Product description

Conductive silicone button switches are fundamental components in electronic devices, enabling user - initiated electrical connections. These switches combine the unique properties of silicone rubber with conductive elements, resulting in a reliable and user - friendly input solution. In the realm of instrument keyboards, silicone rubber has emerged as a popular choice. Silicone rubber instrument keyboards offer a unique set of advantages. They are highly durable, resistant to wear and tear even with frequent use. Their soft-touch feel provides a comfortable typing experience, which is crucial for operators who use instrument keyboards for extended periods. Additionally, silicone rubber has excellent insulation properties, ensuring the safety of electrical components within the instrument.

Conductive silicone button switches find extensive use in various industries. In medical equipment, for instance, the hygienic nature of silicone rubber makes it ideal for instrument keyboards, as it can be easily cleaned and sanitized, reducing the risk of cross - contamination. In industrial control panels, the durability and resistance to harsh environmental conditions of silicone rubber keyboards make them reliable for continuous operation. When considering the overall design of instruments, EVA gaskets often work in tandem with silicone rubber instrument keyboards. The different hardness levels of EVA gaskets play a role here. For example, the 15 - 25 Shore A (high - elastic EVA) gaskets can be used to provide additional cushioning around the keyboard area, protecting the underlying components from vibrations that might be generated during typing or transportation. The 38 Shore A (ordinary EVA) gaskets can be employed for basic sealing purposes, ensuring that dust and small particles do not infiltrate the instrument through the keyboard's edges. This combination of silicone rubber instrument keyboards and EVA gaskets showcases how different materials can collaborate to enhance the performance and functionality of instruments in diverse applications.

Images for reference

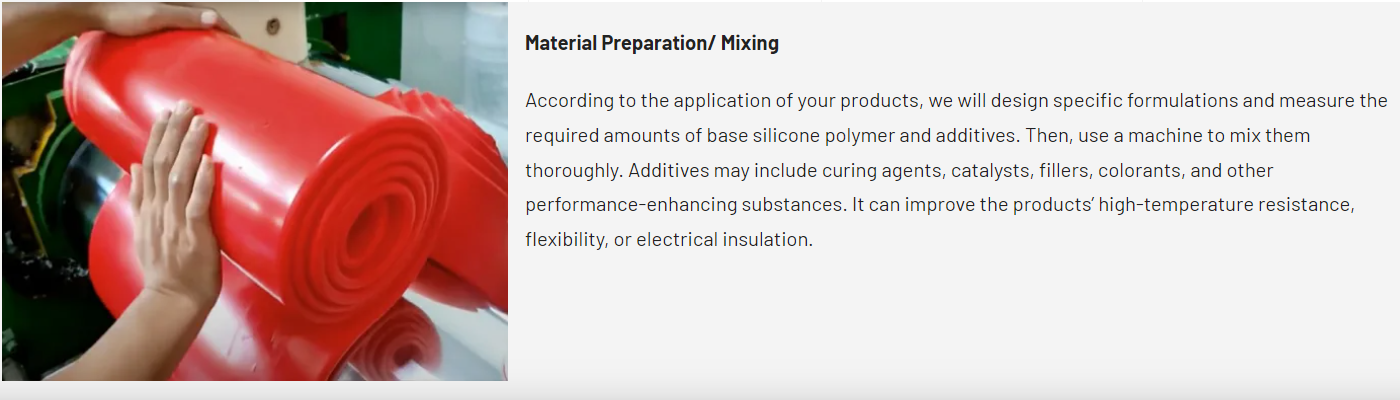

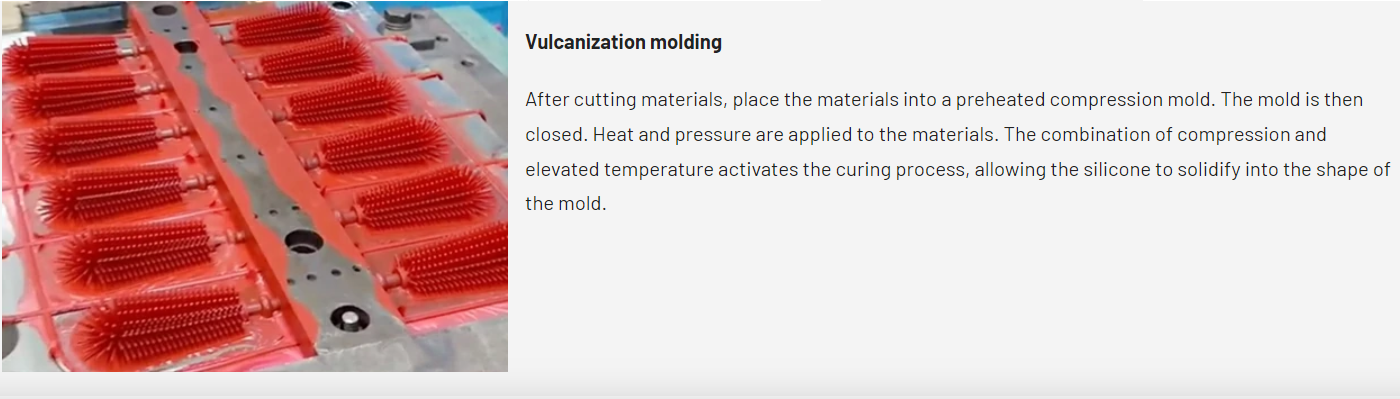

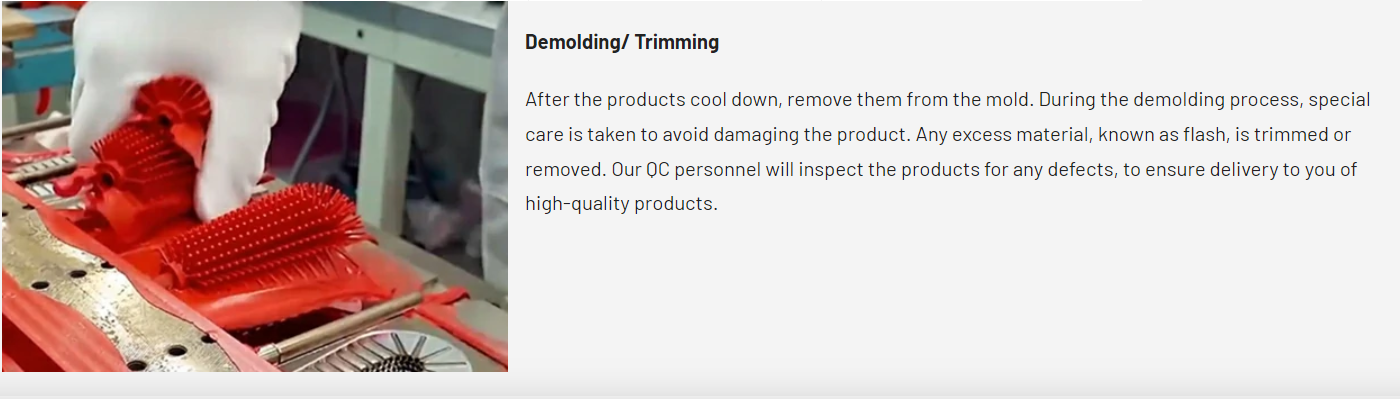

Producing Process

Quality standard

Lanxin's rubber keypad quality is 100% according to ISO9001 Standard. We seriously take care of the quality control from IQC to OQC, throughout each step of the production.

Lanxin dedicated to strict quality control and thoughtful customer service. We strive to exceed our customers' expectation in all aspects of product manufacturing process, and recognize our great responsibilities to our customers.

FAQ

Q1: How soon can I get a precise quotation for custom silicone rubber keypad?

A1: Please send us your inquiry by email or phone call. Once we confirm the design (Feature details with parameters), material, color, qty, we can provide quotation within 24 HOURS.

Q2: Can I get a free sample, how long will it take?

A2: a. For standard products we have in stock, YES for free sample, but the express fee will be charged in advance. Mostly, it takes 3-10 days.

b. For custom products, sample fee is determined by the detailed sample requirements. Normally, it takes 7-15 days.

Q3: Can you make custom parts based on my sample?

A3: Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing for production.

Q4: What does your OEM service include?

A4: We follow up your request from the design idea to the bulk production.

a. You can provide 3D drawing to us, then our engineers and production teams evaluate the design and quote you the precise cost.

b. If you don’t have 3D drawing, you can provide 2D drawing or draft with features details with full dimensions, we can draft 3D drawing for you with fair charge.

c. You can also customize Logo on the product surface, package, color box or carton.

d. We also provide assembly service for the OEM parts.

Q5. What is your payment term?

A5: We accept T/T, Paypal, Western Union, L/C, Alibaba Trade Assurance.