Product description

Many of the die-cutting materials we work with are already used in a variety of industries:

| ITEM | Epdm rubber seals/gaskets | ||

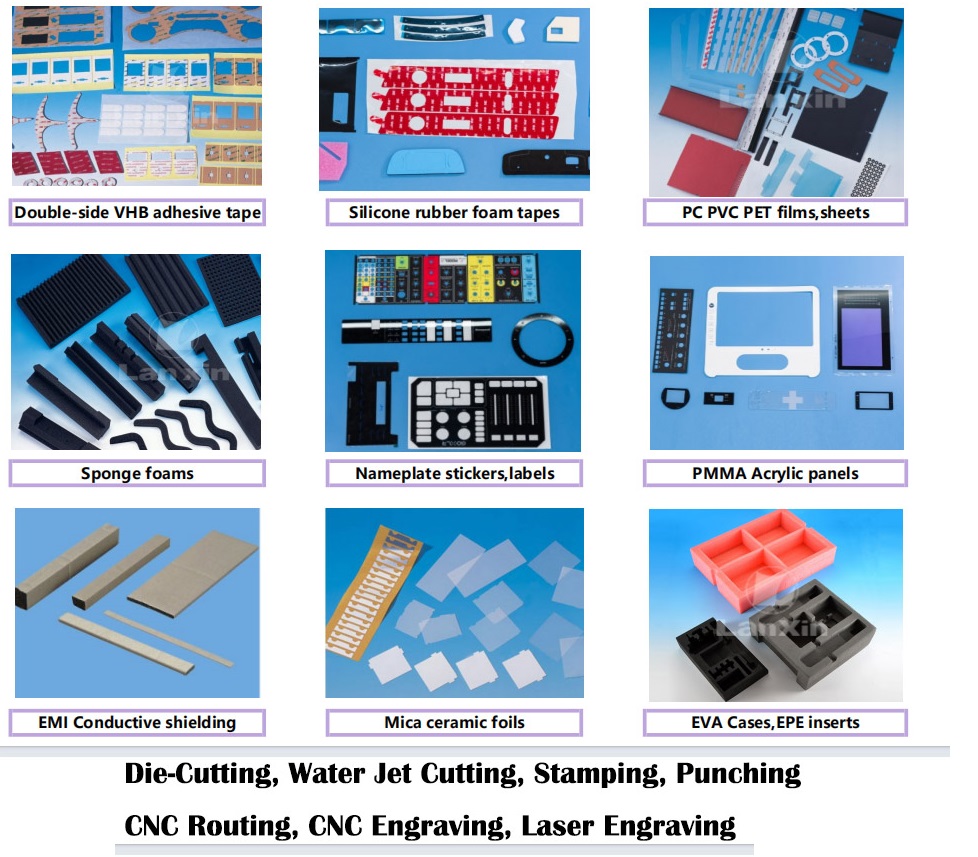

| Material | Die-Cutting materials can improve efficiency and output quality. Here are just a few of the materials that we can die-cut:

|

| Certificate | IATF 16949:2016 / ISO 9001:2015 / ISO 45001:2018 / ISO 14001:2015 /REACH/ROHS/MSDS/LFGB/F D A |

| Drawing Format | .stp / .step / .igs /.stl /.dwg / .pdf |

| Cutting types | Rotary die-cutting, flatbed die-cutting, waterjet cutting, CNC, etc... |

Fireproof EPDM rubber gaskets are specialized sealing components designed to meet stringent safety requirements in environments where fire risks are a concern. These gaskets are made from Ethylene Propylene Diene Monomer (EPDM) rubber, which has been engineered to possess fire - resistant properties. EPDM rubber, in its base form, already offers a host of favorable characteristics. It is highly flexible, allowing fireproof EPDM rubber gaskets to conform to different shapes and surfaces with ease. Whether sealing irregularly shaped machinery parts or complex joints, the gasket can adapt to ensure a tight fit.

The fire - resistant nature of these gaskets is achieved through a combination of factors. Specialized fire - retardant additives are incorporated into the EPDM rubber compound during the manufacturing process. These additives work by either releasing non - combustible gases when exposed to high temperatures, which dilutes the oxygen available for combustion, or by forming a protective char layer on the surface of the gasket. This char layer acts as a barrier, preventing the underlying rubber from further burning and slowing down the spread of fire.

In terms of chemical resistance, fireproof EPDM rubber gaskets inherit the excellent chemical resistance of regular EPDM rubber. They can resist a wide range of chemicals, including acids, alkalis, and many solvents. This makes them suitable for use in industrial settings where they may come into contact with potentially corrosive substances, while also maintaining their fire - resistant properties. Fireproof EPDM rubber gaskets offer a reliable and versatile solution for sealing applications in fire - prone environments. Their combination of fire resistance, flexibility, chemical resistance, and efficient manufacturing processes makes them an essential component in ensuring the safety and proper functioning of various structures and systems.

Images for reference

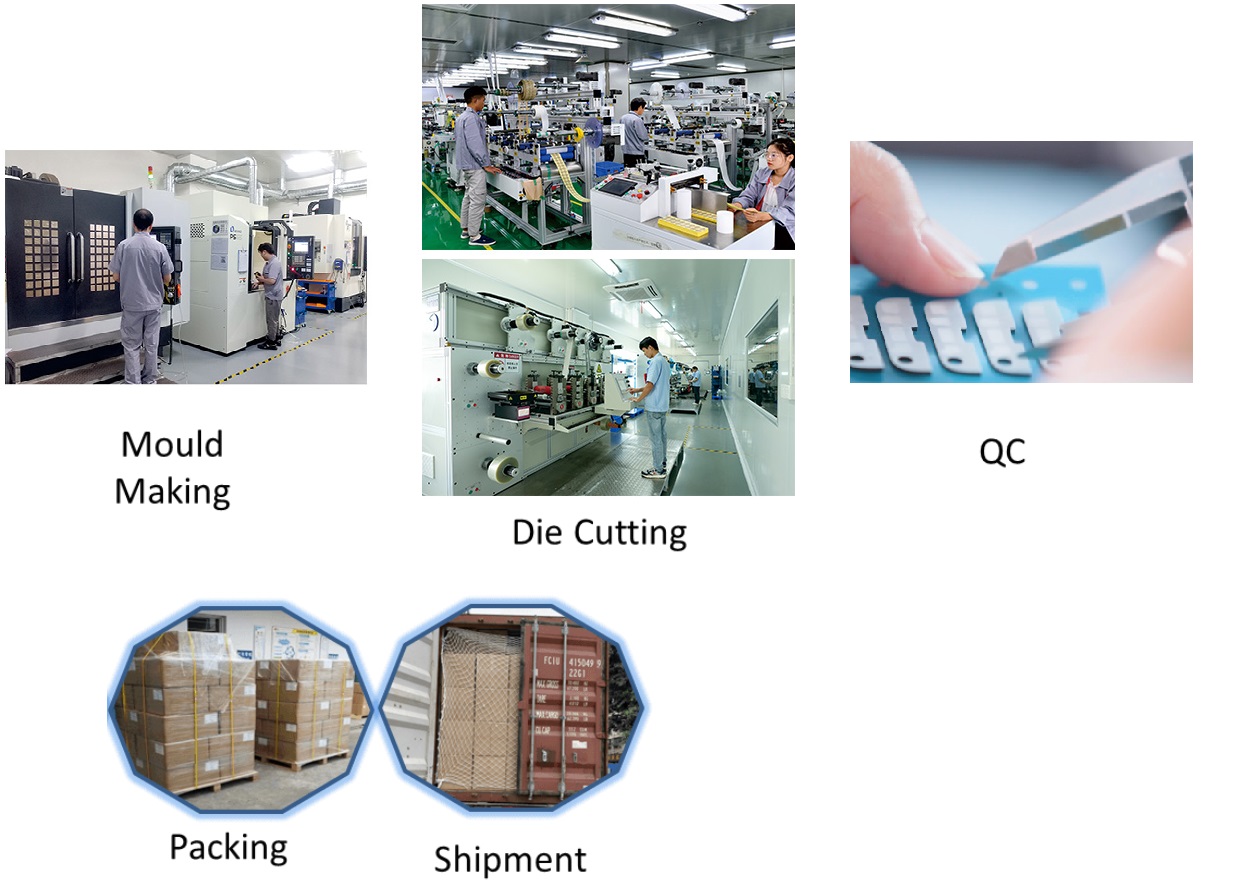

Producing Process

The manufacturing process of fireproof EPDM rubber gaskets starts with the careful selection of EPDM rubber and the precise formulation of the fire - retardant additives. The rubber compound is then mixed thoroughly to ensure an even distribution of the additives. After that, it can be shaped using methods such as compression molding or injection molding. In compression molding, the rubber is placed in a mold and subjected to heat and pressure to take on the desired shape. Injection molding involves injecting the molten rubber compound into a mold cavity. Post - molding, the gaskets may undergo additional treatments like trimming to achieve accurate dimensions and surface finishing to enhance their sealing performance.

Quality standard

Lanxin's insulation materials quality is 100% according to ISO9001 Standard. We seriously take care of the quality control from IQC to OQC, throughout each step of the production.