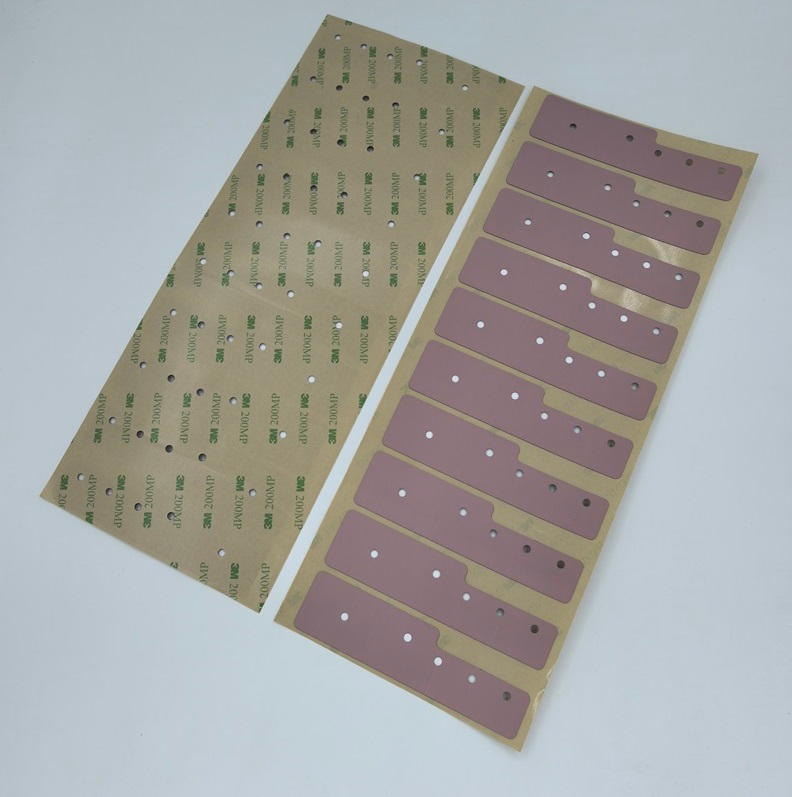

When disassembling some electronic products, I have seen soft thermal pads used. We thinks that soft thermal pads are still not very safe, because they are not strong enough and can easily damage the glue layer and cause breakdown when screwing. Therefore, thermal insulation sheets are generally used. The strength of the thermal insulation sheet must also be considered, and it must withstand a certain amount of force from tightening without being damaged.

The use of fireproof UL-94 V0 PC, high hardness thermal conductive silicone above 50 degrees, graphene thermal conductivity, copper aluminum foil, epoxy resin board and other common heat dissipation materials are recommended by Lanxin Industry. We have a supply chain with various specifications and parameters.

It is worth mentioning that the power supply module usually adopts the design of heat sink plus thermal conductive silicone for direct contact heat dissipation. If the power supply module shell cannot be grounded, it can be isolated with an insulating gasket(PC, Epoxy board, Thermal Tape, Mylar etc) and then heat dissipated with thermal conductive silicone grease. You can also use silicone sheets to cover the power supply module , which can not only dissipate heat but also prevent electrostatic damage.

Installing thermally conductive insulating materials between the power supply module and the heat sink can significantly reduce the interface thermal resistance, increase the heat dissipation efficiency, ensure that the operating temperature of the power supply module is maintained within a reasonable range, and enable the system to operate stably and reliably.