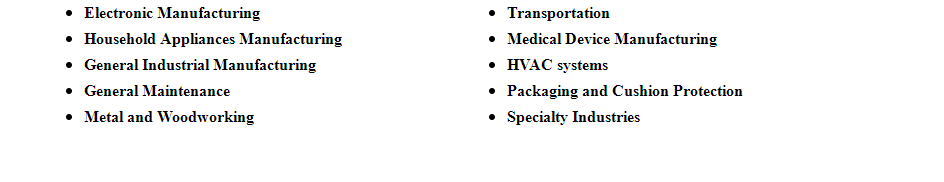

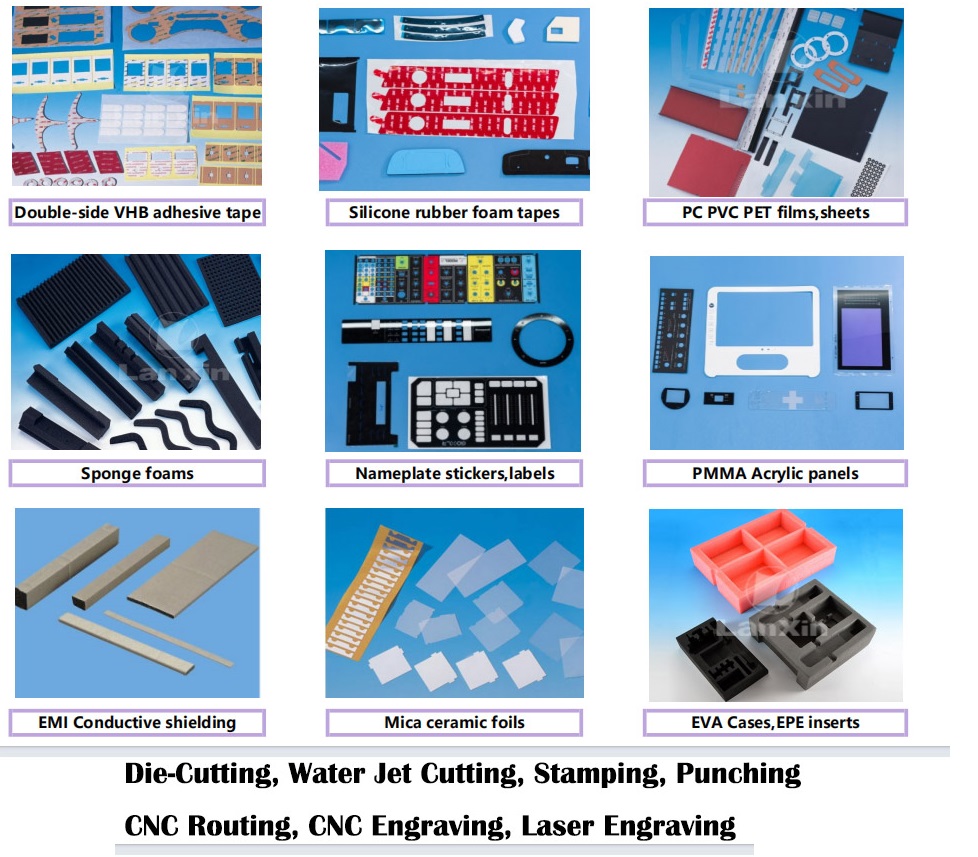

Many of the die-cutting materials we work with are already used in a variety of industries:

Silk - screen - printed PMMA Labels blend the precision of silk - screening with the unique qualities of PolyMethylMethAcrylate (PMMA, or acrylic). They're popular across many applications due to PMMA's characteristics and the printing process. PMMA is well - known for its excellent optical clarity, having a high light transmission like glass but being lightweight. This transparency makes PMMA Labels perfect for applications where clear visibility of printed content matters. Whether for eye - catching product labels or decorative ones, the clear PMMA substrate lets colors and graphics show vividly. Besides optical properties, PMMA offers good mechanical strength, being somewhat resistant to impacts and scratches, ensuring label integrity during normal use. Its lightweight yet durable nature, along with decent weather resistance (resisting sunlight and outdoor elements without much yellowing or degradation), makes it suitable for indoor and outdoor applications.

The silk - screen printing for PMMA Labels starts with creating a stencil (screen) with the desired design. A squeegee forces ink, carefully chosen to adhere to PMMA, onto the surface. Multiple screens are used for multi - colored designs. After application, the ink is cured, either by heat (exposing to a specific temp for a while) or UV light, ensuring a strong bond. In various industries, PMMA Labels have diverse uses. In electronics, they mark device casings. In fashion and beauty, they add elegance to packaging. In automotive, they're on interior components. Their design versatility allows for a wide range of colors, with thick - ink silk - screening resulting in high - quality, fade - resistant prints. Functionally, they display product info like ingredients and warnings, such as in the food and beverage industry on containers. In conclusion, silk - screen - printed PMMA Labels are a reliable and visually appealing option for identification, branding, and information. The combination of PMMA's optical, mechanical, and weather - resistant features with silk - screen printing precision makes them crucial in many industries, enhancing product functionality and aesthetics.

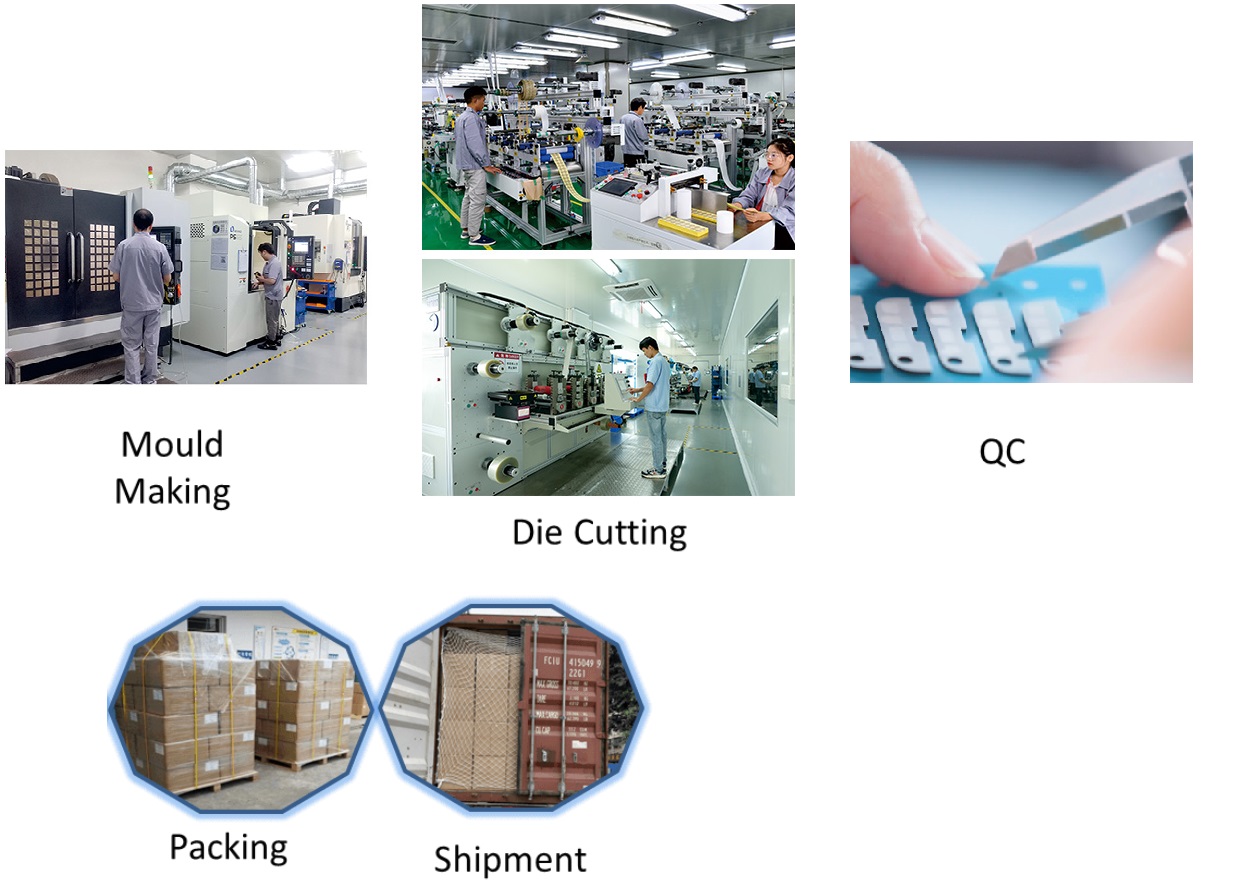

Lanxin's insulation materials quality is 100% according to ISO9001 Standard. We seriously take care of the quality control from IQC to OQC, throughout each step of the production.

Lanxin dedicated to strict quality control and thoughtful customer service. We strive to exceed our customers' expectation in all aspects of product manufacturing process, and recognize our great responsibilities to our customers.