Product description

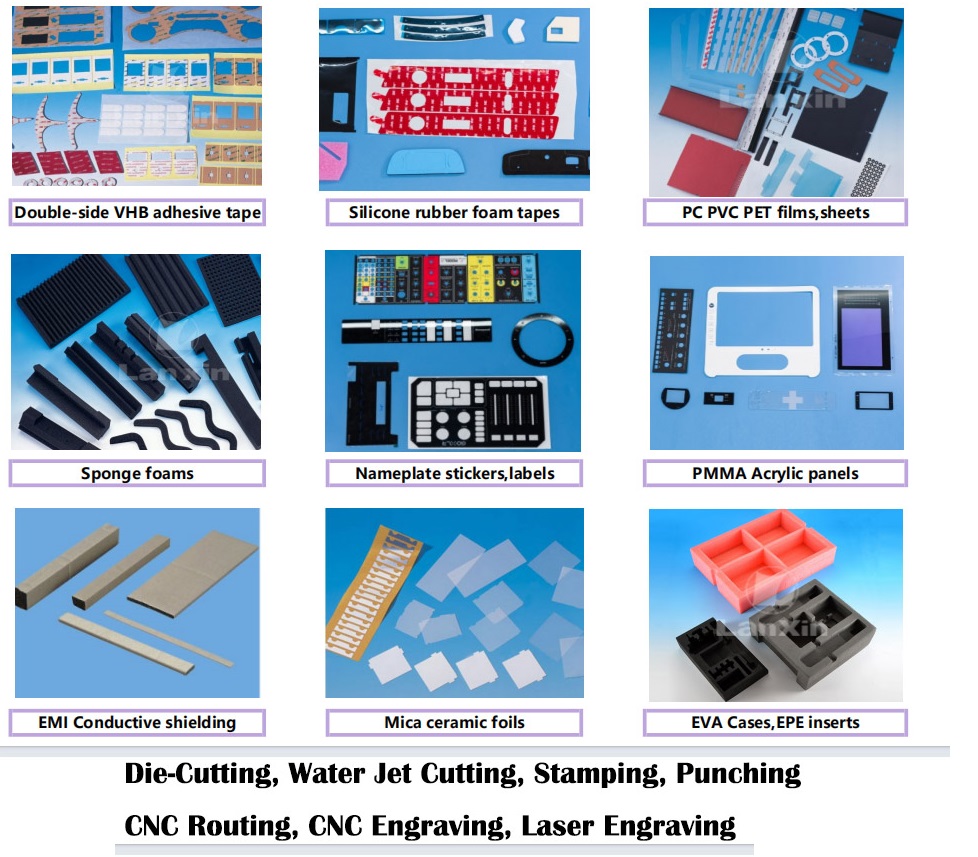

Many of the die-cutting materials we work with are already used in a variety of industries:

| ITEM | EVA mats/gaskets |

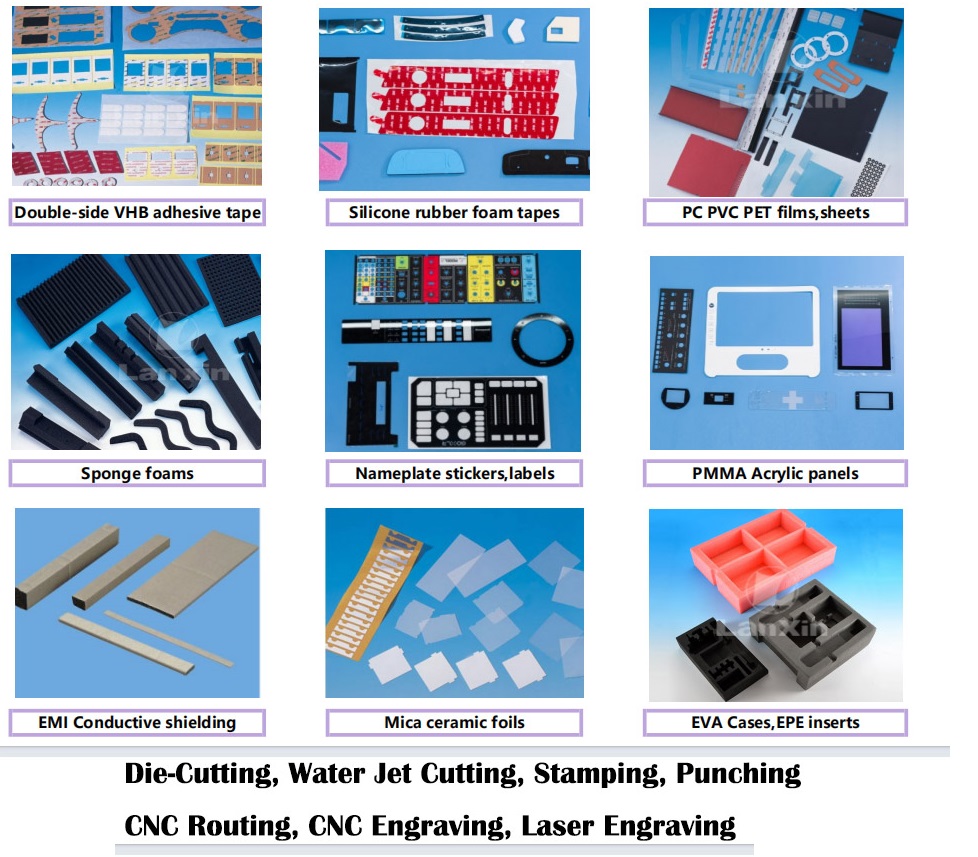

| Material | Die-Cutting materials can improve efficiency and output quality. Here are just a few of the materials that we can die-cut:

| Pressure-Sensitive Tapes Gaskets Films Foams Foils Papers Rubbers Label Stocks VHB Specialty Materials

|

|

| Certificate | IATF 16949:2016 / ISO 9001:2015 / ISO 45001:2018 / ISO 14001:2015 /REACH/ROHS/MSDS/LFGB/F D A |

| Drawing Format | .stp / .step / .igs /.stl /.dwg / .pdf |

| Cutting types | Rotary die-cutting, flatbed die-cutting, waterjet cutting, CNC, etc... |

EVA material has good flexibility and elasticity, and die-cutting EVA gaskets can be easily deformed to fit different shapes and sizes of gaps, providing a good sealing effect. It has strong resistance to organic solvents, acids, alkalis and other chemicals, which can ensure the stability of the gasket in different chemical environments. The water absorption of EVA is very low, which can effectively prevent water from penetrating into the sealed area, playing a good waterproof role. It has certain sound insulation and noise reduction effects, which can reduce noise and vibration in some applications.

EVA Foam Tape: It is made of environmentally friendly closed-cell EVA foam with a thickness range of 0.5mm to 15mm. It can be coated with acrylic solvent or hot melt adhesive on one or both sides and combined with release paper. It has excellent sealing, shock absorption, weather resistance, oil resistance, corrosion resistance and sound absorption properties.

Lanxin EVA Foam Gaskets: They offer EVA foam in two densities, with sheets of different sizes. The thickness range is from 1/16" to 3". They can be die cut to size and supplied with an adhesive backing, and are available in black, gray and natural (off-white) colors.

Automotive Industry: They are used in automotive doors, windows and sunroofs for sealing to prevent dust, rain and wind from entering the vehicle. They can also be found in the interior of vehicles, such as around the instrument panel and door panels, playing a role in shock absorption and noise reduction.

Electronics Industry: In the production of electronic products like smartphones, tablets and laptops, die-cutting EVA gaskets are used to seal the gaps between components and the shell, protecting the internal components from dust and moisture. They are also used for cushioning and shock absorption of hard drives and other components to reduce the impact of vibration.

Construction Industry: They are often used in the installation of doors and windows to fill the gaps and improve the sealing performance, playing roles in heat preservation, sound insulation and waterproofing. In addition, they can be used in the joints of building walls and floors to buffer vibrations and thermal expansion and contraction.

Packaging Industry: They are used as cushioning materials in the packaging of delicate products such as glassware, ceramics and electronic equipment to prevent the products from being damaged by collision and shock during transportation and storage.

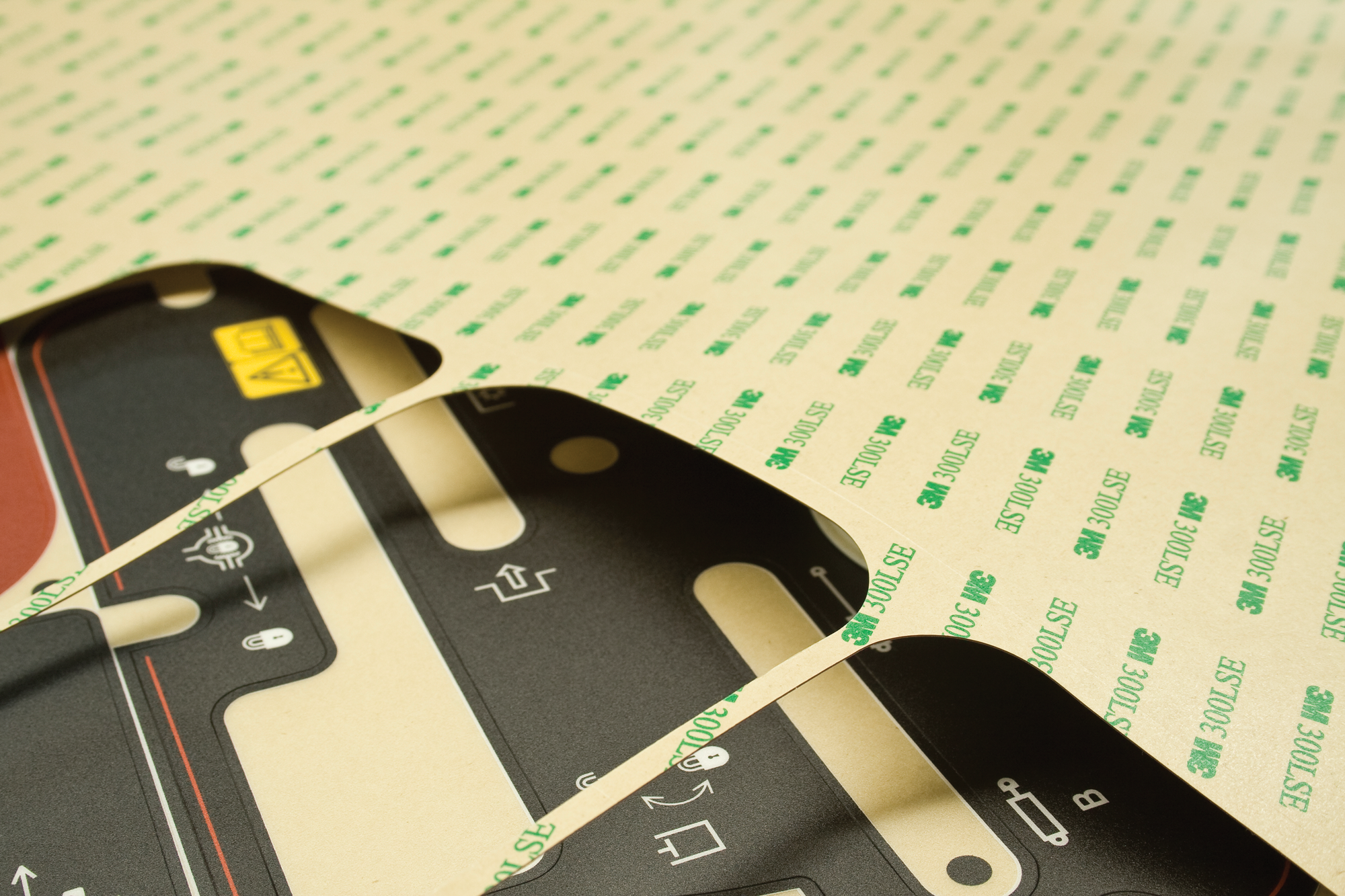

Images for reference

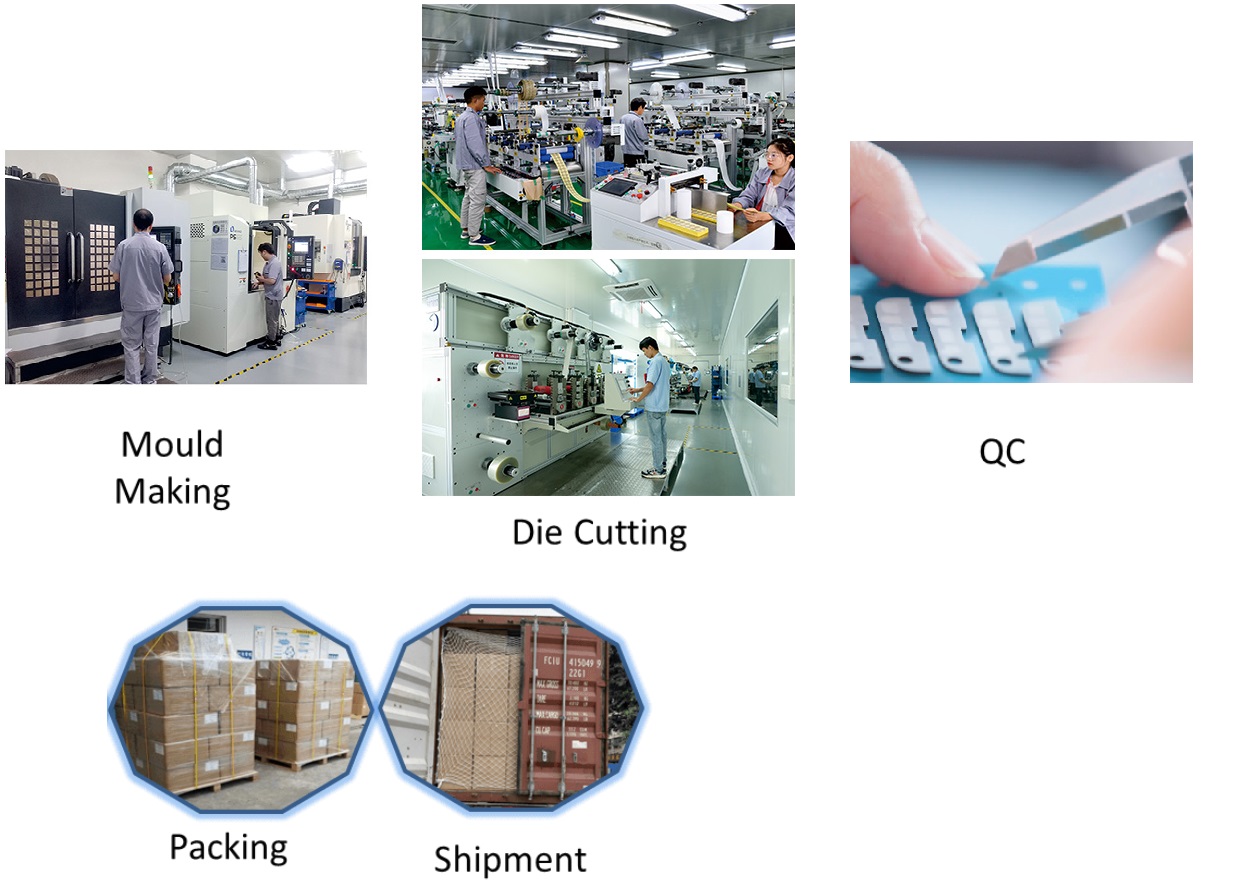

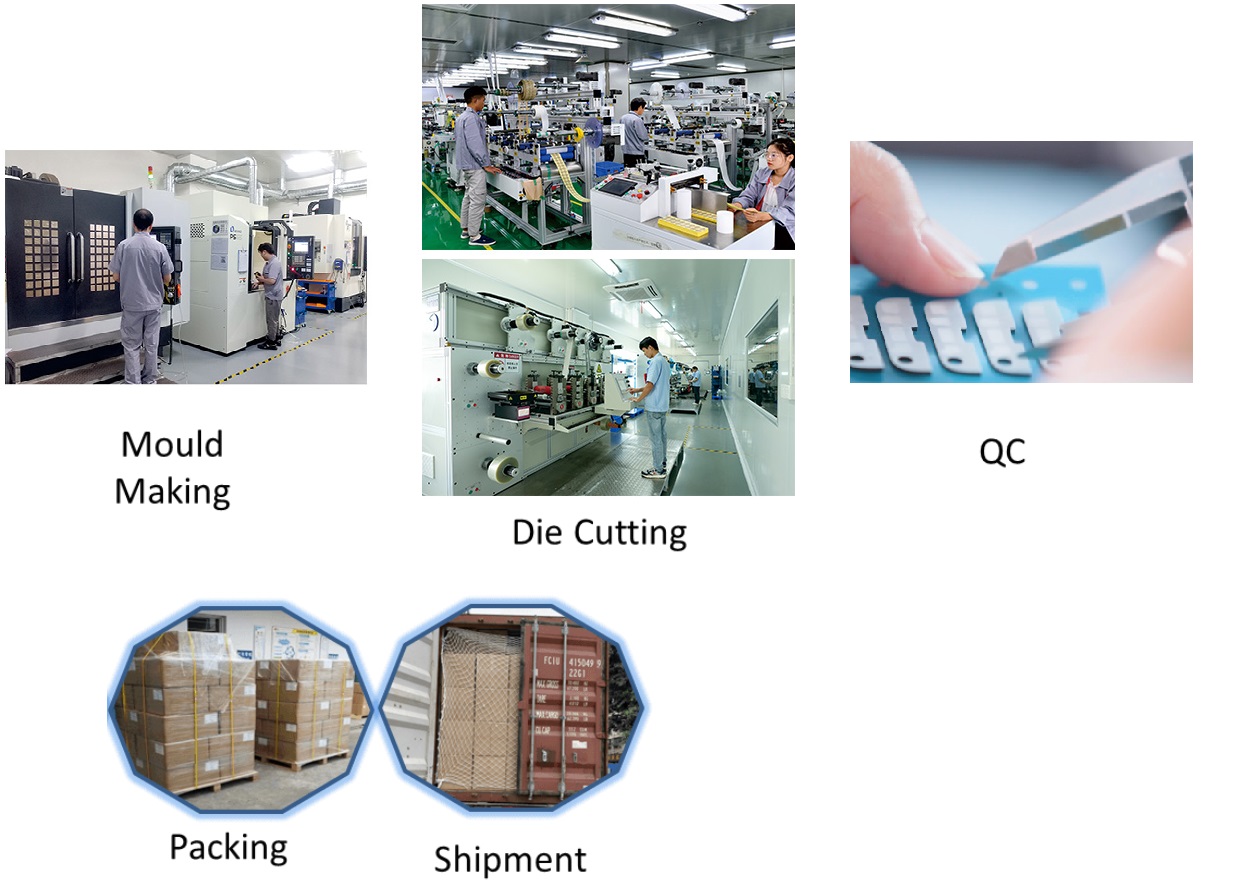

Producing Process

Quality standard

Lanxin's insulation materials quality is 100% according to ISO9001 Standard. We seriously take care of the quality control from IQC to OQC, throughout each step of the production.

Lanxin dedicated to strict quality control and thoughtful customer service. We strive to exceed our customers' expectation in all aspects of product manufacturing process, and recognize our great responsibilities to our customers.

FAQ

Q1: How soon can I get a precise quotation for custom die cutting insulated materials ?

A1: Please send us your inquiry by email or phone call. Once we confirm the design (Feature details with parameters), material, color, qty, we can provide quotation within 24 HOURS.

Q2: Can I get a free sample, how long will it take?

A2: a. For standard products we have in stock, YES for free sample, but the express fee will be charged in advance. Mostly, it takes 3-10 days.

b. For custom products, sample fee is determined by the detailed sample requirements. Normally, it takes 7-15 days.

Q3: Can you make custom parts based on my sample?

A3: Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing for production.

Q4: What does your OEM service include?

A4: We follow up your request from the design idea to the bulk production.

a. You can provide 3D drawing to us, then our engineers and production teams evaluate the design and quote you the precise cost.

b. If you don’t have 3D drawing, you can provide 2D drawing or draft with features details with full dimensions, we can draft 3D drawing for you with fair charge.

c. You can also customize Logo on the product surface, package, color box or carton.

d. We also provide assembly service for the OEM parts.

Q5. What is your payment term?

A5: We accept T/T, Paypal, Western Union, L/C, Alibaba Trade Assurance.