Materials that are both thermally conductive and have good insulating exist, and these materials are very important in the electronic and electrical fields because they can help dissipate heat while maintaining electrical isolation. These materials are usually made by adding specific thermally conductive fillers or using special preparation processes to improve their thermal conductivity while maintaining their insulating properties.

Thermal Interface Materials (TIMs) are materials used to fill the tiny gaps between two contacting surfaces to improve the efficiency of heat conduction. In electronic devices, TIMs are used to connect heat sources (such as CPUs or GPUs) and heat sinks (such as heat sinks or radiators) to help dissipate heat and keep the device operating temperature within a reasonable range. Thermally conductive and insulating materials are particularly important in this field because they not only need to conduct heat efficiently, but also provide electrical isolation.

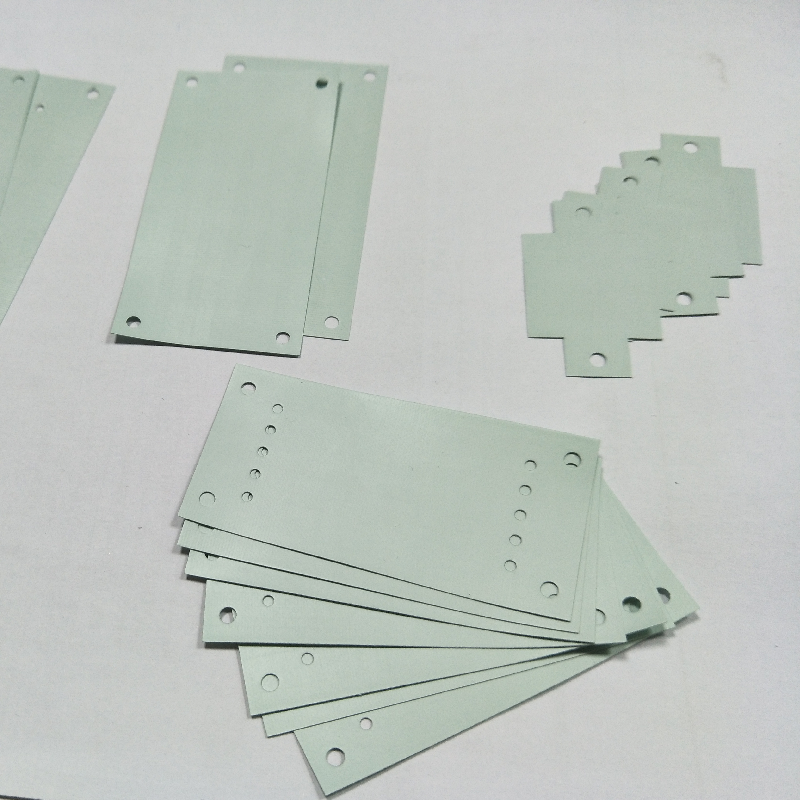

Apple Mac series ac adapter thermal pad module

Here are some of the ways thermally conductive and insulating materials are used in TIMs:

1. Thermal Grease: Thermal grease is a common TIM that consists of a silicone oil base filled with thermally conductive fillers such as aluminum oxide or aluminum nitride. These fillers provide good thermal conductivity, while the silicone oil base provides electrical insulation. Grease is usually applied in a thin layer between the heat source and the heat sink to fill the microscopic uneven surface, thereby improving the efficiency of heat conduction.

2. Thermal Pads: Thermal pads are TIMs made of an elastic material (such as silicone rubber) and a thermally conductive filler (such as alumina). They can be compressed to fill surface gaps and provide good thermal conduction and electrical insulation. Thermal pads are easy to install and are suitable for applications with uneven surfaces or where a certain degree of flexibility is required.

3. Phase Change Materials (PCMs): PCMs change from solid to liquid or from liquid to solid at a specific temperature, absorbing or releasing heat in the process. Some PCMs have both thermal conductivity and insulating properties, which can provide additional heat absorption when electronic devices are started up, and then maintain thermal conductivity during stable operation.

4. Thermal Tape: Thermal tape is a sticky TIM that is usually made of a polymer film with thermally conductive fillers. Thermal tape is easy to apply and provides a certain degree of thermal conductivity and electrical insulation.

5. Thermal Potting Compounds: Thermal potting compounds are a type of TIM used to encapsulate electronic components. They can provide structural strength, thermal conductivity, and electrical insulation after curing. These materials are often used to protect sensitive electronic components from environmental factors.

6. Silicone Rubber: Silicone rubber-based composite materials can be made into materials that are both thermally conductive and have certain insulating properties by filling them with thermally conductive fillers such as alumina or aluminum nitride.

7. Thermally Conductive Epoxy Resin: By adding thermally conductive fillers to epoxy resin, a composite material with good thermal conductivity and certain insulation properties can be obtained.

8. Thermally Conductive Gels: Certain thermally conductive gels combine thermal conductivity and insulation for applications that require flexibility and good thermal management.

When selecting a TIM, factors such as thermal conductivity, thermal resistance, compressibility, adhesion, mechanical strength, chemical stability, electrical insulation, and cost need to be considered. Thermally conductive and insulating materials can meet the dual needs of electronic devices in terms of heat dissipation and electrical safety, so they are very critical in the application of TIMs.

If you don’t know which type of thermal conductive material to choose, please contact Lanxin Industrial. With over 20 years of experience in the thermal management material application industry and can provide you with excellent solutions. The selection of the right material depends on the requirements of the specific application, such as thermal conductivity, insulating properties, mechanical strength, processability, and cost.