Product description

Conductive silicone keypads are integral input components widely used in a variety of electronic devices. These keypads are constructed using a combination of silicone rubber and conductive materials, endowing them with unique properties for efficient user - device interaction. Silicone rubber forms the base structure of the keypad, providing flexibility and durability. Its pliable nature allows users to press the keys with ease, offering a comfortable tactile feedback. The material is also highly resistant to environmental factors such as moisture, dust, and chemicals. This makes conductive silicone keypads suitable for use in diverse conditions, from the humid environments of kitchens where appliances with such keypads might be used, to the dusty workshops where industrial control panels with these keypads are installed.

The conductive aspect of the keypad is achieved by incorporating conductive particles, typically carbon - based or metal - filled materials, into the silicone rubber. When a user presses a key, the conductive part of the keypad comes into contact with the underlying circuit board. This contact completes an electrical circuit, sending a signal to the device's processor. The precision of this electrical connection is crucial for accurate input recognition, whether it's a simple button press on a remote control or a complex sequence of inputs on a calculator.

| ITEM | Custom Molding Rubber Keypad |

| Type | Rubber Screen Print Keypad, Rubber Laser Etching Keypad, Rubber Epoxy Keypad, Plastic+Rubber Keypad(plastic cap+silicone rubber pad), Rubber PU Coating Keypad, etc... |

| Certificate | IATF 16949:2016 / ISO 9001:2015 / ISO 45001:2018 / ISO 14001:2015 /REACH/ROHS/MSDS/LFGB/F D A |

| Drawing Format | .stp / .step / .igs /.stl /.dwg / .pdf |

| Function | Industrial parts /daily supply / Automotive/ Medical device, etc... |

Images for reference

Producing Process

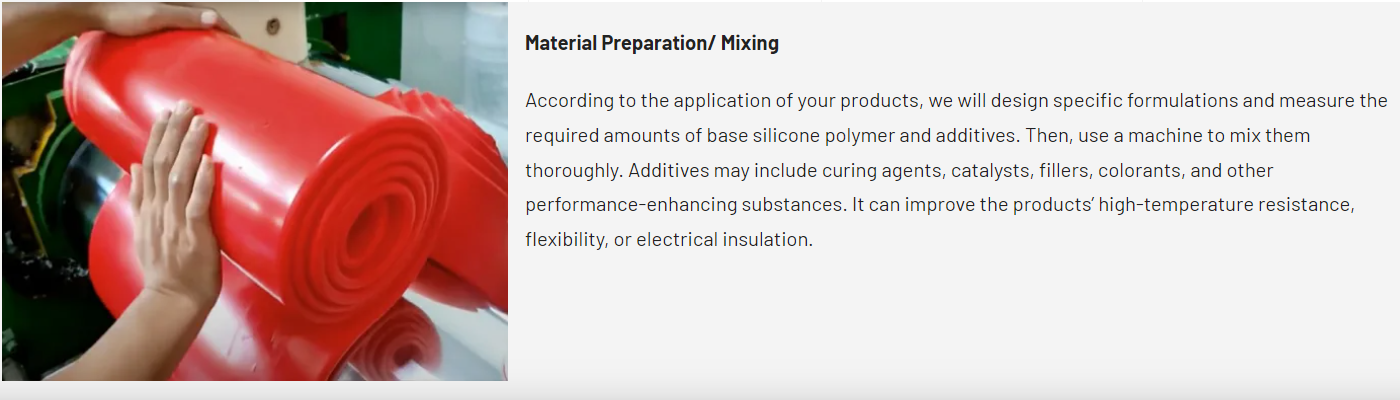

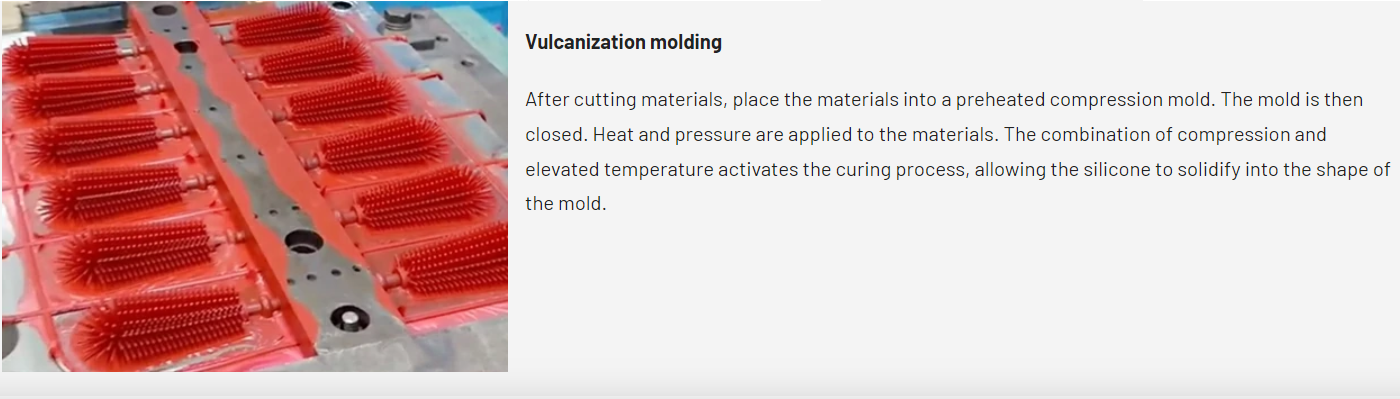

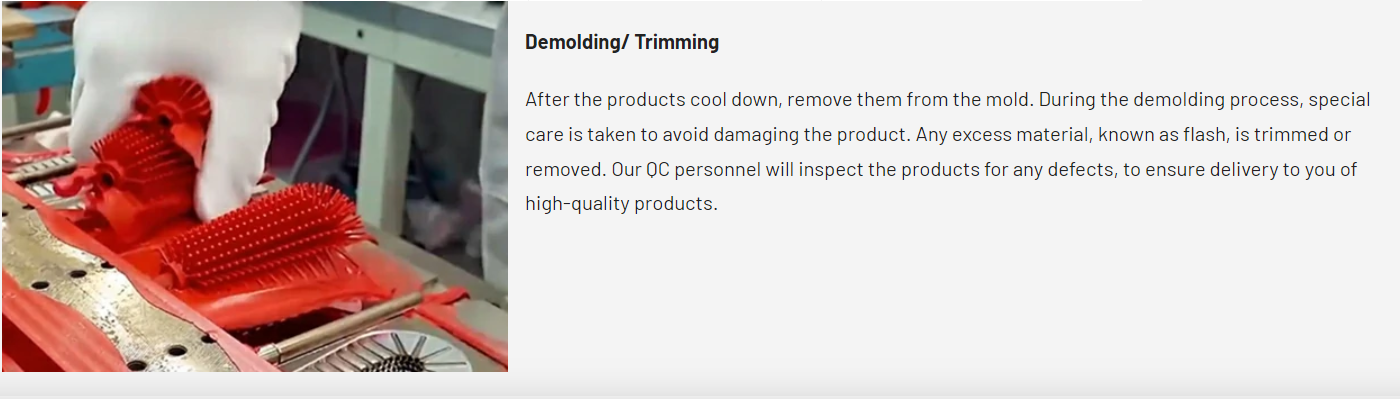

The manufacturing process of conductive silicone keypads begins with the formulation of the silicone rubber compound. The conductive particles are carefully mixed into the silicone to ensure an even distribution. Once the compound is ready, it is shaped using molding techniques. Compression molding is a common method, where the silicone compound is placed in a mold and compressed under heat and pressure to take on the shape of the keypad, including the individual key shapes. Injection molding can also be used, where the molten silicone - conductive particle mixture is injected into a mold cavity. After molding, the keypads may undergo additional processes such as surface treatment to enhance the conductivity of the contact areas and to improve the overall appearance and feel of the keys.

Quality standard

Lanxin's rubber keypad quality is 100% according to ISO9001 Standard. We seriously take care of the quality control from IQC to OQC, throughout each step of the production.

Lanxin dedicated to strict quality control and thoughtful customer service. We strive to exceed our customers' expectation in all aspects of product manufacturing process, and recognize our great responsibilities to our customers.

FAQ

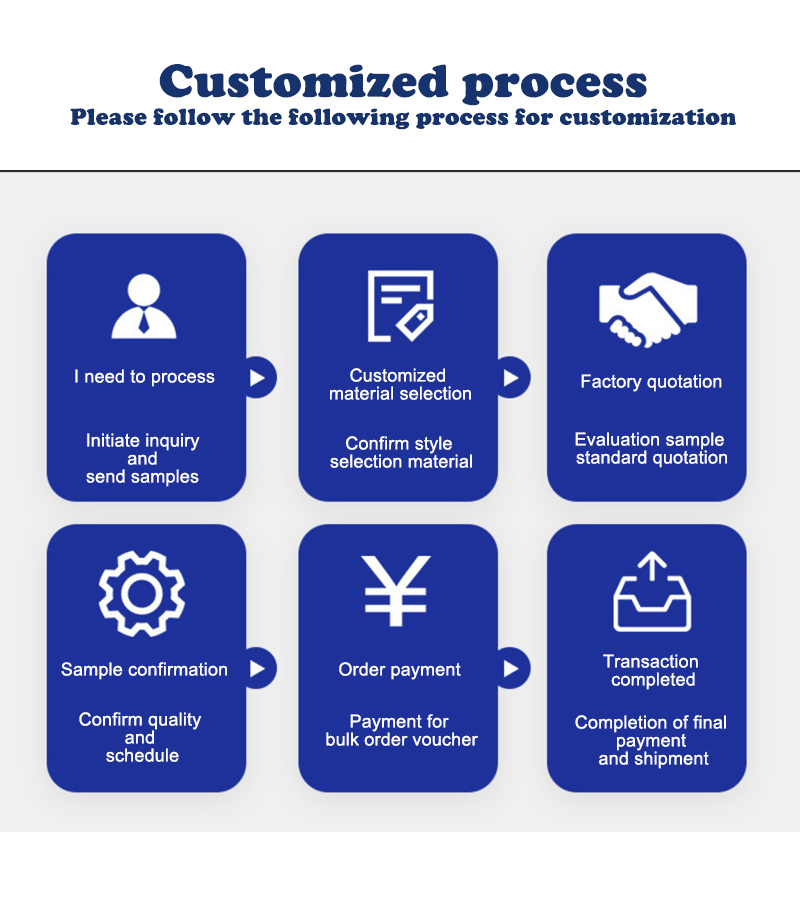

Q1: How soon can I get a precise quotation for custom silicone rubber keypad?

A1: Please send us your inquiry by email or phone call. Once we confirm the design (Feature details with parameters), material, color, qty, we can provide quotation within 24 HOURS.

Q2: Can I get a free sample, how long will it take?

A2: a. For standard products we have in stock, YES for free sample, but the express fee will be charged in advance. Mostly, it takes 3-10 days.

b. For custom products, sample fee is determined by the detailed sample requirements. Normally, it takes 7-15 days.

Q3: Can you make custom parts based on my sample?

A3: Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing for production.

Q4: What does your OEM service include?

A4: We follow up your request from the design idea to the bulk production.

a. You can provide 3D drawing to us, then our engineers and production teams evaluate the design and quote you the precise cost.

b. If you don’t have 3D drawing, you can provide 2D drawing or draft with features details with full dimensions, we can draft 3D drawing for you with fair charge.

c. You can also customize Logo on the product surface, package, color box or carton.

d. We also provide assembly service for the OEM parts.

Q5. What is your payment term?

A5: We accept T/T, Paypal, Western Union, L/C, Alibaba Trade Assurance.